Have you ever wondered how those tiny, uniform fertilizer granules actually get made? If you’re in the world of farming or agribusiness, you know that the quality of your pellets can make or break a harvest. Recently, there has been a lot of buzz around the double roller granulator for phosphate fertilizer, and for good reason! It’s quickly becoming the go-to choice for people who want efficiency without the massive energy bills.

In this article, we’re going to chat about what makes this equipment so special, why the “dry granulation” method is winning hearts, and how our team at LANE can help you set up a system that works like a charm.

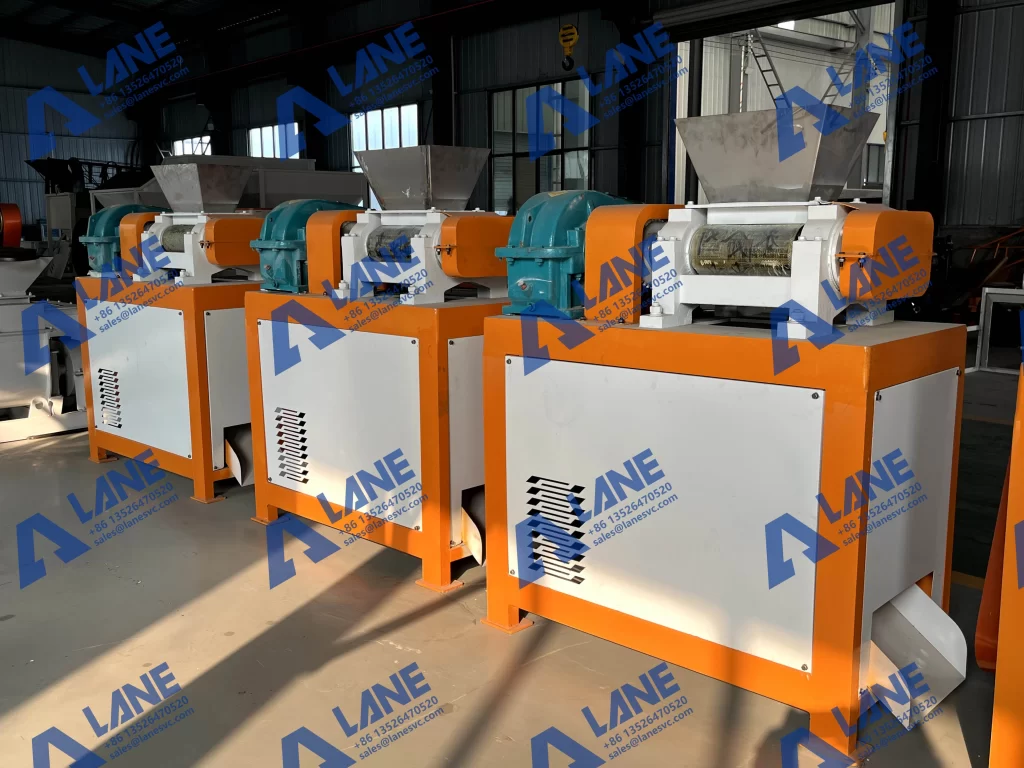

To put it simply, a double roller granulator for phosphate fertilizer is a machine that uses high pressure to squeeze powdered materials into solid shapes. Imagine pressing two coins together with a piece of clay in between—that’s the basic idea, but on a much larger, industrial scale.

What sets the double roller granulator for phosphate fertilizer apart from older methods (like steam or spray granulation) is that it doesn’t require you to get the material wet. Because the process is “dry,” you don’t have to spend a fortune on massive drying ovens. For anyone trying to keep their overhead costs low, this is a huge win.

Phosphate is vital for root development and blooming. However, handling it can be tricky. Using a double roller granulator for phosphate fertilizer ensures that the chemical properties of the phosphate remain stable. Since there’s no high heat or excessive moisture involved in the squeezing process, the nutrients stay packed inside the granule, ready to be released into the soil when the farmer needs them most.

Lower Energy Costs: No drying means no huge fuel bills.

Compact Space: These machines are relatively small compared to giant rotary drums.

High Success Rate: The double roller granulator for phosphate fertilizer produces very little “waste” dust. Most of what goes in comes out as a perfect pellet.

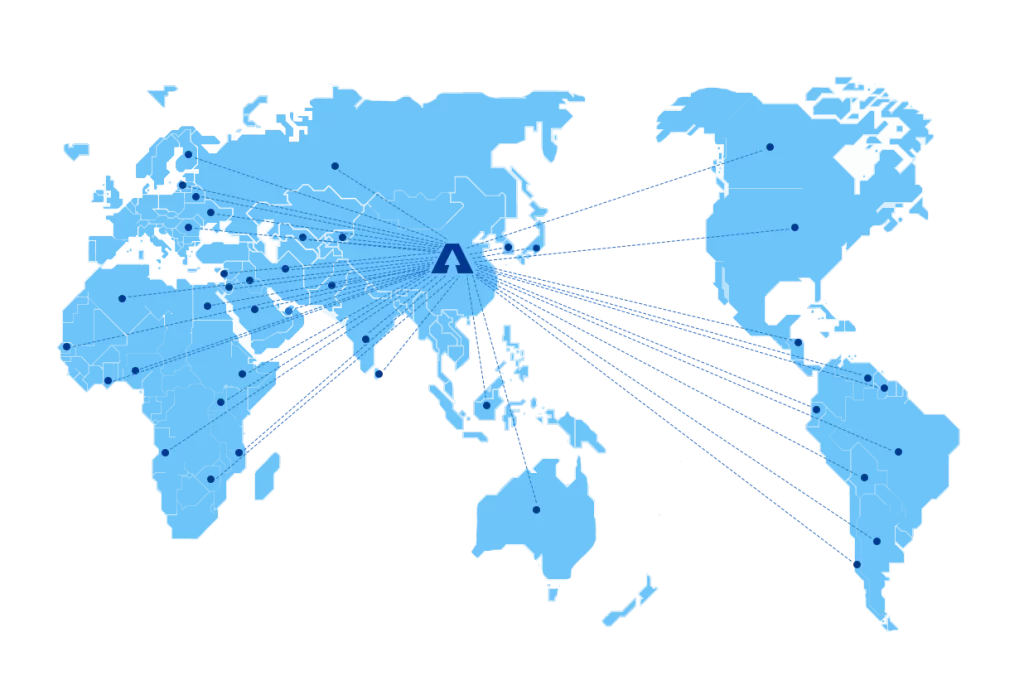

At LANE, we aren’t just selling machines; we’re sharing over 20 years of passion for the fertilizer industry. We’ve spent two decades in China’s fertilizer machinery manufacturing sector, learning exactly what works and what doesn’t. When you choose a double roller granulator for phosphate fertilizer from us, you’re getting twenty years of “trial and error” distilled into one powerful piece of equipment.

We know that no two farms or factories are the same. That’s why we have a professional engineering team ready to roll up their sleeves. Want a specific layout? Need a double roller granulator for phosphate fertilizer that fits into a tight corner of your existing warehouse? We’ve got you covered. We don’t just ship a box to your door; we design, manufacture, and install the entire fertilizer production line for you.

We take quality seriously—and we have the paperwork to prove it. Our products meet ISO9001 and CE international quality standards. When you see our double roller granulator for phosphate fertilizer running on your floor, you can rest easy knowing it’s built to last and meets the highest global benchmarks for safety and performance.

One of the things our clients love most about working with us is our “all-in-one” approach. We realize that buying a double roller granulator for phosphate fertilizer is a big investment. You don’t want to be left hanging once the machine arrives.

Installation: Our team shows up to make sure everything is bolted down and wired correctly.

Maintenance: We provide clear guides and support to keep things running smoothly.

Troubleshooting: If something sounds “off,” we’re just a call away.

Upgrades: As your business grows, we help you scale your production line to keep up with demand.

Whether you are looking for NPK production lines, organic fertilizer equipment, or a specialized double roller granulator for phosphate fertilizer, we provide the full spectrum of services to ensure your line stays stable and efficient.

In today’s world, everyone is looking for “green” solutions. Because the double roller granulator for phosphate fertilizer uses a room-temperature process, it’s much more environmentally friendly than traditional methods. There’s no smoke from drying furnaces and less water waste. It’s a great way to show your customers that you care about the planet while also producing a premium product.

The granules produced by a double roller granulator for phosphate fertilizer are also very easy to store. They don’t clump together as easily as wet-granulated pellets, meaning they stay fresh in the bag for much longer.

Choosing the right equipment is a huge decision. The double roller granulator for phosphate fertilizer offers a perfect balance of cost-efficiency, nutrient preservation, and ease of use. It’s the “smart” choice for the modern age of agriculture.

At LANE, we’ve spent 20 years perfecting these systems. We’ve seen the industry change, and we’ve evolved right along with it. From our professional engineering designs to our dedicated after-sales support, we are here to make sure your investment in a double roller granulator for phosphate fertilizer pays off for years to come.

So, are you ready to take your fertilizer production to the next level? We’d love to help you design a production line that fits your dreams.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.