In recent years, Argentina has continued to strengthen its agricultural production. Crops such as corn, wheat, and soybeans have a strong demand for phosphate fertilizers. Because of this, many customers contact us to ask how to build a 10t/h dap fertilizer production line in Argentina that is efficient, stable, and suitable for local conditions.

From our experience, DAP fertilizer plays an important role in improving soil fertility and crop yield. That is why investing in a local DAP production line is becoming an attractive option for fertilizer producers in Argentina.

Before we help clients build a 10t/h dap fertilizer production line in Argentina, we always begin by studying the local situation. Raw material supply, factory space, climate, and energy costs all affect how the production line should be designed.

Argentina has good access to phosphate-related raw materials and stable industrial infrastructure. Based on these factors, our engineering team designs a practical and flexible layout. We believe that a production line should not only meet today鈥檚 capacity needs, but also allow room for future upgrades.

Many people think fertilizer plants are extremely complicated. In fact, when you build a 10t/h dap fertilizer production line in Argentina, the process follows clear steps, and each machine has a specific function.

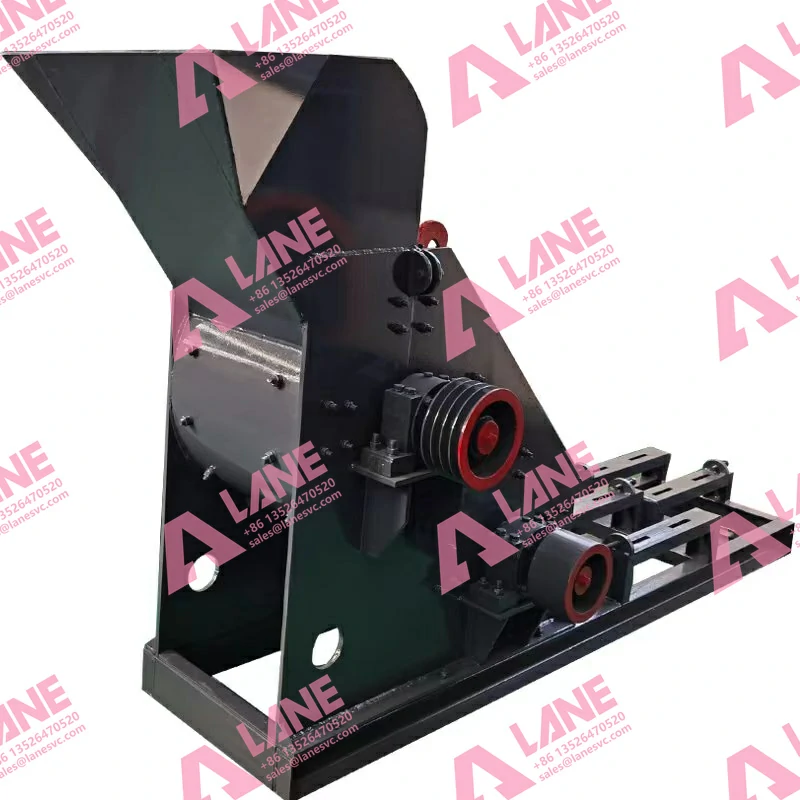

The production line usually starts with a crusher, such as a cage crusher or hammer crusher. This machine is used to crush solid raw materials into fine powder, making them suitable for further processing.

After crushing, materials are transferred to a horizontal mixer. This mixer blends phosphate materials and other additives evenly. Uniform mixing is very important for DAP fertilizer quality, and this step directly affects the final granule strength.

Granulation is the key stage of the whole line. In many projects, we recommend a double roller granulator when customers want to build a 10t/h dap fertilizer production line in Argentina. This machine uses extrusion force to form granules, offering stable output, low energy consumption, and easy maintenance.

Once granules are formed, they enter a rotary drum dryer. The dryer removes excess moisture and improves the hardness of DAP granules. After drying, a rotary drum cooler is used to reduce temperature quickly, which helps prevent caking during storage.

Next, the material passes through a rotary screening machine. Qualified granules move forward, while oversized or undersized particles are returned to the crusher for reprocessing. This recycling system helps reduce raw material waste.

If required, a fertilizer coating machine can be added to the line. This machine improves the appearance of DAP granules and enhances anti-caking performance.

Finally, finished products are packed using an automatic packaging machine. For a project aiming to build a 10t/h dap fertilizer production line in Argentina, automatic packing greatly improves efficiency and reduces labor costs.

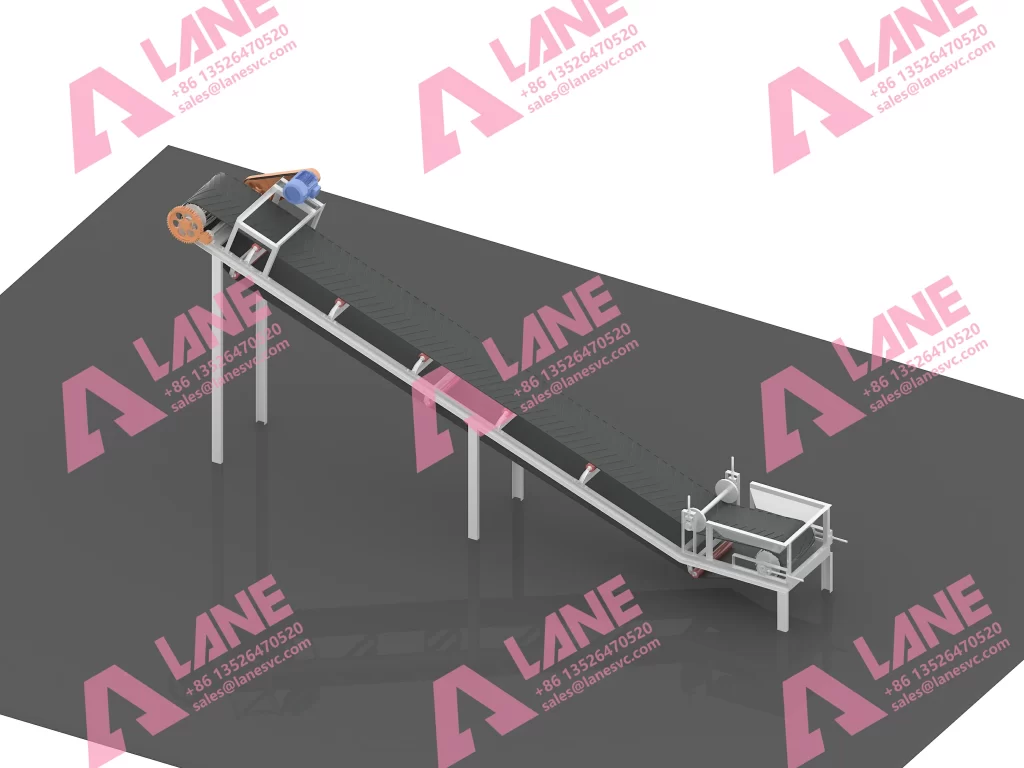

Throughout the line, belt conveyors connect each machine and ensure smooth material flow. We customize conveyor length and layout based on the customer鈥檚 factory space.

Every project is different. That is why we never copy designs. When customers plan to build a 10t/h dap fertilizer production line in Argentina, our engineers provide customized solutions based on raw materials, production targets, and investment budget.

Because we manufacture the equipment ourselves, customization is flexible and practical. This helps customers avoid unnecessary costs and improves overall production efficiency.

High-quality machines still need correct installation. After equipment delivery, our technical team provides guidance for installation and commissioning. For customers who build a 10t/h dap fertilizer production line in Argentina, this support helps shorten the startup period.

We also offer operator training. Our goal is to ensure that local workers understand daily operation and basic maintenance, so the production line can run smoothly.

We believe real service begins after the machines start working. We provide long-term after-sales support, including maintenance guidance, troubleshooting, and technical upgrades. This support is especially important for clients who build a 10t/h dap fertilizer production line in Argentina and want stable, long-term operation.

Our equipment complies with ISO9001 quality management standards and CE certification, ensuring reliability and safety in real production environments.

For over 20 years, we have focused on fertilizer machinery manufacturing. Our main products include fertilizer production lines, DAP and NPK production lines, organic fertilizer equipment, and compound fertilizer systems. This experience allows us to respond quickly and professionally when clients want to build a 10t/h dap fertilizer production line in Argentina.

We provide one-stop service, from equipment design and manufacturing to installation and after-sales support. This saves time, reduces communication costs, and improves project efficiency.

Building a fertilizer plant is a serious investment, but it does not have to be complicated. With clear planning, suitable equipment, and a reliable partner, it is entirely possible to build a 10t/h dap fertilizer production line in Argentina that meets market demand and operates efficiently.

As agriculture continues to develop, DAP fertilizer will remain an important product. We are always ready to support customers who want to turn their ideas into real, working production lines.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.