Why Phosphate Fertilizer Is Important

Phosphate fertilizer helps plants grow strong and healthy. If you want to make fertilizer yourself, choosing the right phosphate fertilizer plant manufacturer is very important. A good phosphate fertilizer plant manufacturer can guide you through setting up your line so every batch is consistent. A production line has different machines that work together to turn raw materials into fertilizer that’s easy to handle, store, and use. A well-designed line saves time, reduces waste, and makes sure every batch is the same. Working with a reliable phosphate fertilizer plant manufacturer also helps you avoid mistakes and ensures you get the best results.

Measuring Materials with Dynamic Scales

The first step is measuring how much of each ingredient you need. A dynamic batching scale does this automatically. It weighs phosphate, nitrogen, and other materials for each batch. Measuring correctly is very important—if the amounts are wrong, the fertilizer won’t work well. Using a good phosphate fertilizer plant manufacturer ensures the scale is accurate and suitable for your production needs. A dynamic scale is fast and reliable, which saves time and makes sure every batch is consistent.

Crushing Materials with Vertical Crushers

Many raw materials come in big lumps. A vertical crusher breaks them into smaller pieces. Smaller pieces mix better and are easier to turn into granules later. Crushing also helps the fertilizer spread evenly when used on crops. Vertical crushers are strong, easy to use, and handle hard materials without trouble. A professional phosphate fertilizer plant manufacturer will choose the right crusher to match your raw materials and production line.

Mixing Ingredients with Double-Shaft Mixers

After crushing, the materials need to be blended. A double-shaft mixer mixes everything evenly so that every granule has the same nutrients. Even mixing is important—if the mixture is uneven, some parts of the fertilizer won’t work well. This machine can handle a lot of material at once and works quickly, making the whole process more efficient. A reliable phosphate fertilizer plant manufacturer will ensure your mixer is the right size and performs well for your production volume.

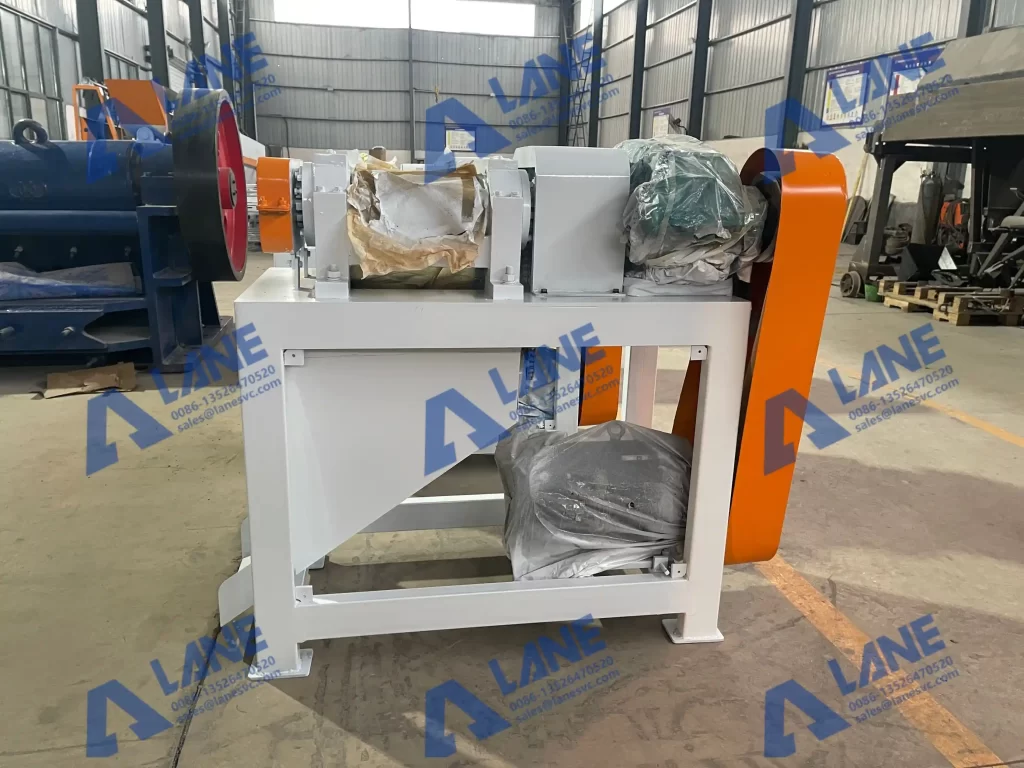

Making Granules with Double Roller Granulators

The mixed powder is then shaped into granules with a double roller granulator . This machine presses the powder into small, solid granules that are easy to handle, store, and use. The granules are strong and uniform, so they don’t break during transport. You can also adjust the granule size depending on your needs. A skilled phosphate fertilizer plant manufacturer will help you select the right granulator to produce high-quality granules efficiently.

Drying Granules with Rotary Drum Dryers

The granules still have moisture after forming. A rotary drum dryer removes water from the granules. Dry granules are less likely to stick together, last longer, and are easier to store. This machine uses hot air to dry granules evenly and keeps production running continuously. Choosing a trusted phosphate fertilizer plant manufacturer helps ensure your dryer is suitable for your production scale and material type.

Cooling Granules with Rotary Drum Coolers

After drying, the granules are hot. A rotary drum cooler lowers their temperature and makes them firm. Cooling prevents clumping and makes granules easy to handle and pack. It also improves the look and feel of the fertilizer. A professional phosphate fertilizer plant manufacturer can match the cooler to your dryer and production line for best results.

Sorting Granules with Rotary Drum Screening Machines

A rotary drum screening machine sorts the granules by size. Large or small pieces are removed and sent back for reprocessing. Screening makes sure that only uniform granules move forward. Uniform size helps the fertilizer spread evenly when applied to crops and improves quality. A skilled phosphate fertilizer plant manufacturer will ensure the screening system fits your granule size requirements.

Coating Granules with Coating Machines

Some production lines use apolishing-machine. Coating protects granules from moisture, reduces dust, and keeps nutrients from being lost. This is helpful for phosphate fertilizers, which can clump if the air is humid. Coated granules are easier to store, transport, and use. A knowledgeable phosphate fertilizer plant manufacturer can set up the coating system for optimal results.

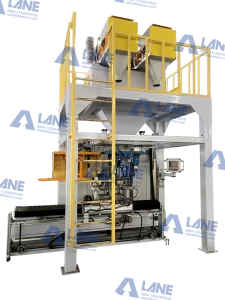

Packing the Fertilizer

The final step is packing. A packaging machine fills bags with the right amount of fertilizer and seals them. Automatic packing is faster, saves labor, and keeps the fertilizer clean. Good packaging protects the fertilizer during storage and shipping and makes it ready for sale. Choosing the right phosphate fertilizer plant manufacturer ensures the packing system matches your production speed and bag size needs.

LANE Advantages

LANE has over 20 years of experience as a phosphate fertilizer plant manufacturer in China. We provide complete production lines that are easy to use and meet ISO 9001 and CE standards. We help with installation and basic support so your line runs smoothly. Our focus is on practical machines that make production simple and reliable.

Choosing the Right Manufacturer

Working with a reliable phosphate fertilizer plant manufacturer saves time, reduces mistakes, and helps produce fertilizer that works well for farmers. Every machine, from measuring scales to packaging, is important for making high-quality fertilizer.

Conclusion

A phosphate fertilizer production line has many steps: crushing, mixing, granulating, drying, cooling, screening, coating, and packing. Each step matters to make good fertilizer that’s easy to use and store. Choosing LANE as your phosphate fertilizer plant manufacturer gives you reliable machines, guidance, and support. With the right machines and a trusted manufacturer, you can produce fertilizer that works well, lasts long, and helps crops grow strong.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.