In today’s agriculture news, efficiency and soil health are hot topics. Many producers choose to produce granular phosphate fertilizer to improve handling and crop nutrition. Farmers want fertilizers that are easy to use, store, and transport, while still giving crops steady nutrition. That’s why many producers choose to produce granular phosphate fertilizer instead of powders or irregular materials. Granules flow well, spread evenly, and dissolve at a controlled rate in the soil.

In this article, we’ll take you inside a real production line. We’ll show how phosphate fertilizer is made step by step, what equipment is used, and how a smart production setup can make daily work smoother and more reliable. No heavy jargon here—just a practical look at how things really run in a modern fertilizer plant.

Phosphate fertilizer mainly supplies phosphorus, one of the three core nutrients plants need. It helps roots grow strong and supports flowering and fruit development. Granular forms are especially popular because they are less dusty and easier to handle.

When companies plan to produce granular phosphate fertilizer, the goal is simple: turn raw phosphate materials into uniform, strong granules that keep their shape during transport and storage. To do this well, the right process and machines matter just as much as the formula itself.

Every good product starts with good ingredients. Common raw materials include phosphate rock powder, monoammonium phosphate (MAP), diammonium phosphate (DAP), or other phosphorus-rich sources. Depending on the formula, small amounts of fillers or binders may also be added.

Before mixing, materials are checked for moisture and particle size. Clean, well-prepared raw materials make the next steps much easier and help ensure stable granulation later on. This is the foundation for anyone looking to produce granular phosphate fertilizer at a consistent quality level.

Once raw materials are ready, they move to the batching system. Here, ingredients are weighed according to the formula. Accuracy is key, but the process itself doesn’t need to be complicated.

A double screw cone mixer is often used at this stage. This machine blends materials gently and evenly, thanks to its dual screw design and conical structure. It ensures that each granule will have a consistent nutrient content, which farmers really appreciate in the field. At this point, the material still looks like powder, but it’s now ready for shaping.

To meet market demand and ensure quality, factories aim to produce granular phosphate fertilizer that is uniform, strong, and easy to handle.

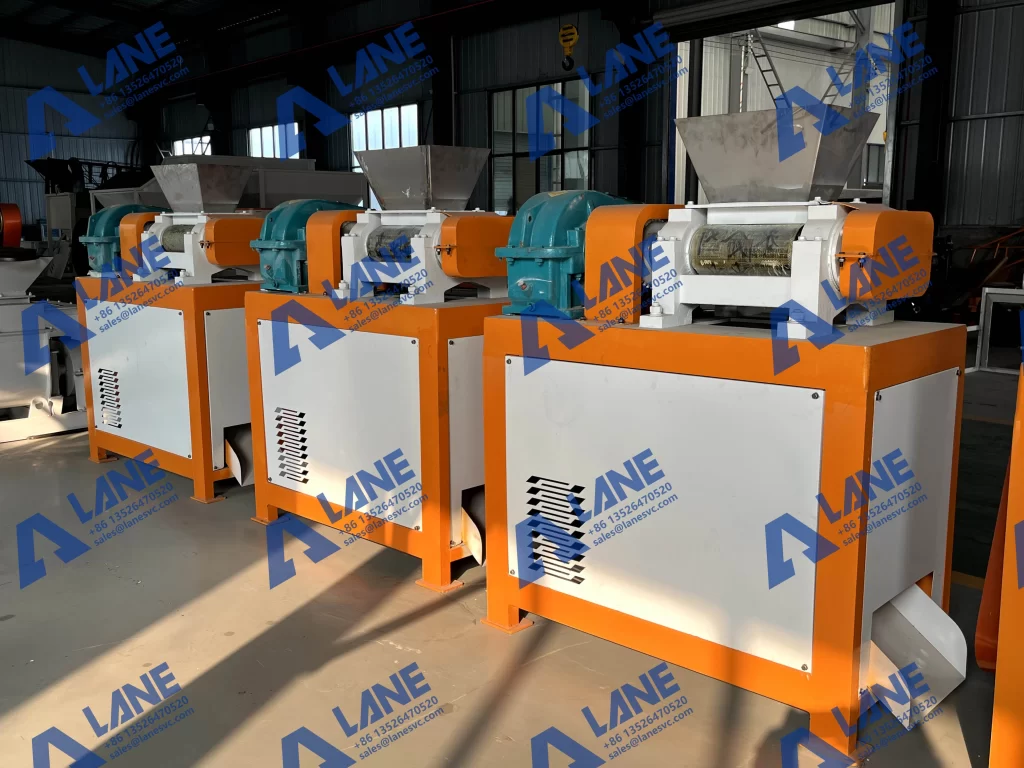

Granulation is the heart of the process. To produce granular phosphate fertilizer efficiently and with low energy use, many factories choose a double roller extrusion granulator.

This machine works by pressing the mixed powder between two counter-rotating rollers. The pressure forms compact sheets or strips, which then break into granules. The process is dry, meaning no need for large amounts of water or steam. This keeps costs down and makes the line easier to control.

The double roller extrusion granulator is valued for its simple structure, steady output, and strong granules. It’s a practical choice for both small and large production lines.

After granulation, not all particles are the same size. Some may be too large, others too small. To solve this, the material passes through a crusher and then a screening machine.

Oversized granules are crushed and sent back for reprocessing. Fine powder is also returned to the granulator. Only qualified granules move forward. This closed-loop system helps reduce waste and keeps production efficient when you produce granular phosphate fertilizer on a daily basis.

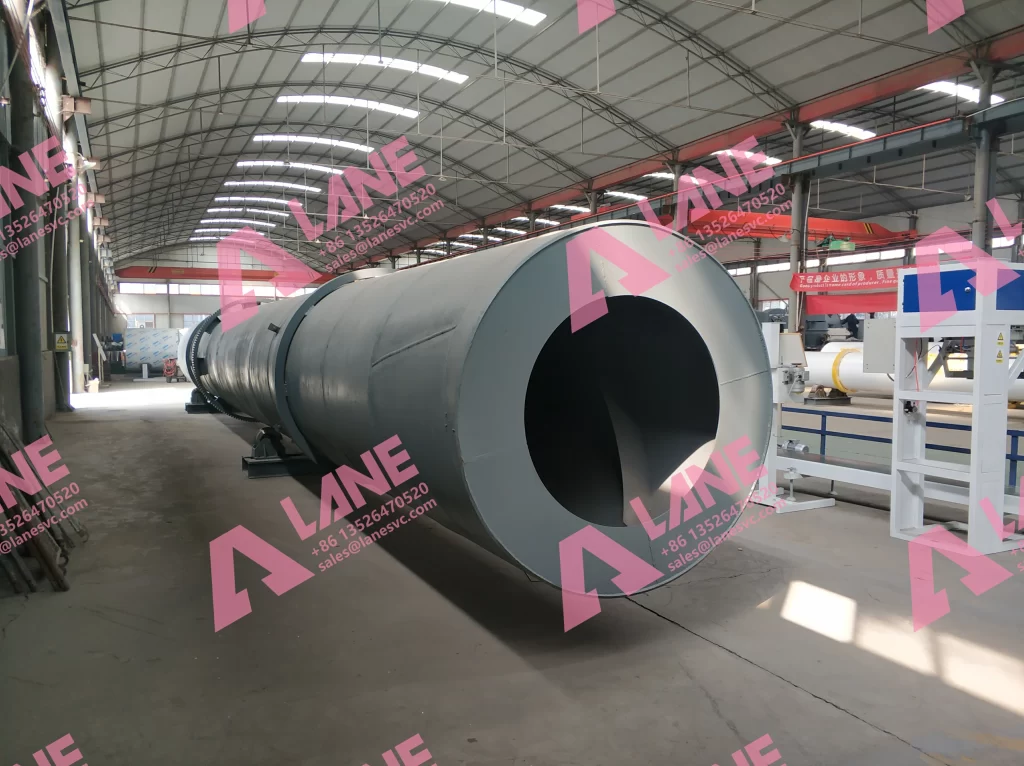

Fresh granules often contain a bit of surface moisture and heat from processing. A rotary dryer is used to remove excess moisture, followed by a rotary cooler to bring the temperature down.

Dry, cool granules are stronger and less likely to break during storage or transport. This step may look simple, but it plays a big role in final product quality and customer satisfaction.

Some producers add a coating step. A polishinging machine sprays a thin layer of oil or anti-caking agent onto the granules. This helps prevent clumping and improves flow.

While optional, Polishing is popular in many markets. It gives the product a cleaner look and makes spreading easier for end users. It’s another detail that can add value when you produce granular phosphate fertilizer for competitive markets.

The final step is packing. Automatic packing machines weigh and fill bags or bottles, then seal them for shipment. Common package sizes range from small retail bags to large bulk sacks.

Clear labeling and neat packaging turn a technical product into something market-ready. At this point, the fertilizer is no longer just material—it’s a finished product ready for farms and distributors.

At LANE, we’ve been working in the fertilizer machinery field for over 20 years. During that time, we’ve helped customers around the world produce granular phosphate fertilizer with stable output and reliable quality.

We don’t just sell single machines. We design complete production lines based on your capacity, raw materials, and site conditions. Our professional engineering team handles equipment design, manufacturing, on-site installation, and commissioning. If something needs adjusting, we customize it—no copy-paste solutions.

Our core products cover organic fertilizer, compound fertilizer, and liquid fertilizer equipment. All machines are built under ISO9001 quality management standards and meet CE certification requirements. After installation, we stay involved with full after-sales support, including maintenance guidance, troubleshooting, and future upgrades. For us, long-term performance matters more than quick delivery.

Around the world, demand for phosphate fertilizer remains steady. Farmers want products that are easy to apply and deliver clear results. Granular forms fit perfectly into modern farming practices.

As more producers look to upgrade old lines or start new projects, the focus is on efficiency, low energy use, and stable quality. That’s why well-designed systems to produce granular phosphate fertilizer are gaining attention across different regions and scales.

Making fertilizer doesn’t have to be complicated. With the right raw materials, clear process steps, and dependable equipment, the whole line can run smoothly day after day. From mixing to granulation, drying, and packing, each step plays its part.

If you’re planning a new project or improving an existing one, understanding the full process is the first step toward success. And with the right partner by your side, producing high-quality granular phosphate fertilizer can be a steady and rewarding business.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.