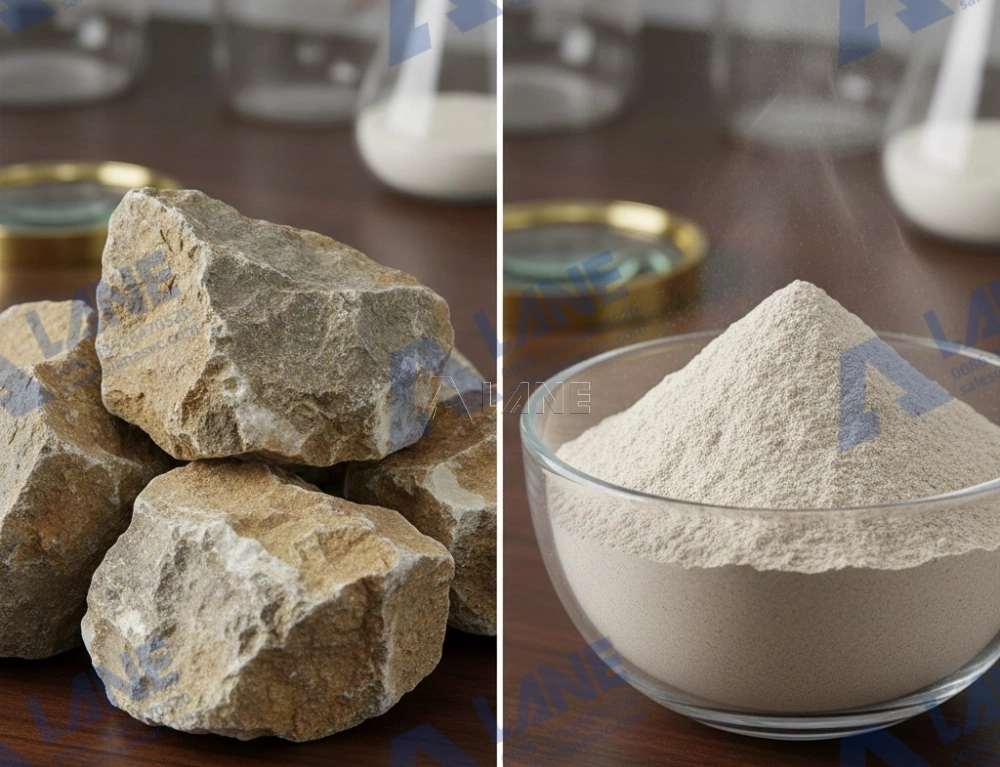

If you have ever visited a fertilizer plant or a mining facility, you know that the “grinding” stage is where the magic happens. It is the process of taking large, raw materials and turning them into fine, usable particles. However, not all machines do this the same way.

At our company, we often get asked which machine is better for a specific project. While both machines aim to reduce particle size, their internal “personalities” are quite different. By understanding the six major differences between ball mills and pulverizers, you can save your business time, energy, and money.

The first and most obvious of the six major differences between ball mills and pulverizers is how they actually break down the material.

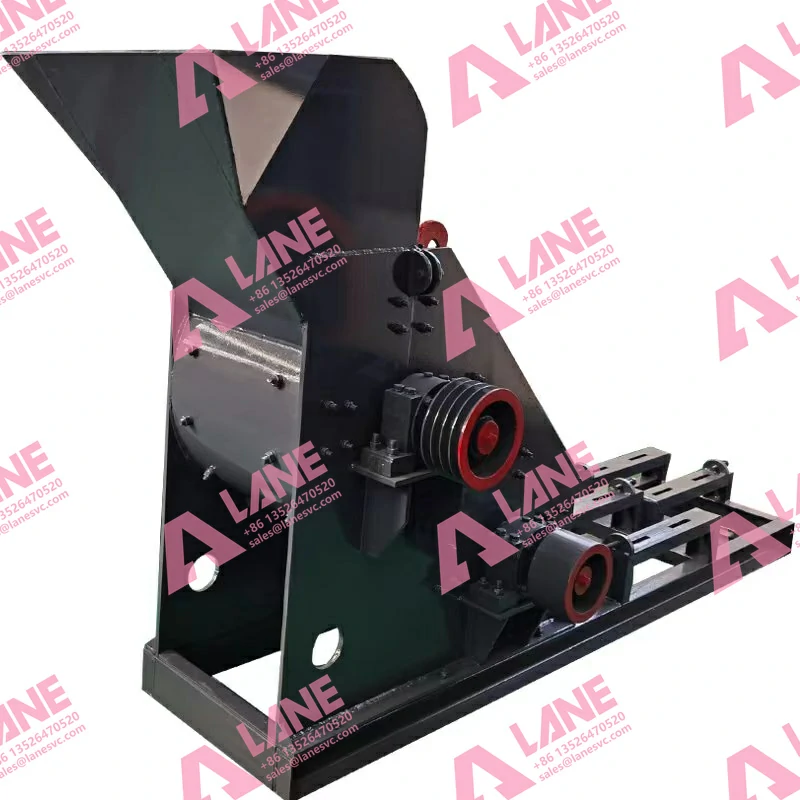

Ball Mills: Imagine a large horizontal drum filled with steel balls. As the drum rotates, the balls are lifted and then fall back down, crushing the material through impact and attrition. It is a heavy-duty, “tumbling” process.

Pulverizers: These machines usually rely on high-speed impact or shearing. Instead of tumbling balls, they often use hammers, blades, or plates to “shatter” the material into pieces.

If your material is very hard or abrasive, the ball mill’s heavy impact is often the winner. If you need a quick, shattering action for softer materials, a pulverizer is your friend.

When we look at the six major differences between ball mills and pulverizers, we have to talk about the “fineness” of the result.

Ball mills are the champions of extreme fineness. If you need a product that feels like flour or even finer, a ball mill is the go-to equipment. Pulverizers, on the other hand, are excellent for creating small granules or medium-fine powders. While some high-end pulverizers can get very fine, they generally don’t reach the consistent “ultra-fine” levels that a ball mill can achieve over a long cycle.

Efficiency is a huge factor for any factory owner. This is one of the most debated points among the six major differences between ball mills and pulverizers.

Generally, pulverizers are seen as more energy-efficient for materials that don’t require extreme grinding. They work fast and use high speed to get the job done. However, ball mills—while they may use more energy per hour—are more efficient when dealing with incredibly hard materials that a pulverizer simply couldn’t handle without breaking.

Not all raw materials are created equal. Some are rocks, some are crystals, and some are slightly damp.

Ball Mills: These are the “beasts” of the industry. They can handle very hard, abrasive materials (like gold ore or hard phosphate rock) without much wear and tear on the machine shell.

Pulverizers: These are better suited for materials with low to medium hardness. They are also often better at handling materials with a bit more moisture, as some pulverizer designs include airflow that helps dry the material as it grinds.

Understanding this specific point among the six major differences between ball mills and pulverizers will prevent you from damaging your equipment.

Maintenance is where the long-term costs hide. In our 20 years of experience at LANE, we’ve seen how maintenance schedules can make or break a production budget.

In a ball mill, the primary “wear parts” are the steel balls and the internal liners. These are easy to monitor and replace. In a pulverizer, you are often dealing with high-speed hammers or blades. Because they spin at such high velocities, they can wear down faster if you are processing tough materials. This constant replacement of small, high-speed parts is a key highlight when comparing the six major differences between ball mills and pulverizers.

Finally, let’s look at the “footprint.” Ball mills are typically large, heavy, and require a very solid foundation. They are slow-moving but massive. Pulverizers are generally more compact. If your factory floor has limited space, a pulverizer might fit more easily into your layout.

However, size isn’t everything. A larger ball mill might replace the need for several smaller machines, so it’s always a balance of space versus total output.

Common Industry Questions

Many clients ask us why we emphasize the six major differences between ball mills and pulverizers so early in the planning stage. The answer is simple: choosing the wrong machine can double your operational costs over time.

After reviewing the six major differences between ball mills and pulverizers, you might still be wondering: “Which one is right for my specific fertilizer line?”

This is where we come in. At LANE, we don’t just sell machines; we provide solutions. With over 20 years of professional experience in the Chinese fertilizer machinery sector, we have seen every challenge imaginable. We focus on making your production as smooth as possible.

Our Professional Edge

We are proud to have a professional engineering team that specializes in customized services. We don’t believe in “one size fits all.” Whether you are building a new NPK production line or upgrading an organic fertilizer plant, we design, manufacture, and install the entire line tailored to your specific goals.

One-Stop Service

When you work with us, you get a one-stop service experience. This means we are with you from the moment the equipment is installed to the years of operation that follow. Our team provides:

We specialize in fertilizer production lines, NPK lines, and both organic and compound fertilizer equipment. Our goal is to ensure your production line runs stably and efficiently, year after year.

Identifying the six major differences between ball mills and pulverizers is the first step toward a successful facility. One is a slow, steady, and powerful crusher of hard materials, while the other is a fast, efficient, and compact precision tool.

In many cases, the choice depends on your specific “recipe” and the hardness of your raw materials. If you choose a ball mill for soft material, you might be wasting energy. If you choose a pulverizer for granite-hard rock, you might face constant repairs.

Knowing the six major differences between ball mills and pulverizers allows you to talk to equipment providers with confidence. At our company, we take that knowledge and turn it into a high-performing reality for your business.

We know that every project is unique. If you are still unsure about the six major differences between ball mills and pulverizers and how they apply to your specific material, let us help you. We can look at your requirements and suggest the perfect fit for your production line.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.