The Complete dap fertilizer production process plays an increasingly important role in global agriculture and environmental protection, especially as more industries recognize that DAP is not just a fertilizer but also a widely used fire retardant. Today, many factories rely on advanced equipment systems to manage raw materials, mixing, lifting, batching, and packaging. As interest continues to rise, the Complete dap fertilizer production process is becoming a focus of innovation, efficiency improvements, and environmental planning. Much of the appeal comes from DAP’s unusual characteristic: it slows the spread of forest fires, and later, once the threat is gone, it breaks down into nutrients that plants can absorb—offering a rare combination of safety and agricultural value.

In this article, we’ll take a friendly, journalistic look at how the Complete dap fertilizer production process works, what equipment is essential, and how modern manufacturers keep production smooth and reliable. Whether you’re involved in agriculture, industrial engineering, or simply curious about how fertilizers are made, this walkthrough will make the journey surprisingly easy to follow.

DAP (diammonium phosphate) has long been essential to crop nutrition thanks to its high phosphorus and nitrogen content. But one of its lesser-known qualities is its ability to act as a fire retardant. When applied as part of wildfire-prevention strategies, it helps slow or block the spread of flames. Once the fire season ends, the residue becomes a nutrient-rich fertilizer. This impressive “two-in-one” effect gives extra importance to the Complete dap fertilizer production process, motivating many regions to modernize their production facilities.

Below, we trace the Complete dap fertilizer production process through each main stage and highlight the machines that keep everything running smoothly. It’s a fascinating blend of chemistry, engineering, and practical design.

Every production line begins with dependable raw-material storage. Ammonium sources, phosphates, and various additives must be kept dry, stable, and easily accessible. Large silos, sealed hoppers, and flow-stabilizing feeders prepare the materials before they move into the processing line.

Why this matters:

Reliable raw-material handling ensures consistent quality and uninterrupted production. Any moisture change or feeding inconsistency can disrupt the entire Complete dap fertilizer production process, so modern systems rely heavily on automation and real-time monitoring.

Once materials leave storage, they are usually lifted vertically using a bucket elevator. These tall, enclosed conveyors move materials gently to reduce damage.

Key features:

This machine plays a crucial role in maintaining an efficient Complete dap fertilizer production process, ensuring materials reach batching equipment without interruption.

Batching is all about precision. Each ingredient must be dosed accurately to achieve the correct nutrient balance—and to ensure the material behaves predictably when used as a fire retardant.

The dynamic batching scale uses controlled feeding mechanisms and sensors to measure flow in real time. It’s an essential part of any stable Complete dap fertilizer production process.

Why batching accuracy matters:

A small deviation can impact both agricultural effectiveness and environmental safety.

The rotary drum mixer is the heart of many production lines. Here, all components combine through continuous tumbling, blending, and sometimes granulation.

Typical advantages:

For producers aiming at long-term consistency, this mixer determines the stability of the entire Complete dap fertilizer production process, making it a centerpiece of most layouts.

After mixing, another bucket elevator usually lifts the blended materials to the next stage—whether cooling, screening, or direct storage.

The second elevator maintains the continuous flow essential to the Complete dap fertilizer production process, keeping equipment aligned vertically and minimizing floor-space usage.

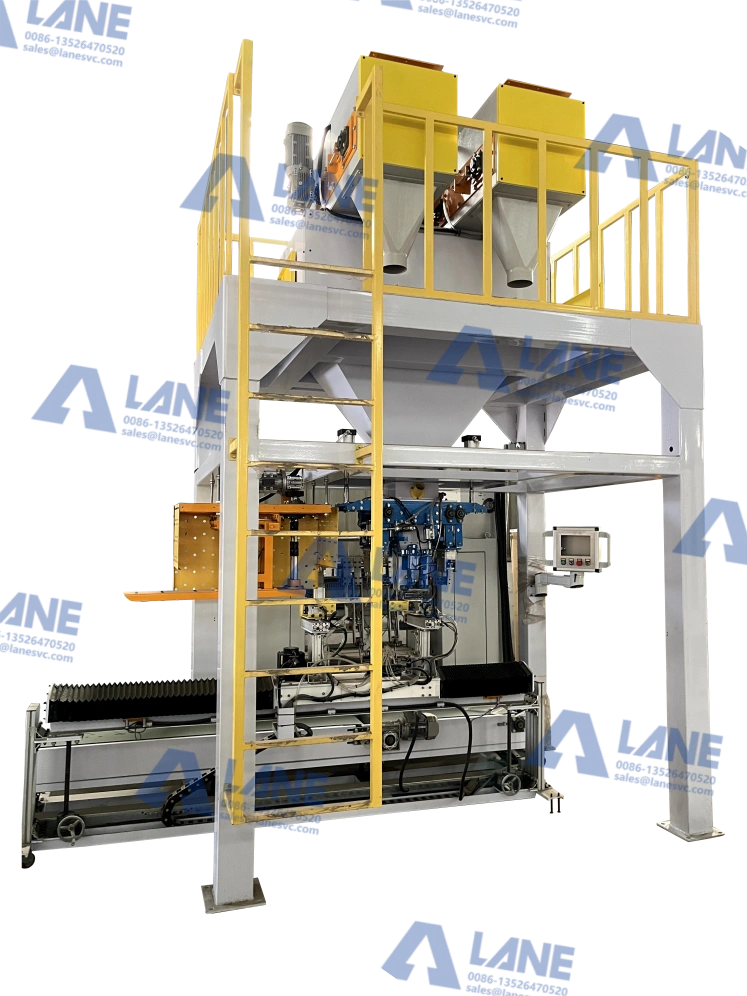

Once materials are processed, screened, and stabilized, it’s time for packaging. Whether products go into 25-kg bags, jumbo bags, or bulk containers, packaging machines ensure accuracy and minimal dust release.

Common features:

Proper packaging protects DAP’s nutrient content and preserves its fire-retardant qualities, completing the Complete dap fertilizer production process before final shipment.

The Dual Role of DAP: Fire Protection + Fertilizer

One of the most remarkable aspects of DAP is its double purpose. When applied as a fire retardant, it forms a protective line ahead of wildfires. It slows burning, provides firefighters crucial time, and reduces damage. Afterward, the same material decomposes naturally and becomes a nutrient source that helps forests or fields recover.

This dual nature is part of what makes the Complete dap fertilizer production process so valuable—not just for agriculture but also for environmental management and disaster prevention.

At this point, it’s worth discussing how our company fits into the picture. At LANE, we’ve spent more than two decades focused on fertilizer machinery. With our engineering team, we design and manufacture complete production lines to meet each client’s requirements—from layout planning to on-site installation.

Because reliability matters just as much as equipment, we continue supporting our clients long after installation. Whether they need troubleshooting, maintenance, or upgrades, we stay involved to ensure every system operates at its best. Our products meet ISO 9001 and CE standards, and our expertise extends across fertilizer production lines, NPK systems, organic fertilizer equipment, and compound fertilizer machinery.

For anyone seeking guidance on building a Complete dap fertilizer production process, we take pride in delivering not only the machines but the experience, stability, and service that keep production running smoothly.

Modern fertilizer factories rely on advanced automation, but human expertise remains essential. Operators monitor batching flows, adjust mixer performance, supervise packaging output, and ensure safety across the line. When technology and trained workers work together, the Complete dap fertilizer production process becomes far more reliable and efficient.

As global agriculture evolves and wildfire prevention becomes more urgent, demand for high-quality DAP will continue to grow. Future production lines will likely feature smarter controls, predictive maintenance technologies, and increasingly efficient energy use.

With its dual environmental and agricultural benefits, DAP’s importance isn’t going away anytime soon—and optimizing the Complete dap fertilizer production process will remain essential for many industries.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.