For anyone following Southeast Asian agriculture, it has become impossible to ignore how often the term DAP fertilizer production line in Indonesia now appears in news updates and investment reports. As the country expands its palm oil plantations, rice fields, maize farms, and large-scale estate crops, the national fertilizer demand is changing faster than ever. DAP, with its high nutrient value and dependable crop performance, is one of the most essential phosphate fertilizers in Indonesia. And behind every bag of DAP granules delivered to farms, there is a highly engineered system turning raw materials into well-shaped, dust-free particles ready for the fields. Understanding how a DAP fertilizer production line in Indonesia operates helps us understand why local producers are now investing heavily in modern equipment.

At first glance, many people imagine a fertilizer factory as a simple mixing operation.

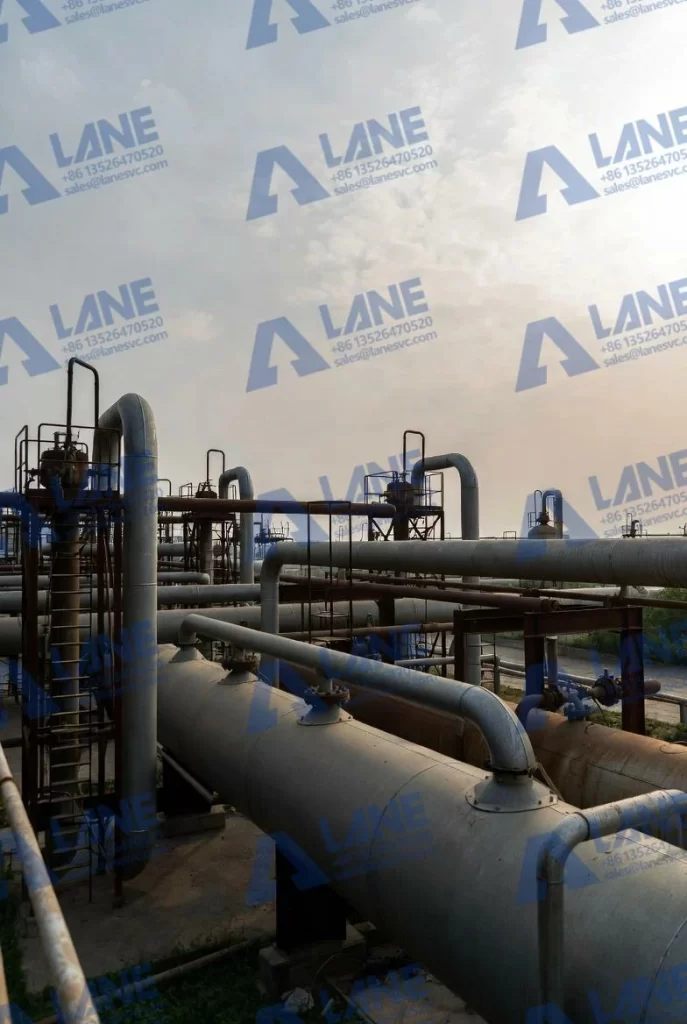

In reality, a DAP fertilizer production line in Indonesia is much closer to a chemical plant than a warehouse. The journey begins with phosphoric acid and liquid ammonia—two reactive ingredients that must be combined under controlled conditions. This reaction releases heat, forms DAP slurry, and sets the foundation for granulation. The level of automation, engineering, and machinery precision in this stage determines both the quality of DAP and the overall efficiency of the whole plant.

Once the chemical reaction is complete, the slurry must be processed quickly while it is still hot and flowing.

This is where the key machinery of a DAP fertilizer production line in Indonesia appears: the ammonia–phosphoric acid reactor, the evaporator, and most importantly, the rotary drum granulator. In mature phosphate fertilizer industries worldwide, the drum granulator is considered the “heart” of DAP production. Indonesia follows the same standard. The granulator blends slurry with recycled material, allowing seeds of granules to grow layer by layer. A well-designed drum ensures uniform rolling, proper spray angles, and stable granule formation. If the drum is engineered correctly, the entire production line becomes easier to operate, with fewer fluctuations in moisture, size, or particle hardness.

Drying is the next critical step. A DAP fertilizer production line in Indonesia typically includes a large rotary-drum-dryer capable of handling high temperatures without burning or deforming the granules. The dryer uses hot air to remove moisture until the particles reach a safe storage level. A poorly controlled drying process can lead to cracked particles or uneven hardness, so temperature management is essential. After drying, the granules move to a rotary cooler, where air circulation reduces temperature and stabilizes the product. Indonesian producers appreciate the reliability of stable dryers and coolers because the country’s tropical climate often brings high humidity, making proper moisture control even more important.

Screening equipment comes next. Every DAP fertilizer production line in Indonesia relies on rotary-screening-machine to classify the granules. Oversized particles return for crushing; undersized granules go back to the drum for further growth. This closed-loop system ensures that only medium-sized, market-ready particles proceed to coating and packaging. Coating machines add an anti-caking layer so that the product stays free-flowing even during Indonesia’s humid rainy season. Finally, fully automated packaging systems weigh, fill, sew, and palletize the fertilizer bags, preparing them for storage or delivery.

While the machinery itself is impressive, what makes a DAP fertilizer production line in Indonesia truly effective is how all components work together. Chemical reaction, granulation, drying, cooling, screening, coating, and packing must flow smoothly. If any part lags—whether it is a pump, a conveyor, or a dryer—the whole line slows down. This is why Indonesian investors prefer suppliers who offer not only equipment but also engineering guidance, layout optimization, and operator training.

Indonesia’s agricultural transformation has pushed fertilizer producers to expand their production capacity quickly. With rising demand from palm oil estates and national rice programs, every efficient DAP fertilizer production line in Indonesia contributes directly to higher food productivity. Farmers require fertilizers that dissolve well, spread evenly, and deliver consistent nutrients. Modern DAP granules meet these needs better than older powdery or low-density fertilizers. For local manufacturers, this means a strong push toward upgrading outdated facilities and adopting global-standard equipment.

Energy efficiency is another factor. Old fertilizer factories often consume excessive heat and electricity, especially in granulation and drying. Modern drums, burners, and evaporators reduce fuel use significantly. When applied across multiple plants, these savings become substantial and help Indonesian producers remain competitive against imported fertilizers. A well-structured DAP fertilizer production line in Indonesia can reduce downtime, cut waste, and deliver cleaner, more uniform granules—all of which support both profitability and environmental goals.

This is where companies like LANE become increasingly important. With more than 20 years specializing in fertilizer machinery manufacturing in China, Our company provides engineering teams capable of designing full fertilizer production lines according to the customer’s exact needs. Many Indonesian investors, especially new entrants to fertilizer processing, appreciate working with suppliers who offer not just machines but a complete solution—from layout design to installation and on-site guidance.

Our company’s equipment meets ISO 9001 and CE quality standards, which is a strong reassurance for producers aiming to build a dependable DAP fertilizer production line in Indonesia. Our expertise covers NPK production, organic fertilizer systems, and compound fertilizer machines, making us a versatile partner for companies planning future expansions. Beyond installation, We provides hands-on after-sales services including maintenance, troubleshooting, and system upgrades. For Indonesian factories operating in humid, high-temperature climates, such support ensures the equipment continues running at peak performance year-round.

As demand grows, Indonesian producers seek partners who can offer stable drum granulators, reliable dryers, corrosion-resistant reactors, and long-lasting coating machines. Our company’s engineering approach focuses on durability and efficiency, helping factories reduce unplanned downtime. These advantages make us a trusted supplier for anyone planning a new DAP fertilizer production line in Indonesia or upgrading an existing one.

Agricultural transformation is ongoing across Indonesia. As more provinces expand plantation crops and maximize yields, modern fertilizers will continue gaining importance. Every new DAP fertilizer production line in Indonesia is more than a business project—it becomes part of the national food-security system. With rising adoption of automation, smarter controls, and better granulation technology, the quality of Indonesian-made DAP is expected to improve steadily in the coming years.

Looking ahead, the country’s fertilizer market is likely to shift toward cleaner production processes, lower emissions, and higher output efficiency. Producers who invest early in well-engineered systems will enjoy long-term advantages, especially as government policies increasingly focus on sustainable agriculture. With capable suppliers like LANE offering technology, installation, and long-term technical support, Indonesia’s fertilizer manufacturing capabilities will continue to mature and expand.

In the end, the story of each DAP fertilizer production line in Indonesia is not only about manufacturing fertilizer—it is about supporting millions of farmers, strengthening national food resilience, and building a more sustainable agricultural future for the entire country.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.