If you are interested, please feel free to contact us at any time.

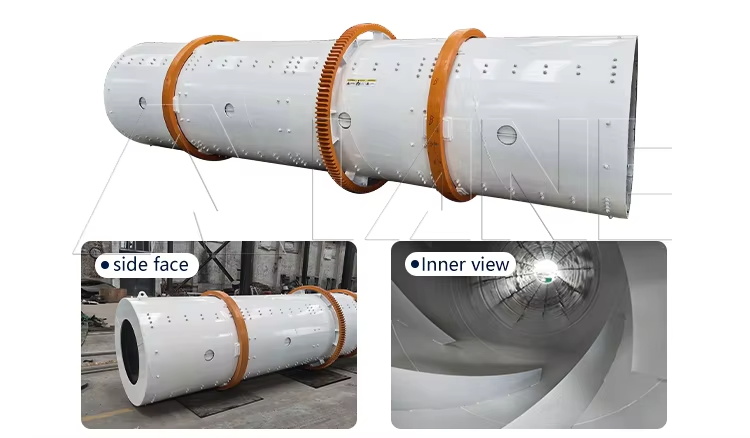

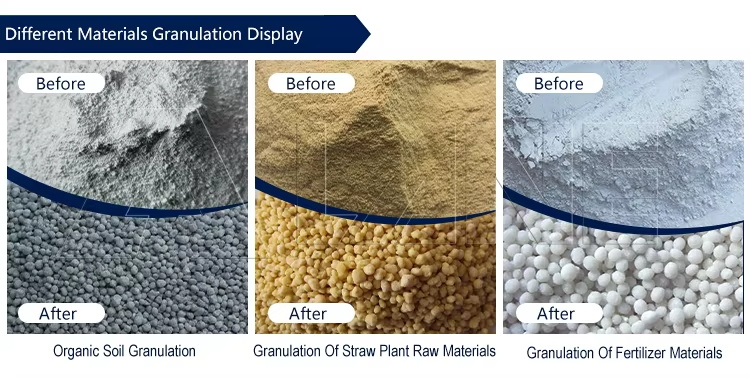

The Rotary Drum Granulator is a machine that granulates materials into a specific shape. It is suitable for large-scale production of cold and hot granulation and high and low concentration compound fertilizers. More importantly, it is one of the key equipment for manufacturing compound fertilizers. You can also equip it with other machines to form a complete compound fertilizer production line. LANE can provide you with complete supporting facilities, including batching machines, screening machines, mixers, etc.

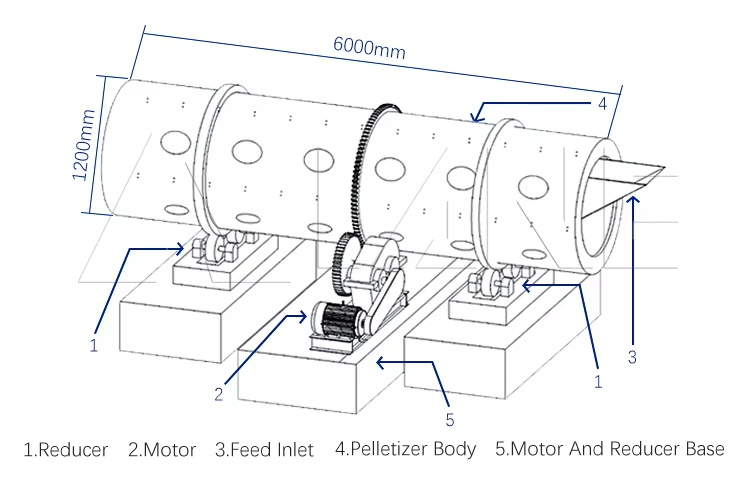

Composition Structure

Machine body: The rotating part of the whole machine body is supported by the bracket, which is subject to greater force. Therefore, the support wheel frame of the machine is welded with medium carbon steel plate and channel steel, and has passed strict quality control and special process requirements.

Transmission part: The transmission part of the whole Rotary Drum Granulator is particularly important. The whole machine body works on this. The transmission frame is welded with high-quality channel steel and has passed strict quality requirements. The main motor and reducer installed on the transmission frame are all ISO national inspection-free products with reliable quality.

Big gear: Fixed on the machine body, meshing with the transmission pinion, driving the machine body to work in opposite directions. It uses high-tech wear-resistant materials to make the machine have a longer service life.

Working Principle

Basic process: The main motor drives the belt and pulley, which is transmitted to the driving shaft through the reducer, and the split gear installed on the driving shaft meshes with the big gear ring fixed on the machine body, and works in opposite directions. The material is added from the feed end, and is made into particles through the special structure inside the cylinder, and finally flows out through the discharge port.

Detailed steps: Steam heating is introduced to increase the material temperature, so that the material has low moisture content after being balled, and the drying efficiency is improved; rubber engineering plastics are used as linings, so that the raw materials are not easy to stick to the barrel, and they play an anti-corrosion and heat preservation role.

Advantages

High balling rate: The balling rate reaches 70%, with a small amount of return material, and the return material has a small particle size and can be re-granulated.

Energy saving and environmental protection: Steam heating is introduced to increase the material temperature, so that the material has low moisture content after being balled, and the drying efficiency is improved; rubber engineering plastics are used as linings, so that the raw materials are not easy to stick to the barrel, and they play an anti-corrosion and heat preservation role.

Large output: large output, low power consumption, and low maintenance costs.

Wide range of applications: Suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers.

In general, the Rotary Drum Granulator has become an indispensable equipment in fertilizer production due to its unique design, efficient production capacity and wide range of applications.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.