The phosphate fertilizer dryer and cooler are two of the most critical machines in any phosphate fertilizer production line. Together, they determine the final moisture, temperature, and physical strength of the fertilizer granules, ensuring the productβÄôs stability, quality, and market value.

In modern fertilizer manufacturing, proper drying and cooling technology is not just about removing moisture βÄî itβÄôs about energy efficiency, product consistency, and environmental protection.

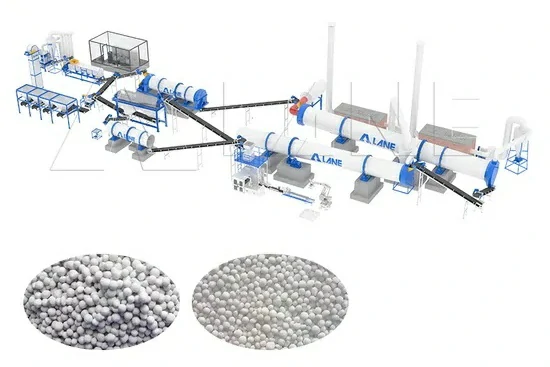

With over a decade of manufacturing experience, LANE provides advanced phosphate fertilizer dryers and coolers designed to meet the demanding needs of phosphate, DAP, MAP, and NPK compound fertilizer production lines worldwide.

What Is a Phosphate Fertilizer Dryer and Cooler?

A phosphate fertilizer dryer and cooler system is a set of two continuous process machines used after granulation.

After the granules are formed in a granulator, they typically have a moisture content of 8βÄ™12% and a temperature of 70βÄ™100¬ΑC. Such granules are not suitable for packaging or storage. The dryer removes excess moisture, while the cooler reduces the temperature to near ambient levels.

Functions:

Dryer: Evaporates water to reduce granule moisture below 2%.

Cooler: Cools granules to room temperature (usually below 40¬ΑC) for safe storage and coating.

This two-step process is essential for maintaining granule hardness, preventing caking, and ensuring a long shelf life.

Why Drying and Cooling Are Essential in Phosphate Fertilizer Production

The granulation process in phosphate fertilizer production involves water and chemical reactions that generate heat and moisture. If not properly managed, these factors can lead to:

Sticky or soft granules

Clumping during storage

Nutrient loss or decomposition

High energy waste in downstream handling

By using a phosphate fertilizer dryer and cooler, manufacturers can:

Stabilize the productβÄôs chemical structure.

Improve granule appearance and hardness.

Increase packaging and transportation efficiency.

Maintain consistent product quality.

LANEβÄôs phosphate fertilizer dryer and cooler systems are optimized for high thermal efficiency and low dust emissions, meeting international environmental standards.

Working Principle of a Phosphate Fertilizer Dryer

The phosphate fertilizer dryer typically uses a rotary drum structure, one of the most efficient and widely used designs in the fertilizer industry.

3.1 Process Flow

Material Feeding: Moist phosphate granules from the granulator enter the rotary drum dryer through a feeding chute.

Hot Air Supply: Hot air, generated from a burner (gas, coal, or biomass), is introduced into the drum either co-currently or counter-currently with the material flow.

Heat Exchange and Evaporation: As the drum rotates, internal lifting plates continuously lift and scatter the granules through the hot air stream. This increases contact area and accelerates moisture evaporation.

Exhaust System: Moist air exits through a dust collection system such as a cyclone dust collector or bag filter, ensuring environmental safety.

Discharge: Dried granules are discharged with final moisture content typically less than 2%, ready for the cooling process.

3.2 Technical Features of LANE Rotary Dryer

High Drying Efficiency: Heat utilization rate up to 85%.

Uniform Drying: Multi-layer lifting plates ensure even heat exposure.

Energy Saving: Optional waste heat recovery and frequency control system.

Corrosion Resistance: Drum material can be customized in stainless steel or carbon steel with anti-corrosion coating.

Automation: Integrated temperature and moisture sensors for precise control.

Case Study: Boosting Efficiency with a 15 t/h Phosphate Fertilizer Dryer and Cooler System in South America

In 2024, LANE successfully implemented a 15 tons-per-hour phosphate fertilizer production line for a large agricultural input supplier based in South America. The clientβÄôs goal was clear βÄî to modernize its existing line, reduce energy consumption, and produce phosphate-based fertilizers that met both domestic and export standards.

Before working with LANE, the company relied on an outdated drying system that caused inconsistent granule moisture and frequent blockages in the cooling section. As a result, product uniformity was poor, and energy costs were steadily increasing. To address these challenges, the company decided to upgrade to a LANE phosphate fertilizer dryer and cooler system, known for its high thermal efficiency and low environmental impact.

After a detailed on-site survey and raw material analysis, LANE engineers designed a customized rotary dryer and rotary cooler combination, integrated seamlessly into the existing granulation line.

System Configuration Included:

Rotary Drum Dryer (Ο‰2800 Ο½ 12,000 mm)

Rotary Drum Cooler (Ο‰2800 Ο½ 10,000 mm)

Gas-fired hot air furnace

Cyclone dust collector and bag filter unit

Automatic temperature and moisture control system

LANEβÄôs design prioritized energy recovery and material flow stability. The dryer and cooler were connected via a sealed transfer conveyor to prevent heat loss and minimize dust escape.

After installation and commissioning, the phosphate fertilizer dryer and cooler operated continuously for 72 hours under full load conditions. The system achieved exceptional performance metrics:

| Parameter | Before Upgrade | After LANE Upgrade |

| Production Capacity | 10 t/h | 15 t/h |

| Final Moisture | 4.5% | βâΛ 1.8% |

| Granule Temperature (After Cooling) | 58¬ΑC | βâΛ 38¬ΑC |

| Fuel Consumption | 100% baseline | βÄ™22% |

| Dust Emission | High | <50 mg/Nm³ (ISO Standard) |

These results exceeded the clientβÄôs expectations, leading to smoother downstream screening and packaging processes and a noticeable reduction in product loss due to caking.

The plantβÄôs production manager noted:

βÄ€The new phosphate fertilizer dryer and cooler from LANE has completely changed our efficiency. The moisture control is precise, and the energy savings are beyond what we expected. Our product now meets international granule quality standards.βÄù

LANE also provided operator training, maintenance guidance, and a remote monitoring system, allowing the clientβÄôs engineering team to track drying performance in real time.

Future Trends in Phosphate Fertilizer Drying and Cooling

As sustainability becomes a key goal in global fertilizer production, phosphate fertilizer dryer and cooler technology is evolving rapidly.

Emerging trends include:

Heat Recovery Systems: Capturing exhaust heat to preheat incoming air.

AI-Controlled Operation: Real-time adjustment of drying parameters for precision control.

Hybrid Energy Sources: Integration of solar or waste heat with gas burners.

Low-Dust Rotary Designs: Improved sealing to reduce emissions.

LANE is at the forefront of these innovations, continually developing smarter, greener drying and cooling equipment to support eco-friendly fertilizer plants worldwide.

Frequently Asked Questions (FAQ)

Q1: What is the ideal moisture content after drying?

Typically, the final moisture content for phosphate fertilizer granules should be below 2%.

Q2: Can the dryer and cooler work continuously?

Yes. LANEβÄôs phosphate fertilizer dryer and cooler are designed for 24-hour continuous operation with minimal maintenance downtime.

Q3: What type of fuel can be used?

Common fuels include coal, natural gas, diesel oil, or biomass βÄî depending on local availability.

Q4: How long is the drying time?

Usually 10βÄ™20 minutes, depending on drum size, temperature, and material moisture.

Q5: WhatβÄôs the service life of the equipment?

With proper maintenance, the drum and core components can last 10βÄ™15 years or more.

Conclusion

The phosphate fertilizer dryer and cooler are indispensable for achieving high-quality, durable, and market-ready fertilizer granules. By precisely controlling moisture and temperature, these machines ensure your production line runs efficiently, economically, and safely.

With LANEβÄôs proven technology, customized engineering solutions, and full after-sales service, fertilizer manufacturers worldwide trust our drying and cooling systems for their reliability and superior performance.

Whether youβÄôre upgrading an existing line or building a new phosphate fertilizer plant, LANEβÄôs phosphate fertilizer dryer and cooler solutions will keep your production stable, efficient, and environmentally compliant.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.