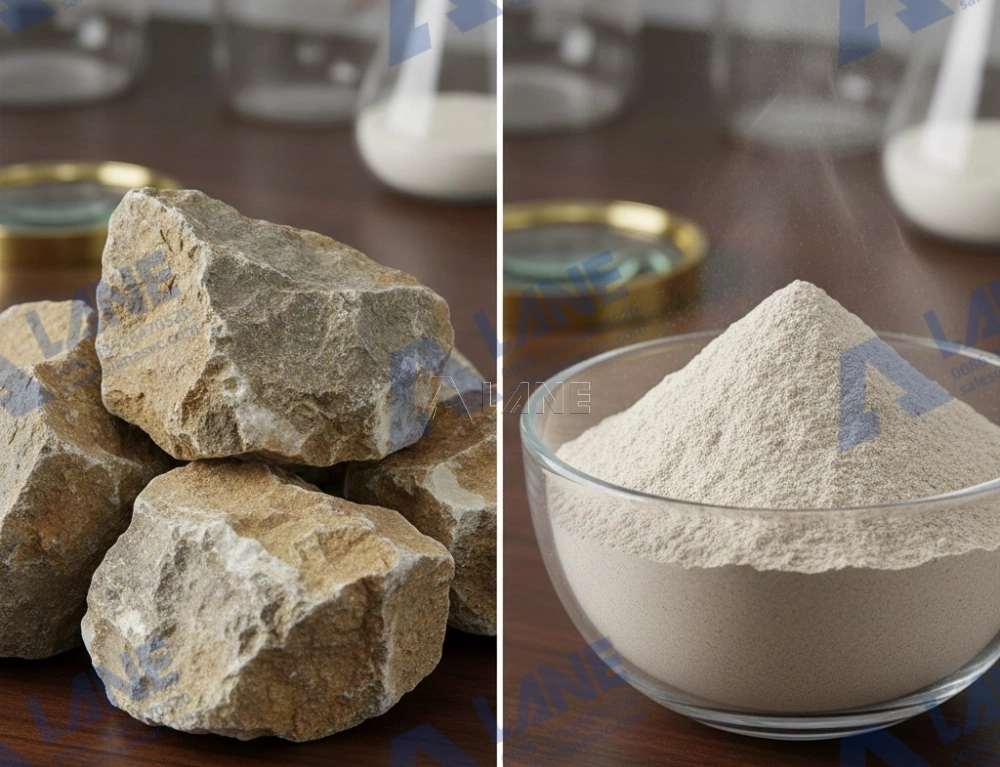

Making MAP (Monoammonium Phosphate) fertilizer needs good raw materials and the right machines. At our company, we use phosphate rock powder as raw material. We turn it into granules that farmers can use easily. In this article, I will explain how we do it and what machines we use. We want to show how simple and reliable our production process is. This process helps farmers get fertilizer that works well and is safe to use.

We start with phosphate rock powder as raw material. First, the rocks are crushed and ground into fine powder. This makes it easier to mix with ammonia later. Crushing and grinding also help remove big pieces that could make the granules uneven.

Equipment used:

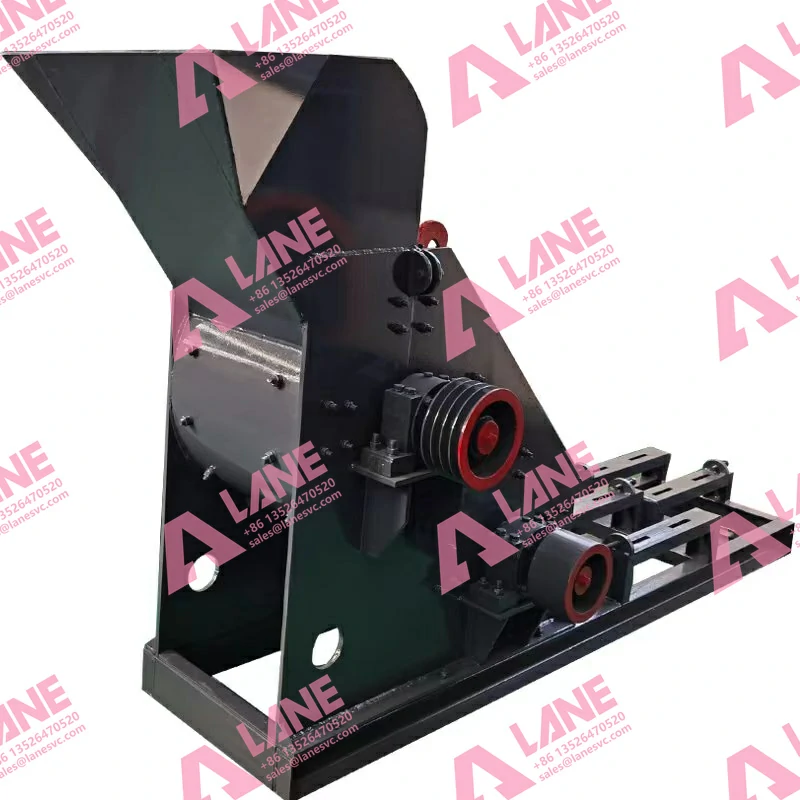

Jaw crusher or hammer crusher for breaking rocks into smaller pieces

Ball mill or Raymond mill for grinding powder fine enough for fertilizer

Vibrating screen to separate different sizes of powder and remove large chunks

These machines make the powder uniform and clean. Using phosphate rock powder as raw material helps us make fertilizer with the right quality. We also check the powder to make sure it has the right amount of phosphorus. This step is very important because it affects the fertilizer’s strength and quality. Using good phosphate rock powder as raw material helps make sure the final product is strong and works well in the fields.

Next, we mix the phosphate rock powder with additives and sometimes a little water. This step helps the powder stick together better in the next step.

Equipment used:

Ribbon blender or paddle mixer for even mixing

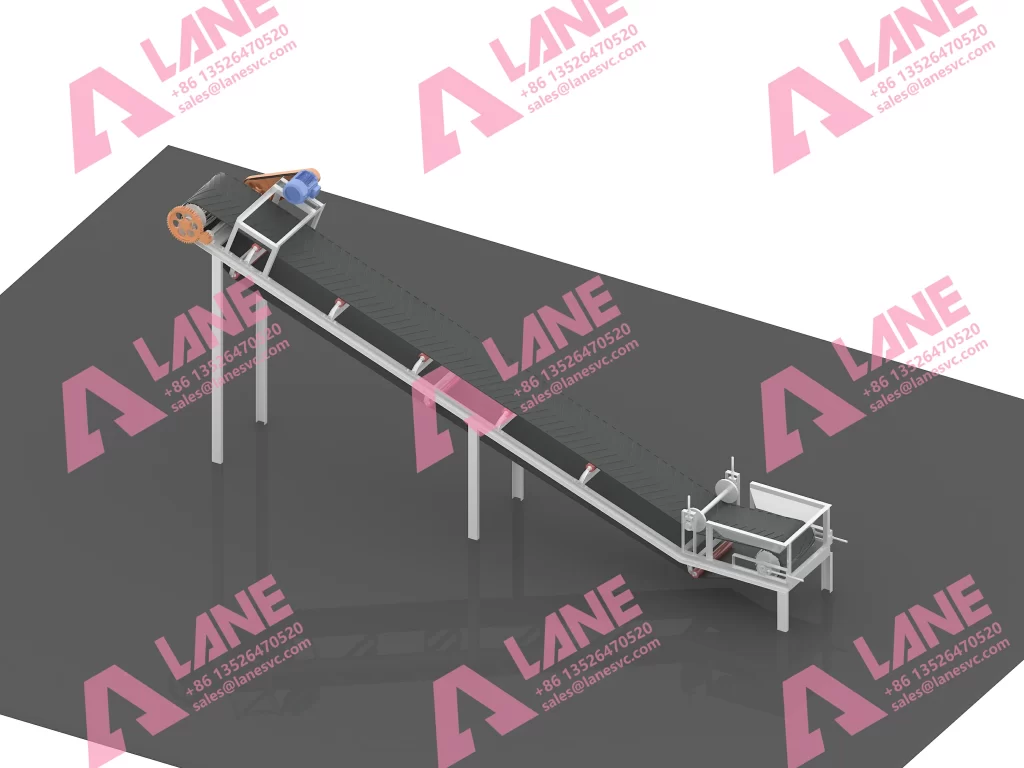

Belt conveyor or screw conveyor to move the mix to the granulator

The mixture is then ready for granulation. Using phosphate rock powder as raw material helps the granules form well and keeps the nutrients consistent. At this stage, we also make sure the moisture is correct. Too much or too little water can make the granules weak or sticky. We watch this carefully to get the best results.

In the granulator, phosphate rock powder as raw material reacts with ammonia to form MAP granules. This is the most important step in making fertilizer.

Equipment used:

Double roller (twin-roll) granulator for making strong, round granules

Ammonia injection system for adding ammonia safely and evenly

We control the size and hardness of the granules. This is important because farmers need fertilizer that is easy to spread and does not break easily. Using phosphate rock powder as raw material ensures the chemical reaction works well and the granules are strong. We also check that the granules are round and smooth. This makes them easier to handle and store.

After granulation, the wet granules need to dry before they can be used or stored. Drying removes extra moisture and makes the granules hard.

Equipment used:

Rotary dryer to remove moisture evenly

Rotary cooler or fluidized bed cooler to cool the granules down

Drying and cooling help keep the granules strong and stable. Using phosphate rock powder as raw material helps keep the nutrients consistent. We also make sure the granules do not crack during drying. The drying and cooling step makes the fertilizer ready for screening and coating.

After cooling, we separate granules by size. We also add a coating to reduce dust and prevent clumping.

Equipment used:

Vibrating or rotary screen to sort granules by size

Crusher to recycle small pieces back to the granulator

Drum coater to cover the granules with a thin layer for protection

Screening and coating make the granules look good and last longer. Using phosphate rock powder as raw material helps make sure all granules are the same size and strong. The coating also makes it easier for farmers to store and spread the fertilizer. This step is simple but very important for quality.

Finally, the MAP granules are ready for packaging.

Equipment used:

Automatic packing machine for accurate weight

Conveyor to move bags to storage or shipping areas

Bag sealing machine to close bags securely

Using phosphate rock powder as raw material keeps the product consistent. We can also pack in bulk or small bags depending on customer needs. Packaging protects the fertilizer and makes it easy to transport. We check every bag to make sure it has the right weight and that the granules are not broken.

We have over 20 years of experience in making fertilizer machines. Our engineers can design, make, and install machines for any production line. We offer full service including installation, maintenance, troubleshooting, and upgrades. Our goal is to make the production line simple to run and easy to maintain.

All our machines meet ISO9001 and CE standards. Our main products are MAP production lines, NPK fertilizer lines, organic fertilizer machines, and compound fertilizer machines. Using phosphate rock powder as raw material, our machines help produce high-quality fertilizer efficiently. We also help our clients solve problems and keep the machines running smoothly. Our team is ready to support customers at any time.

From phosphate rock powder as raw material to finished MAP granules, every step needs the right machines and careful handling. With our experience and advanced equipment, we make reliable fertilizer for farmers. Using phosphate rock powder as raw material ensures the granules are consistent, strong, and nutrient-rich. Our company provides guidance, quality machines, and support at every step. We want every farmer to get fertilizer that works well and helps crops grow better. Using simple and clear steps, we make the whole process easy to understand and efficient.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.