Sugarcane is a “hungry” crop. To grow tall, juicy stalks with high sugar content, it requires a steady supply of nutrients, specifically phosphorus and nitrogen. This is where Diammonium Phosphate (DAP) comes in. For many producers, the secret to success is the ability to boost sugarcane yield with high-efficiency DAP fertilizer production line setups that ensure every pellet is packed with the right chemical balance.

When we talk about farming at scale, buying fertilizer is only one part of the equation. Many large-scale plantations and agricultural investors are now looking toward manufacturing their own. Why? Because producing your own fertilizer allows for better quality control and significant cost savings over time.

Building a production line might sound complicated, but the process is actually quite logical. The goal is to take raw materials鈥攗sually phosphoric acid and ammonia鈥攁nd turn them into solid, easy-to-spread granules.

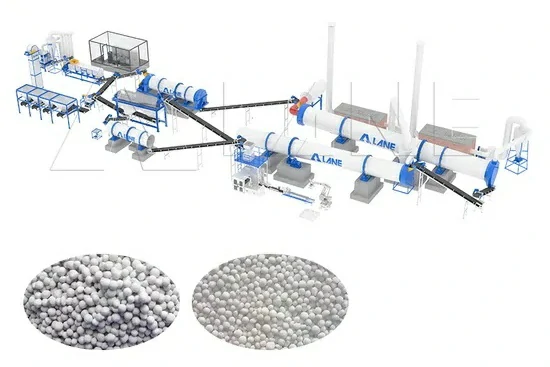

To boost sugarcane yield with high-efficiency DAP fertilizer production line machinery, the process follows a specific flow:

Everything starts in a large vessel called a pipe reactor or a pre-neutralizer. This is where the liquid ammonia and phosphoric acid meet. They react chemically to form a hot, slurry-like substance. This stage is critical because the chemical consistency here determines how effective the final fertilizer will be in the field.

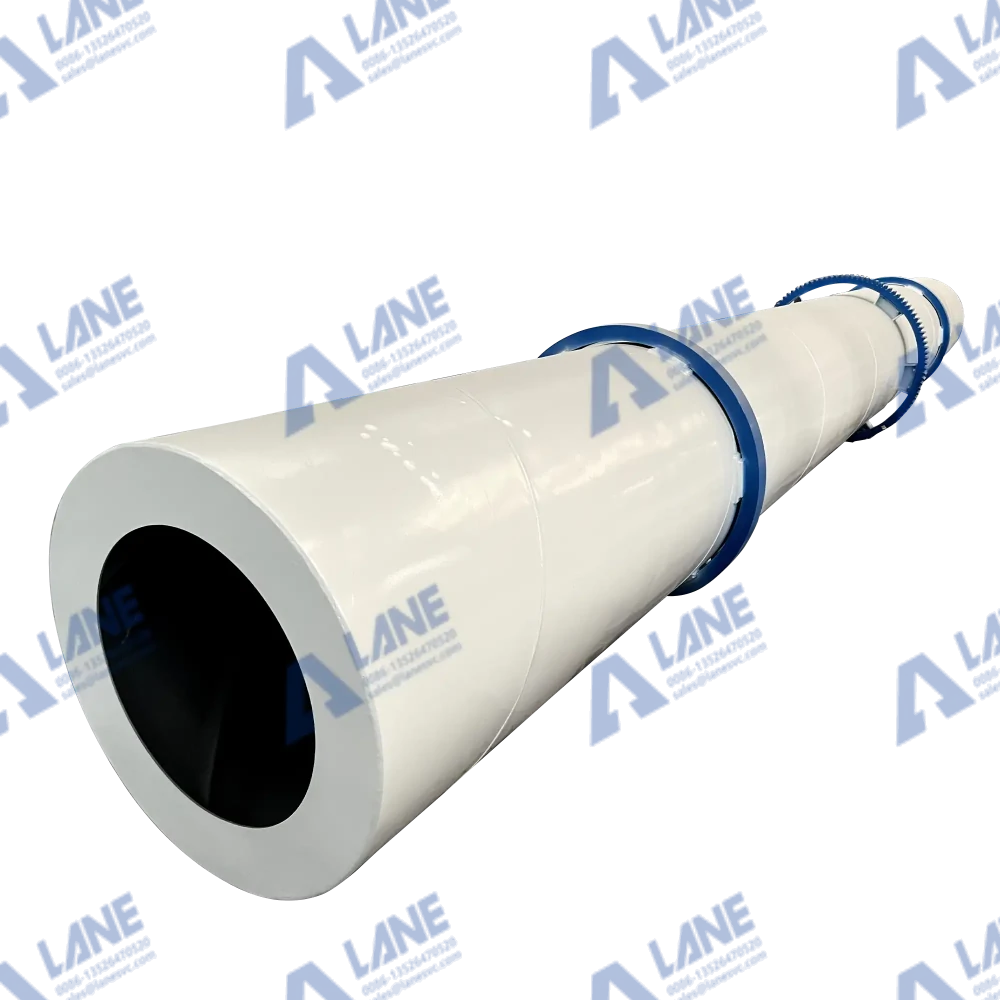

Once the slurry is ready, it moves into a Rotary Drum Granulator. This is a massive, rotating cylinder. As it spins, the slurry is sprayed onto a bed of recycled dry fertilizer particles. The tumbling motion causes the liquid to coat the dry bits, building them up into round granules. This shape is important because round pellets fly better out of a spreader and dissolve evenly in the soil.

The fresh granules are damp and warm. If you bagged them now, they would turn into a giant brick. A rotary dryer uses hot air to remove moisture, and then a cooling machine brings the temperature down. This makes the fertilizer stable for long-term storage.

Not every pellet comes out the perfect size. A rotary screening machine sifts through the batch, sending the “perfect” ones to be coated and the “imperfect” ones back to the start to be remade. Finally, a light coating of oil or wax is often added to prevent the pellets from clumping together in humid tropical climates where sugarcane grows.

If you want to boost sugarcane yield with high-efficiency DAP fertilizer production line technology, you need hardware that can handle the heat and chemical intensity of the process.

Rotary Drum Granulator: The heart of the line. It must be lined with special materials to prevent corrosion from the acidic slurry.

Rotary Dryer and Cooler: These large drums ensure the product is “shelf-ready.”

Crushers and Mixers: Used to prep any solid raw materials and recycle the oversized granules.

Automatic Packaging Machine: Because manual bagging is too slow for a high-efficiency setup.

Using the right machines ensures that the fertilizer doesn’t just look good, but actually performs. When the granules are uniform, the nutrients release into the soil at a steady rate, which is the best way to boost sugarcane yield with high-efficiency DAP fertilizer production line output.

At LANE, we don’t just sell machines; we build the future of your farm. With over 20 years of professional experience in the Chinese fertilizer machinery industry, we have seen every challenge and solved every problem. We have dedicated our careers to helping clients boost sugarcane yield with high-efficiency DAP fertilizer production line installations that stand the test of time.

Customized Engineering

We know that every project is different. Our professional engineering team provides customized services, meaning we design, manufacture, and install the entire production line based on your specific land size and budget. We don鈥檛 believe in “one size fits all.”

One-Stop Service

When you work with us, you get a partner from start to finish. We handle everything from the initial equipment installation to comprehensive after-sales support. This includes regular maintenance, troubleshooting, and even future upgrades. We make sure your line stays running so your crops keep growing.

Quality You Can Trust

Quality is our obsession. Our products meet ISO9001 and CE international quality standards, ensuring that you receive reliable, safe, and durable machinery. We specialize in NPK lines, organic fertilizer equipment, and, of course, the systems needed to boost sugarcane yield with high-efficiency DAP fertilizer production line capabilities.

The Impact on the Field

Imagine a sugarcane field where every plant is the same height, the leaves are a deep, healthy green, and the sugar brix levels are through the roof. This is the reality for producers who invest in their own supply chain. By using a boost sugarcane yield with high-efficiency DAP fertilizer production line approach, you eliminate the guesswork.

You know exactly what is in your fertilizer. You know it was made recently and hasn’t been sitting in a damp warehouse for a year. This freshness and precision lead to better root development and stronger stalks.

To consistently boost sugarcane yield with high-efficiency DAP fertilizer production line results, you have to take care of the machines. Because DAP production involves acids, we build our equipment with high-grade anti-corrosion materials. However, regular check-ups are still vital.

Our team at LANE stays in touch with our clients long after the sale. We provide the spare parts and the technical “know-how” to ensure that your investment continues to boost sugarcane yield with high-efficiency DAP fertilizer production line performance for decades.

The global demand for sugar and ethanol is only going up. To stay competitive, you need to produce more with less. Investing in a professional production line is the most effective way to control your costs and maximize your output.

If you are looking to boost sugarcane yield with high-efficiency DAP fertilizer production line technology, let us help you. We have the experience, the tools, and the team to turn your vision into a high-yielding reality.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.