If you are interested, please feel free to contact us at any time.

Stainless steel horizontal screw belt mixer is a kind of high-efficiency mixing equipment widely used in many industries. It mixes materials evenly through a specific mechanical structure.Stainless steel horizontal screw belt mixer is mainly composed of U-shaped cylinder, ribbon stirring blades and transmission parts. The ribbon blades are generally made of double or triple layers. The outer spiral gathers the materials from both sides to the center, and the inner spiral transports the materials from the center to both sides to form convection mixing. This model is suitable for mixing viscous or cohesive powders and particles and adding liquids and paste materials to powders and particles. It is particularly suitable for mixing viscous materials.

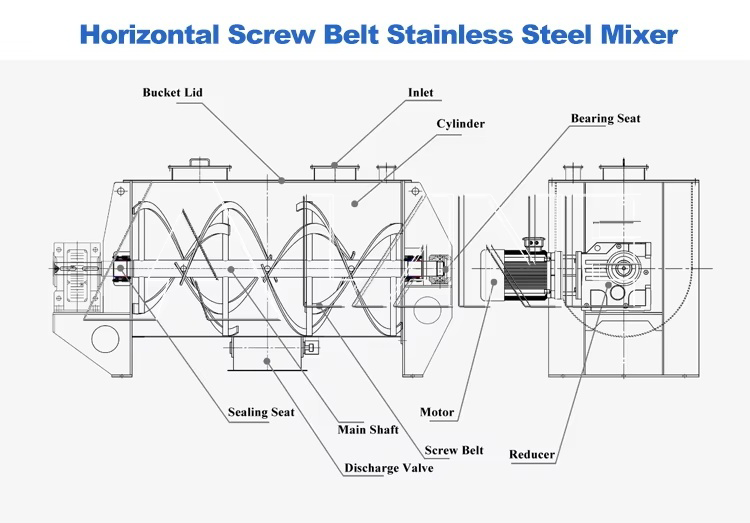

Composition Structure

U-shaped container: The U-shaped long cylinder structure ensures the small resistance movement of the mixed materials (powders, semi-fluids) in the cylinder.

Ribbon stirring blades: The ribbon blades are generally made of double or triple layers. The outer spiral gathers the materials from both sides to the center, and the inner spiral transports the materials from the center to both sides, which can form more vortices in the flow of materials, speed up the mixing speed, and improve the mixing uniformity.

Transmission parts: The motor and the mixing main shaft are directly connected through a cycloidal pinwheel reducer, which has a simple structure, high operating reliability and easy maintenance.

Working Principle

Basic process: When the motor drives the mixing shaft of the agitator to rotate, the agitator shears, squeezes and flips the material to make the material evenly mixed in the tank.

Detailed steps: First, add the material to the tank; then, start the motor and agitator to make the material rotate and shear at high speed in the tank; finally, adjust the heating or cooling device as needed to achieve the required process conditions.

Advantages

High mixing uniformity: It can make materials with a ratio of 1:10000 evenly mixed, especially for materials with larger specific gravity characteristics.

Fast mixing speed and high efficiency: Usually each batch of materials is fully mixed and stirred in 1-10 minutes, which is 6-10 times or more efficient than other mixers.

Fast and convenient discharging: Usually a batch of materials is discharged in 1 to 2 minutes.

Large loading capacity: The stainless steel horizontal screw belt mixer usually has a loading capacity (loading factor) of more than 70%.

Small amount of residue: Since the gap between the outer spiral ribbon and the U-shaped barrel wall is very small during the processing, and the spiral ribbon is always running during the discharge, the material moves toward the discharge valve, and almost all of it is discharged.

Gentle mixing process: The original state of the material is basically not destroyed.

No pollution to the material: The mixing mechanism of the stainless steel horizontal screw belt mixer is an integral type, safe and reliable, all the corner welds are smoothly transitioned and easy to clean; the lubrication parts are all outside the barrel, no oil dripping and grinding debris penetrate into the material, and can be sealed to isolate dust in the air from entering the material.

Low requirements for the plant: The stainless steel horizontal screw belt mixer is horizontal, and various forms of drive devices and discharge positions can be selected at will, not restricted by the height of the plant and the floor area.

The equipment runs smoothly and reliably: there are few wearing parts, long service life, convenient maintenance and simple operation.

In general, the Stainless steel horizontal screw belt mixer has been widely used and recognized in many industries for its efficient production capacity, high-quality product output, energy-saving and environmental protection characteristics, and flexible production adaptability.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.