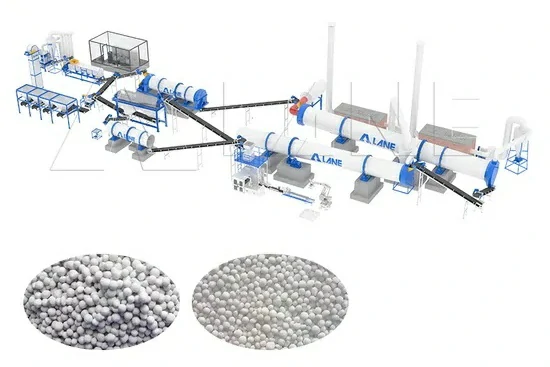

Producing Monoammonium Phosphate (MAP) fertilizer requires a well-coordinated set of machines that work together smoothly from the first stage of material handling to the final packaging process. This is why choosing reliable MAP production equipment is essential for stable output, consistent granule quality, and long-term efficiency. Modern fertilizer factories depend on automated systems, smart controls, and specialized machinery to ensure that the final product is uniform and nutrient-balanced, making MAP fertilizer easier for crops to absorb and better suited for large-scale agricultural use.

With farmers increasingly demanding fertilizers that are more efficient and environmentally responsible, manufacturers must rely on production lines that reduce waste, minimize energy use, and protect nutrient content through every step. Below is a clear and friendly introduction to all major machines commonly used in MAP production and how they contribute to quality and performance.

The first stage of MAP production involves accurate weighing of raw materials, and this is handled by dynamic batching scales. These automated scales measure phosphate rock, ammonia, fillers, and additives with high precision. Their built-in load cells and smart controllers ensure that each ingredient is fed at the right speed and proportion.

In daily operation, the system continuously adjusts itself to maintain accuracy even when material flow changes. This stability helps reduce waste and ensures the chemical balance of MAP fertilizer remains consistent. Because the data is recorded in real time, operators can track ingredient usage and quickly detect deviations. As part of modern MAP production equipment, batching scales play an essential role in keeping production stable and ingredients properly blended from the very beginning.

After materials are weighed, they are transferred to the vertical crusher, a machine designed to crush and grind raw phosphate rock and other additives into a fine, uniform powder. The machine’s vertical structure uses gravity to feed materials downward while the internal blades rotate at high speed, breaking down particles efficiently.

This grinding step ensures that every particle is small enough to react properly during granulation. A uniform powder also improves mixing results and increases granule strength later in the process. Operators can adjust rotor speed, blade angle, and screen size depending on the hardness of the material. With proper setup, this machine helps the entire set of MAP production equipment operate more smoothly and consistently.

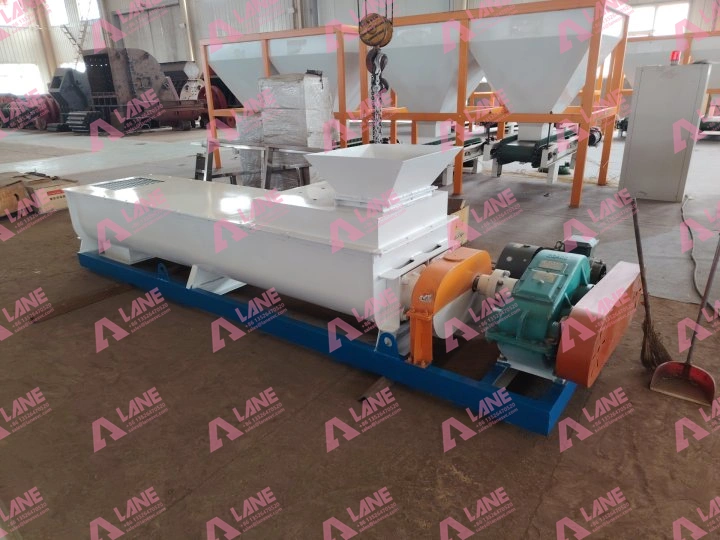

The powder then enters the twin-shaft mixer, where two horizontal shafts rotate in opposite directions. Attached paddles sweep the material repeatedly, ensuring that all ingredients blend uniformly. Good mixing is crucial because the nutrient balance in each MAP granule depends on even distribution.

This mixer handles large volumes and operates with minimal resistance, which helps save energy. Inside the chamber, the movement of the paddles creates a fluidized mixing effect that reduces dead spots and prevents material buildup. This steady and reliable mixing process helps maintain product quality and improves the performance of all downstream MAP production equipment in the production line.

One of the most important machines in MAP manufacturing is the two-in-one granulator, which handles both mixing and granulating duties in a single structure. This dual-function design saves space and energy while producing rounded granules with good strength and uniform shape.

During operation, the raw powder enters the granulation chamber where high-speed mechanical forces combine with moisture and pressure to form granules. Operators can adjust the moisture level, rotation speed, and angle to achieve different granule sizes. A well-tuned granulator provides consistent particle size, improves fertilizer dissolving behavior, and reduces dust. As a core element of MAP production equipment, it directly shapes the final fertilizer quality.

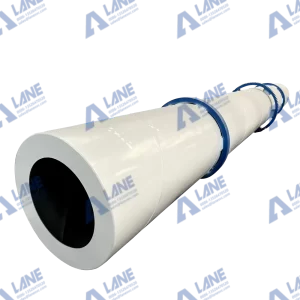

When granules leave the granulator, they still contain excess moisture. The dryer reduces this moisture to safe storage levels. Warm air passes through the tumbling granules, carrying away moisture without overheating or damaging the product.

Temperature control is critical. If the air is too hot, granules may crack; too cold, and they will not dry properly. Modern dryers use efficient airflow systems, heat recovery designs, and automated temperature adjustments, helping manufacturers reduce energy costs. A reliable dryer supports the overall performance of MAP production equipment by ensuring that granules maintain strength and stability during storage and transport.

After drying, granules enter the cooler. This step might seem simple, but it is extremely important for maintaining granule quality. Hot granules are fragile, and cooling them quickly helps prevent breakage and moisture absorption.

Coolers use large airflow systems that pull ambient air through the granules as they move slowly through the chamber. This reduces granule temperature and strengthens the outer surface. The cooler also helps control dust and ensures that the granules leaving the machine are stable and ready for screening. Smooth cooling improves the operation of the remaining MAP production equipment in the line.

Once properly cooled, the granules move into the drum screening machine. This rotating cylinder separates granules by size: fine powder falls through small holes, properly sized granules pass through smoothly, and oversized pieces move to the end for secondary processing.

Consistent granule size is essential for fertilizer application because it ensures even spreading in the field and predictable nutrient release. A good screening machine helps maintain product standardization and reduces waste. When used with other MAP production equipment, drum screening helps ensure the final product meets customer expectations.

Some MAP products require extra protection, and the coating machine applies a thin layer of anti-caking or anti-dust material. This improves storage performance, prevents clumping, and helps granules flow smoothly during transportation and loading.

The machine sprays a controlled amount of coating liquid while the drum rotates, ensuring that every granule receives uniform coverage. This step also improves the overall appearance of the fertilizer. Coating technology is increasingly important in modern MAP production equipment, especially for markets that require high-quality packaging and long-distance transport.

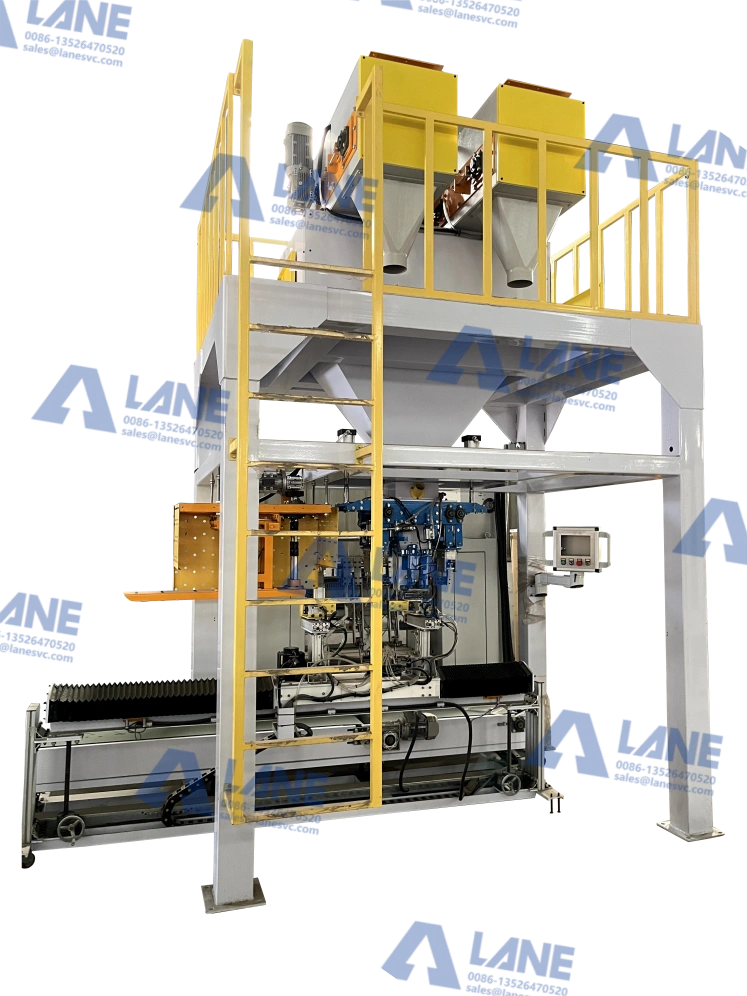

The last stage of the MAP production line is the packaging machine, which fills, weighs, seals, and stacks finished fertilizer bags. With automated control and sensors, the machine ensures that each bag meets the correct weight specifications.

Packaging efficiency is crucial for large factories because it directly affects shipment speed and labor costs. Modern packaging machines integrate conveyor belts, bag-clamping devices, and digital scales to deliver fast and accurate packaging. As the final component of MAP production equipment, this machine ensures that the finished fertilizer is ready for distribution.

At LANE, we have more than 20 years of experience as a fertilizer machinery manufacturer in China. Our company has a skilled engineering team that designs, manufactures, and installs complete MAP production lines tailored to each customer’s needs. We take pride in delivering full support—from installation to long-term maintenance, troubleshooting, upgrades, and operator training.

All our equipment follows ISO 9001 and CE quality standards, ensuring durability, safety, and stable performance. Whether you need a MAP line, an NPK line, an organic fertilizer machine, or a complete compound fertilizer plant, we provide solutions that improve efficiency and help customers expand their production with confidence. With our experience and commitment, we make sure your MAP production equipment continues running smoothly year after year.

A complete set of MAP production equipment plays a crucial role in producing high-quality fertilizer that is easy to store, transport, and apply. Each machine—from the batching scales to the final packaging unit—contributes to product consistency and long-term reliability. By choosing professionally designed equipment and working with experienced manufacturers like LANE, fertilizer producers can achieve stable output, reduced waste, and improved nutrient efficiency. Reliable machinery is the foundation of successful MAP fertilizer manufacturing.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.