Setting up a MAP fertilizer plant with 8t/h capacity in Brazil is a smart move. MAP, or monoammonium phosphate, is a popular fertilizer. It provides nitrogen and phosphorus to crops. In Brazil, farms need this for soybeans and corn. A plant with 8 tons per hour output can meet local needs. This size fits small to medium operations. It helps reduce import costs.

The process starts with raw materials like ammonia and phosphoric acid. These turn into granules. Equipment handles mixing, forming, and packing. We will look at what machines you need. Also, how they connect in the line. Plus, a quick view of Brazil’s market. For a MAP fertilizer plant with 8t/h capacity in Brazil, planning is key. You must think about space, power, and rules.

To build a MAP fertilizer plant with 8t/h capacity in Brazil, you need specific machines. These handle each step of making MAP granules. First, a batching system. It measures raw materials like ammonia, phosphoric acid, and fillers. Accurate amounts ensure good quality. Use electronic scales for precision.

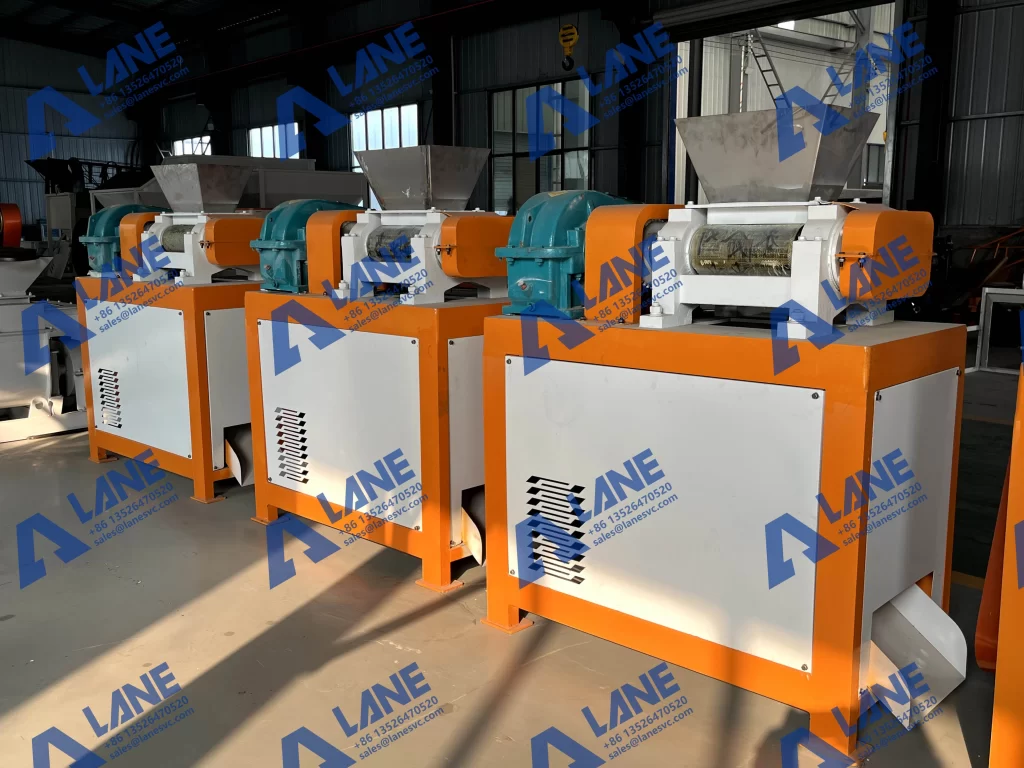

Next, a double shaft mixer. This blends the materials. In MAP production, ammonia reacts with phosphoric acid. The mixer stirs them well. It forms a slurry. For an 8t/h plant, choose a horizontal mixer. It handles large volumes.

Then, a granulator. This turns the material into granules. A double roller granulator works well for dry granulation. It squeezes the dry powder mix between two counter-rotating rollers. High pressure forms the powder into sheets or strips first. Then, a crusher breaks them into small, uniform granules, about 2-4mm in size. No need to add water or binders in most cases. The granules are hard and dense.

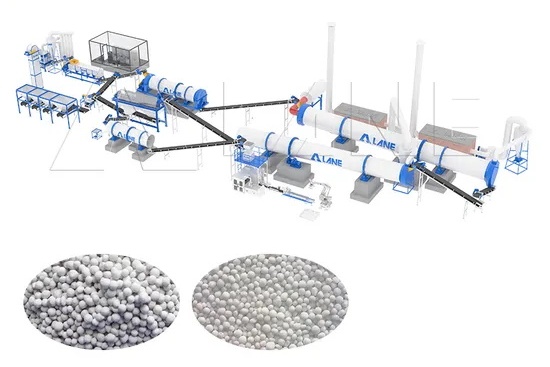

After granulation, a dryer. It removes water from wet granules. Use a rotary dryer with hot air. This makes granules hard and dry. For 8t/h capacity, it needs to process fast.

A cooler follows the dryer. It lowers the temperature. Hot granules can stick together. A rotary cooler uses air to cool them. This step prevents clumping.

Then, a rotary screening machine. It sorts granules by size. Too small or big ones go back to granulate again. A vibrating screen does this job.

Optional is a coating machine. It adds a layer to granules. This stops moisture absorption. Use a rotary coater for even coverage.

Finally, a packing machine. It fills bags with finished MAP. Automatic ones weigh and seal. For Brazil, choose dust-proof models.

In a MAP fertilizer plant with 8t/h capacity in Brazil, these machines form the core. You may add conveyors to move materials between them. Belt conveyors are common. They save labor.

In a MAP fertilizer plant with 8t/h capacity in Brazil, equipment links in a flow. It starts at the batching system. Raw materials enter here. Scales measure exact amounts. Then, a conveyor takes them to the mixer.

In the mixer, chemicals react. Ammonia and acid form MAP slurry. Heat builds up, so control it. The slurry goes to the granulator via pumps.

The granulator shapes the slurry. It spins and adds steam or water. Granules form and exit to the dryer.

The dryer uses fuel like gas to heat air. Granules tumble inside. Moisture evaporates. Hot granules move to the cooler.

Cooler fans blow air. Temperature drops to room level. Cooled granules go to the screen.

The screen shakes to separate sizes. Good ones proceed. Others recycle to the granulator.

If coating, granules enter the coater. It sprays anti-caking agents. Then, to packing.

Packing machine fills 25kg or 50kg bags. Seals them for storage.

This synergy keeps the line running at 8t/h. Sensors monitor speed. If one part slows, others adjust. In Brazil, where humidity is high, dryers and coolers are vital. They prevent sticky granules. The whole system uses PLC controls for automation. This reduces errors. Workers oversee, but machines do most work. For a MAP fertilizer plant with 8t/h capacity in Brazil, this flow ensures steady output.

Brazil’s fertilizer market is huge. It is a top agriculture nation. Crops like soybeans, corn, and sugarcane need nutrients. MAP is key for phosphorus. Demand grows each year.

Soil in Brazil lacks phosphorus. MAP fixes that. It boosts yields. For soybeans, main export, MAP is essential.

Challenges include high energy costs. But solar power helps. Also, rules on environment. Plants must treat waste.

Opportunities are big. Exports to neighbors possible. With 8t/h capacity, a plant makes 50,000 tons a year if running full. This meets local needs. Farmers prefer local supply. It is faster and cheaper.

In short, a MAP fertilizer plant with 8t/h capacity in Brazil fits the market well. Demand is strong. Local production saves money.

At LANE, we specialize in manufacturing fertilizer machinery in China for more than 20 years. Our professional engineering team designs and builds equipment for your needs. We handle whole production lines, like for MAP fertilizer plant with 8t/h capacity in Brazil.

As a trusted supplier, we provide full services. From installation to after-sales support. We help with maintenance and upgrades. This keeps your line running smooth.

Our quality meets ISO9001 and CE standards. We excel in compound fertilizer machines, including NPK and organic lines.

Choose us at LANE for reliable solutions. We ensure your MAP fertilizer plant with 8t/h capacity in Brazil operates at its best.

Building a MAP fertilizer plant with 8t/h capacity in Brazil needs right equipment and planning. From batching to packing, machines work as a team. Brazil’s market offers good chances. With growing demand, such a plant can thrive. Think about costs and location. Start small, grow big. This setup boosts farm output. It supports Brazil’s agriculture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.