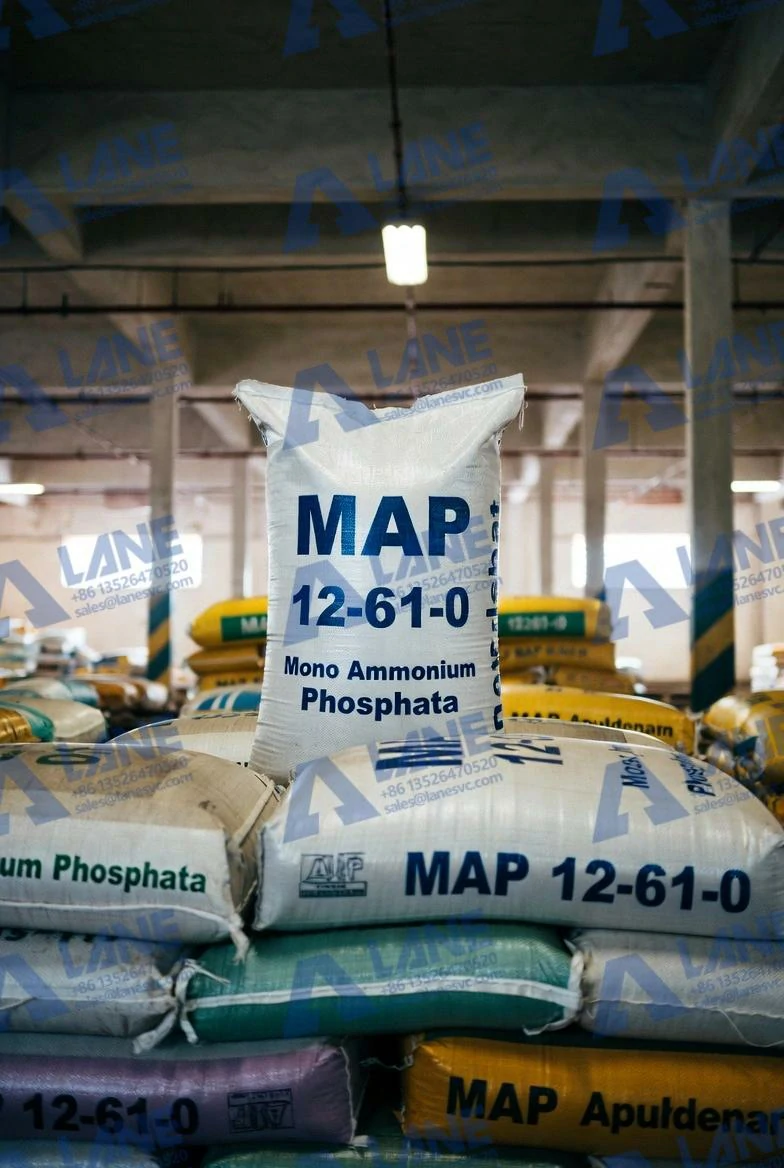

Producing high-quality MAP fertilizer has never been easier thanks to a customized phosphate fertilizer pilot plant with control system. Farmers and engineers now have the tools to test production processes, improve efficiency, and produce high-quality monoammonium phosphate in a controlled setting. This pilot plant is ideal for understanding raw material behavior, testing granulation processes, and ensuring consistent nutrient content before scaling up to full production. Additionally, it allows experimenting with different ammonium phosphate formulations without committing to full-scale production, which saves both time and cost.

Every MAP production line starts with proper handling of raw materials. A customized phosphate fertilizer pilot plant with control system includes storage hoppers, belt conveyors, and forklift feeders. These devices make it easy to store ammonium phosphate, phosphoric acid, and other additives safely. Accurate weighing and dosing systems ensure every batch has the correct nutrient ratio. Operators can also monitor material flow in real-time, which is especially useful when testing new formulas or adjusting recipes for different crop requirements. Proper raw material handling minimizes contamination and ensures the MAP fertilizer produced has uniform nutrient content.

MAP fertilizer production requires precise chemical reactions. In a pilot plant, neutralization reactors mix phosphoric acid with ammonium sources under controlled temperature and pressure. The customized phosphate fertilizer pilot plant with control system monitors pH, temperature, and reaction time automatically, reducing errors and ensuring consistency. Engineers can adjust parameters in real-time to see how the reaction affects granule formation and nutrient content. This level of control is especially valuable when working with varying raw material quality, ensuring the final MAP fertilizer meets desired standards.

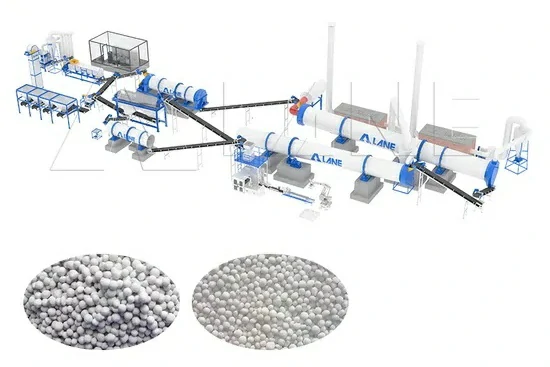

Once the chemical reaction is complete, the MAP slurry needs to be formed into granules. In pilot plants, double roller granulators are commonly used. These machines compress the fertilizer material between two rollers to create uniform, hard granules. A customized phosphate fertilizer pilot plant with control system allows operators to adjust roller pressure, feed rate, and moisture content, producing granules with consistent size and density.

Double roller granulators are particularly suitable for pilot plants because they are compact, easy to operate, and require minimal maintenance. Engineers can observe how granule size changes with pressure adjustments and test multiple formulas quickly. This ensures that even small-scale production tests yield reliable and high-quality MAP fertilizer, ideal for field trials or research purposes.

After granulation, MAP fertilizer contains high moisture and must be dried. Pilot plants often include fluidized bed dryers or rotary drum dryers to remove excess water efficiently. The customized phosphate fertilizer pilot plant with control system tracks temperature, airflow, and residence time to prevent overheating or uneven drying. Cooling systems then reduce granule temperature to avoid caking during storage. Controlled drying ensures the MAP fertilizer retains its nutrient quality and structural integrity. In addition, these systems help simulate large-scale production conditions, allowing engineers to fine-tune drying parameters before scaling up.

Not all granules meet size standards initially. Pilot plants use vibrating screeners or rotary screening machine to separate the desired granules from undersized or oversized particles. The rejected granules are returned to the double roller granulator. A customized phosphate fertilizer pilot plant with control system automates this process, maintaining consistent granule quality while reducing waste. This loop allows engineers to test multiple formulations efficiently and evaluate which parameters produce the most uniform MAP fertilizer.

Finally, the pilot plant includes conveyors and packaging machines for handling the finished MAP granules. A customized phosphate fertilizer pilot plant with control system enables precise weighing and filling of small bags or bulk containers. Automation reduces manual labor and ensures every batch is packaged consistently, making it easier to evaluate performance in field trials or demonstrations. Additionally, packaging can be adjusted to test different batch sizes or simulate commercial packaging conditions, providing valuable data for large-scale production planning.

Using a customized phosphate fertilizer pilot plant with control system offers many advantages. First, it allows testing of raw material variations without the cost of full-scale production. Second, the control system ensures precise monitoring and adjustments, so engineers can experiment safely. Third, it provides valuable data for designing large-scale MAP production lines. The ability to fine-tune granulation, drying, and screening parameters ensures the pilot plant produces high-quality, uniform MAP fertilizer every time.

At LANE, our company has over 20 years of experience in fertilizer machinery manufacturing. We have a professional engineering team that can design, manufacture, and install complete fertilizer production lines according to client needs. Our one-stop service covers installation, maintenance, troubleshooting, and upgrades, ensuring your production line operates efficiently. All our machines meet ISO9001 and CE international standards, giving customers reliable quality. We specialize in fertilizer production lines, NPK lines, organic fertilizer machines, and compound fertilizer equipment, offering comprehensive and professional solutions.

A customized phosphate fertilizer pilot plant with control system is especially useful for research institutions, small-scale production, or testing new MAP formulations. Greenhouse operators, for instance, can produce small batches to trial nutrient effects before committing to large-scale planting. It’s also ideal for training operators to understand equipment operation, process flow, and quality control. Engineers can run multiple simulations on granulation speed, drying time, and cooling conditions, making this pilot plant a versatile tool for optimization.

Investing in a customized phosphate fertilizer pilot plant with control system allows farmers and engineers to test, optimize, and perfect MAP fertilizer production safely and efficiently. From raw material handling to double roller granulation, drying, screening, and packaging, pilot plants provide full control over every step. With the support of experienced companies like LANE, producing high-quality MAP fertilizer is simpler, safer, and more reliable.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.