In modern agriculture, fertilizer is closely connected to food production and daily life. Behind every bag of fertilizer, there is a careful manufacturing process. One very important part of this process is the phosphate fertilizer dryer and cooler system. This equipment helps fertilizer move from a wet and hot state to a dry, stable, and ready-to-use product that farmers can trust.

Fertilizer factories often work nonstop. Raw materials come in with high moisture and heat, and they must be handled carefully. If this step is not done well, the final product quality will drop. That is why drying and cooling are not small details, but key steps in the whole production line.

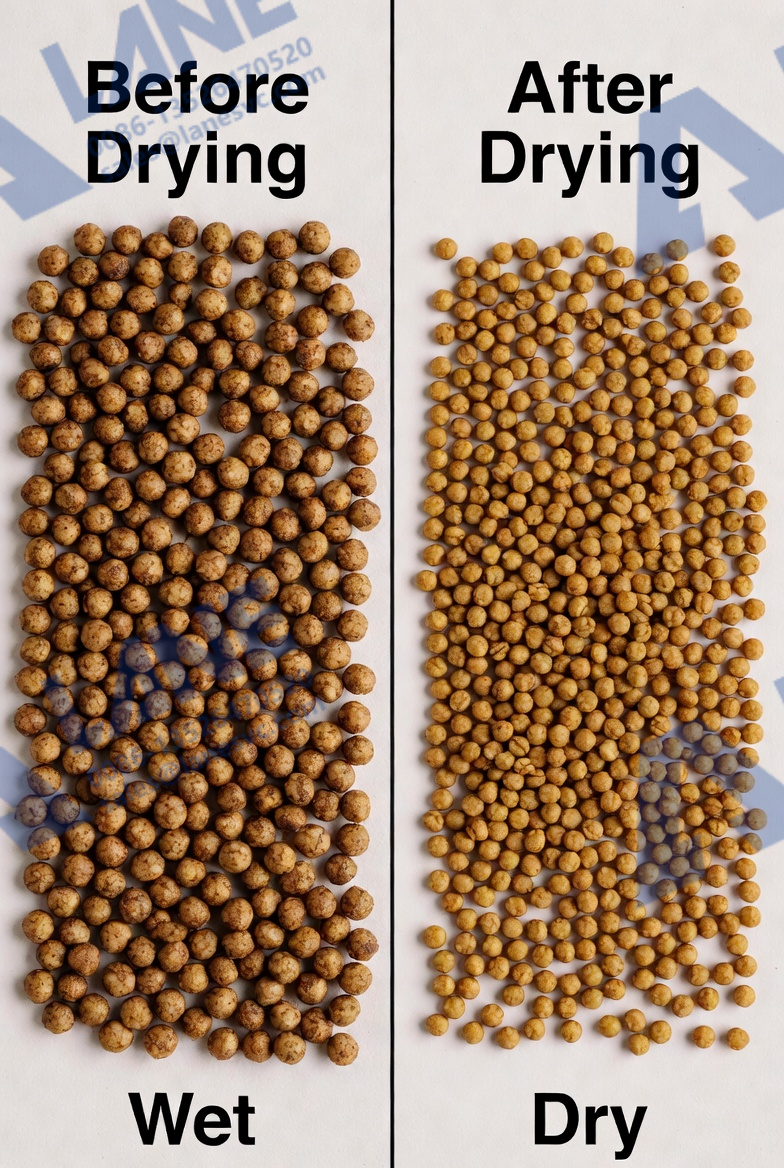

When phosphate fertilizer is first formed, it usually contains water from mixing and chemical reactions. Wet fertilizer is heavy, sticky, and hard to manage. It can easily break, clump together, or grow mold during storage. Drying helps solve all these problems.

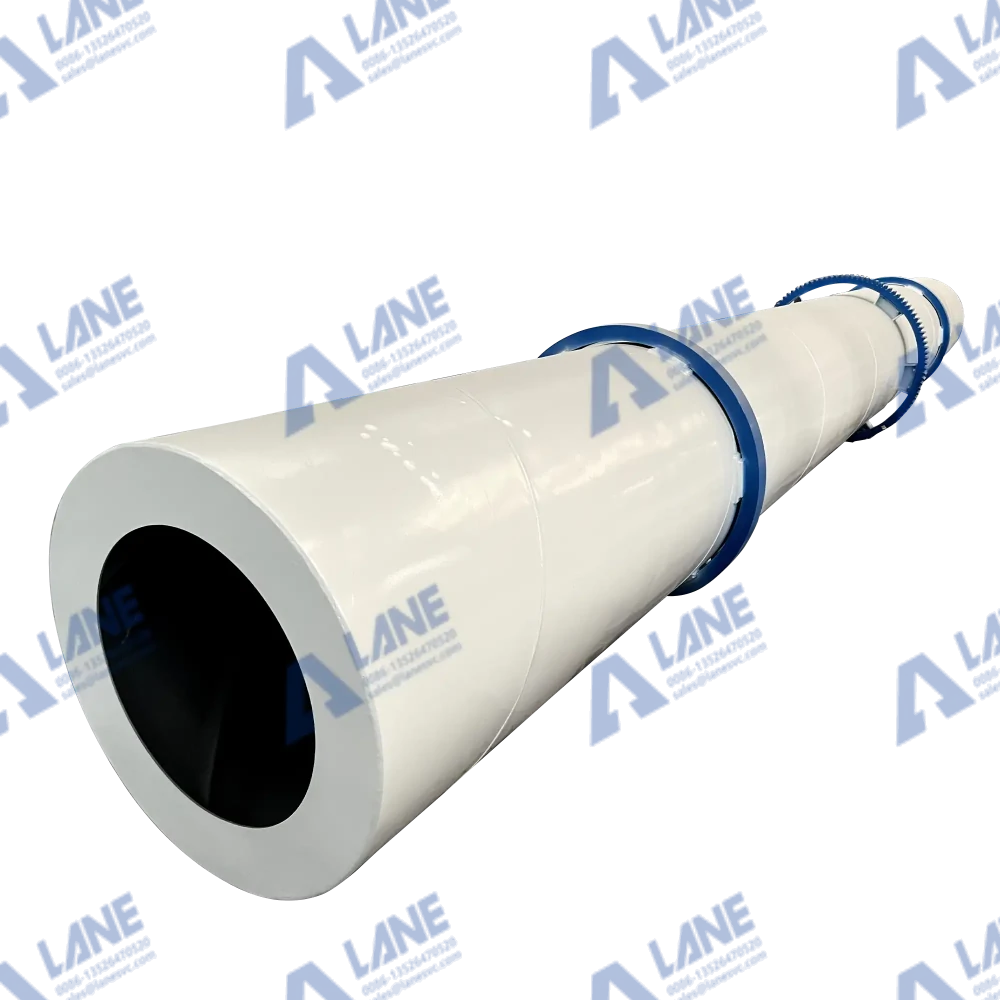

Inside the rotary dryer, fertilizer slowly moves forward while warm air passes around it. The heat is not too strong, but steady. This allows water to escape little by little without damaging the fertilizer. A well-designed phosphate fertilizer dryer and cooler system makes sure that every particle is treated evenly, so the quality stays the same from start to finish.

Drying also helps improve strength. Once water is removed, fertilizer particles become harder and less likely to break during transport. This makes packaging easier and reduces waste.

After drying, fertilizer is still very hot. Hot fertilizer cannot be packed right away because heat can bring moisture back from the air. This may cause the fertilizer to stick together or lose its shape.

The rotary cooler gently lowers the temperature. Cool air flows through the fertilizer until it reaches a safe level. Only then is it ready for storage or packaging. This step protects all the work done during drying. Without cooling, drying alone would not be enough. That is why the phosphate fertilizer dryer and cooler system always works as one complete unit.

The working process of this system is simple but effective. Wet phosphate fertilizer enters the dryer through a feeding mechanism. Inside, it moves on a rotating drum or a fluidized bed, depending on the design. Hot air passes through the material, removing moisture evenly. Temperature sensors help control the heat, so the fertilizer never gets too hot.

After drying, the fertilizer moves directly into the cooler. Here, fans blow ambient air through the material, lowering its temperature. The cooler usually has a design similar to the dryer, so particles continue moving smoothly. Once cooled, the fertilizer flows out to storage or packaging areas. The whole process is continuous and automated, which makes factory operation easier.

In a real factory, speed and stability matter a lot. Machines must work smoothly, and workers need clear steps to follow. Without proper drying and cooling, production may stop often, and workers may need to fix problems again and again.

With a phosphate fertilizer dryer and cooler system, the production line becomes more organized. Fertilizer moves from one stage to the next without long waiting times. The working area stays cleaner, and product quality becomes more stable. This helps factories meet delivery schedules and customer needs.

Even though this equipment does an important job, its working idea is easy to understand. Materials go in wet and hot, then come out dry and cool. The process is smooth and continuous.

A good phosphate fertilizer dryer and cooler system is also designed to handle different production sizes. Whether the factory is small or large, the system can be adjusted to match real needs. This flexibility makes it useful for many types of fertilizer plants.

Energy use is a big concern in factories. Poor equipment can waste heat and electricity. A well-made system uses heat wisely and controls airflow carefully.

The phosphate fertilizer dryer and cooler system helps reduce energy waste by keeping temperatures stable and avoiding repeated heating. At the same time, it shortens production time. Faster production with stable quality means better profits in the long run.

Farmers may not see the machines, but they feel the results. Dry and cool fertilizer flows easily and spreads evenly in the field. It does not block spreading machines and does not form hard lumps.

Because of the phosphate fertilizer dryer and cooler system, fertilizer products look cleaner, feel stronger, and perform better. This builds trust between fertilizer producers and users.

Even simple systems need some care. Operators should check airflow, temperature, and particle movement every day. Cleaning dust or leftover material helps keep the system working smoothly. Small inspections prevent big problems later.

The phosphate fertilizer dryer and cooler system is designed for easy maintenance. Bearings, fans, and heating pipes are accessible. With basic daily checks, the system can run for many years without major issues. This reduces downtime and ensures steady production.

At LANE, we have spent more than 20 years working with fertilizer machinery in China. Our company understands real factory challenges. When we build a phosphate fertilizer dryer and cooler system, we think about safety, stability, and easy use.

We have our own engineering team and handle design, manufacturing, and installation ourselves. This allows us to provide complete fertilizer production lines based on customer needs. LANE is proud to support our clients not only with equipment, but also with installation help and after-sales service. Our machines meet ISO 9001 and CE standards, which shows our focus on quality.

Looking Ahead

As agriculture continues to grow, fertilizer demand will remain strong. Production lines must be efficient and reliable. The phosphate fertilizer dryer and cooler system will continue to be an important part of fertilizer manufacturing.

Simple design, steady performance, and real results make this equipment valuable today and in the future. By understanding how drying and cooling work, factories can improve quality, save energy, and provide farmers with fertilizer that is ready to use.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.