Monoammonium phosphate (MAP) is one of the most widely used phosphate fertilizers in global agriculture. Known for its high phosphorus content, excellent solubility, and compatibility with other fertilizers, MAP continues to play an essential role in crop nutrition. As global demand for efficient phosphate fertilizers grows, more investors and fertilizer manufacturers are planning to build or upgrade their MAP fertilizer processing plant to strengthen market competitiveness.

This comprehensive guide explains the complete MAP production process, the equipment required, plant layout considerations, investment advantages, and key success factors. Whether you plan to set up a new MAP fertilizer processing plant or optimize an existing one, this article will help you understand the technology and business potential behind MAP production.

What Is a MAP Fertilizer Processing Plant?

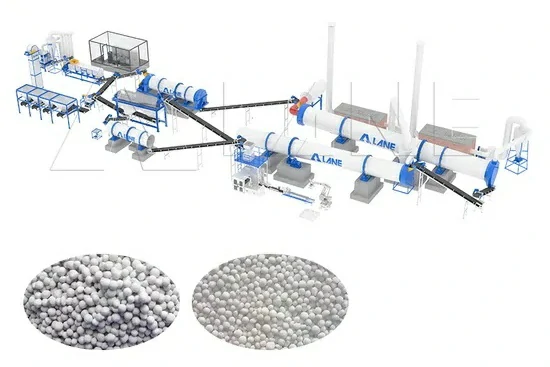

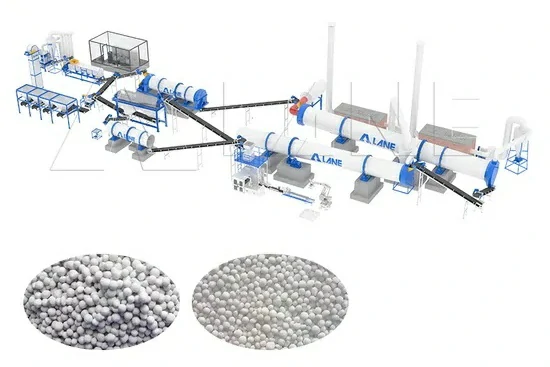

A MAP fertilizer processing plant is an integrated industrial facility that transforms phosphoric acid and ammonia into granular monoammonium phosphate. The process typically includes ammoniation reaction, granulation, drying, cooling, screening, packaging, and dust control.

The purpose of the plant is to:

Produce high-quality MAP granules with stable nutrient composition (11-12% Nitrogen and 50-52% Pâ‚‚Oâ‚…)

Ensure efficient use of phosphoric acid and ammonia

Deliver market-ready fertilizer with strong granules suitable for transportation and blending

Support downstream NPK compound fertilizer production

MAP fertilizer is widely used in:

Grain, vegetable, and fruit crop production

Custom-made NPK formulations

Drip irrigation and precision fertilization systems

Fertilizer blending (BB fertilizer)

A well-designed MAP fertilizer processing plant ensures consistent quality, lower production cost, and long-term operational reliability.

Raw Materials Required in a MAP Fertilizer Processing Plant

A modern MAP fertilizer processing plant relies on a precise combination of chemical raw materials and auxiliary additives to ensure stable reactions, efficient granulation, and high-quality final products. Although the core chemistry of MAP (Monoammonium Phosphate) is straightforward, the reliability of the plant’s output depends heavily on material purity, concentration, and consistency. Below is a clear overview of the essential raw materials required for continuous MAP production.

1.Phosphoric Acid: The Primary Source of Phosphorus

Phosphoric acid is the foundational raw material in any MAP fertilizer processing plant, providing the phosphorus content that defines MAP fertilizer. The industrial grade phosphoric acid with a Pâ‚‚Oâ‚… content ranging from 40% to 54% is usually used. Phosphoric acid with a higher purity can lead to more stable reactions, fewer impurities and better particle strength. The stable acid concentration can also ensure precise pH control during the ammoniation process, which is crucial for generating monoammonium phosphate rather than diammonium phosphate.

2.Ammonia: The Key Nitrogen Source

Anhydrous ammonia is the nitrogen source required for the production of monoammonium phosphate (MAP). It reacts with phosphoric acid in a controlled environment to form a phosphate monammonium slurry. The quality of ammonia – particularly its vapor pressure and feed stability – directly affects the heat release, moisture content, and reaction efficiency. Appropriate ammonia storage, vaporization, and feed systems are crucial for the safe and stable operation of a phosphate monoammonium fertilizer plant.

3.Process Water: Supporting Reaction and Conditioning

Although MAP is not a water-intensive product, process water plays several important roles, including:

Diluting phosphoric acid when necessary

Balancing slurry viscosity during ammoniation

Supporting granulation when the slurry becomes too dry

Cleaning pipelines and reaction equipment

Clean water quality ensures fewer impurities and avoids scaling issues in the reactor and granulator.

4.Recycled Fines and Crushed Oversize Granules

A MAP fertilizer processing plant operates most efficiently with a well-designed recycle loop. Undersized granules collected from screening and crushed oversized particles serve as seed material inside the granulator. These recycled fines help:

Improve granulation efficiency

Increase particle uniformity

Reduce the consumption of fresh raw materials

Stabilize the granule formation process

A strong recycle stream is one of the defining advantages of continuous MAP granulation systems.

Core Production Flow of a MAP Fertilizer Processing Plant

1.Ammoniation Reaction: Creating the MAP Slurry

The production process in a MAP fertilizer processing plant begins with the ammoniation reaction, where phosphoric acid and ammonia are accurately metered and fed into a controlled reactor or directly into the granulator. The goal is to achieve the correct N:P ratio and maintain optimal reaction temperature. A semi-fluid MAP slurry is produced, serving as the starting point for granulation.

2.Granulation: Forming Stable MAP Particles

The slurry then moves into the granulation section, the core of any MAP fertilizer processing plant. Inside a double roller granulator or disc granulator, the slurry mixes with recycled fines. Through rolling, layering, and controlled reaction completion, the material gradually forms uniform MAP granules. Additional ammonia or acid can be sprayed to stabilize chemical balance and support particle growth.

3.Drying: Reducing Moisture for Product Stability

Fresh MAP granules contain excess moisture, so they enter a rotary drum dryer where hot air removes water and solidifies the particles. Proper drying temperature and retention time are crucial—overdrying causes fragile granules while underdrying increases caking risk. The drying stage ensures the granules are strong and ready for cooling.

4.Cooling: Strengthening and Stabilizing Granules

After drying, granules are directed into a cooler. Ambient air flow quickly lowers their temperature, preventing moisture rebound and improving hardness. Effective cooling is essential for storage stability, especially in humid climates, making it a key step in a modern MAP fertilizer processing plant.

5.Screening: Ensuring Consistent Particle Size

The cooled granules enter a multi-layer rotary or vibrating screen. Here, MAP particles are classified into qualified product, oversized granules, and undersized fines. Oversize granules are crushed and recycled, while fines re-enter the granulation stage. This closed-loop design ensures high yield and consistent granule size distribution.

6.Coating (Optional): Improving Anti-Caking Performance

Before packaging, some plants apply a thin coating layer to MAP granules. Anti-caking agents or dust suppressants improve storage performance and prevent clumping during long-distance transport. Though optional, this step greatly enhances the market competitiveness of MAP products.

7.Packing: Finalizing the Finished MAP Product

The last stage in the MAP fertilizer processing plant is packaging. Automated packing machines fill MAP granules into 25 kg, 50 kg, or 1-ton jumbo bags with precise weight control. Once sealed, the product is ready for warehousing and distribution, completing the transformation from raw materials to high-value fertilizer.

Why MAP Production Is a Strong Investment

A MAP fertilizer processing plant offers significant advantages for fertilizer producers, investors, and agricultural supply companies. With stable demand, scalable production capacity, and mature technology, MAP remains one of the most profitable and reliable phosphate fertilizers on the global market.

Whether you aim to enter the fertilizer industry, expand production, or supply MAP for NPK blending, building a MAP fertilizer processing plant is a strategic and future-proof investment.

If you need help designing a plant, selecting equipment, or estimating investment cost, feel free to let me know—I can help you build the complete project step by step.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.