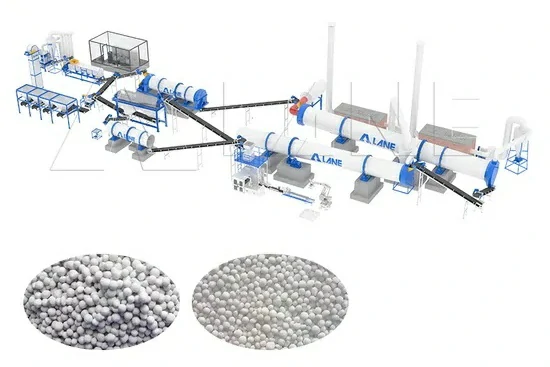

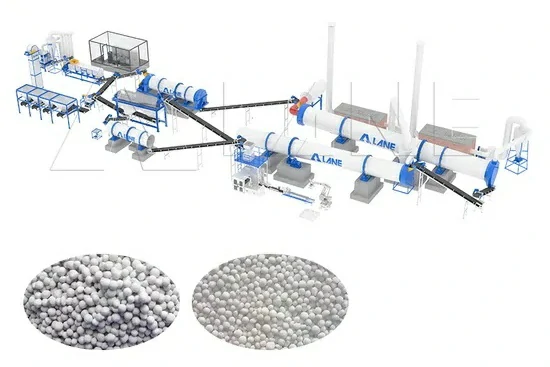

The DAP granulator machine plays a crucial role in the modern fertilizer industry, serving as the heart of Di-Ammonium Phosphate (DAP) fertilizer production. Whether you are operating a large-scale phosphate plant or running a medium-sized fertilizer line, choosing the right DAP fertilizer production line can significantly improve your output quality, reduce energy costs, and ensure product uniformity.

At LANE, we have years of experience designing and supplying complete DAP fertilizer production lines around the world. Our granulation machines are engineered for high efficiency, precision, and long-term reliability βÄî making them an excellent investment for any fertilizer manufacturer aiming to increase profitability and sustainability.

What is a DAP Granulator Machine?

A DAP granulator machine is a specialized equipment used to convert DAP powder or mixed phosphate raw materials into uniform and high-strength particles. The granulation process can enhance the physical properties of DAP fertilizer, improving its handling, transportation, and application efficiency.

In simple terms:

Under controlled conditions of humidity, pressure and temperature, it transforms powdered materials into granules through agglomeration. The final product is granules with good fluidity and no dust, suitable for commercial fertilizer applications.

Working Principle of a DAP Granulator Machine (Expanded Version)

The working principle of a DAP granulator machine revolves around the controlled chemical reaction between ammonia (NHβ²É) and phosphoric acid (Hβ²ÉPOβ²³), followed by the physical agglomeration of the resulting slurry into uniform, solid granules. The machine not only performs mechanical shaping but also facilitates essential thermal and chemical transformations that determine the final quality of DAP fertilizer.

1.Chemical Reaction and Slurry Formation

At the beginning of the process, liquid ammonia and phosphoric acid are precisely metered and introduced into the granulator through separate feed lines. Inside the machine, the two react exothermically to produce di-ammonium phosphate (NHβ²³)β²²HPOβ²³.

This reaction releases heat, which partially evaporates water, creating a semi-moist DAP slurry that becomes the basis for granulation. The temperature inside the DAP granulator machine typically ranges from 80¬ΑC to 105¬ΑC, which helps in maintaining proper slurry viscosity and adhesion properties.

2.Granule Nucleation and Growth

The moist slurry begins to attach to small nuclei (seed particles or recycled fines) present in the granulator. As the machine rotatesβÄîwhether in a drum, disc, or roller configurationβÄîthese particles collide, roll, and stick together layer by layer, gradually forming spherical granules.

The rotation speed, drum inclination angle, and residence time are all key control parameters that influence granule size and uniformity. For example:

Higher rotation speed βÜ£ smaller, denser granules.

Lower speed βÜ£ larger, more porous granules.

Controlled moisture (8βÄ™12%) ensures proper binding without over-wetting.

This mechanical action, combined with heat and chemical reaction, ensures that granules are dense, strong, and uniformly sized, which is critical for storage and application performance.

3.Internal Airflow and Ammonia Distribution

Modern DAP granulator machines are designed with internal airflow systems that help distribute ammonia evenly throughout the chamber. This ensures complete chemical conversion and prevents the formation of acidic or alkaline zones inside the drum. Proper ammonia distribution is essential to achieve a neutral pH (around 7.5βÄ™8.0) in the final product, which improves fertilizer stability.

Additionally, an exhaust gas system removes excess moisture and reaction gases, keeping the working environment clean and reducing energy loss in the drying stage.

4.Granule Discharge and Recycling

Once the granules reach the target sizeβÄîusually between 2βÄ™4 mmβÄîthey are discharged through the outlet port. Oversized and undersized granules, separated later by the screening system, are crushed and recycled back into the granulator to serve as seed materials for new granules. This closed-loop granulation cycle ensures consistent product quality and minimizes raw material waste.

5.Integration with Downstream Equipment

The DAP granulation process doesnβÄôt end inside the granulator. The machine works in synchronization with dryers, coolers, and screeners to achieve the desired final moisture (below 2%) and particle hardness. The granules leaving the granulator are often at 8βÄ™10% moisture and need to be dried at 110βÄ™130¬ΑC before cooling. LANEβÄôs automated control systems link these steps together for seamless and energy-efficient operation.

Main Types of DAP Granulator Machines

Different granulation technologies serve different production needs. Below are the most common types of DAP granulator machines:

| Type | Working Principle | Advantages | Typical Capacity |

| Rotary Drum Granulator | Rotating drum promotes agglomeration by tumbling action | High capacity, low dust, ideal for large-scale DAP production | 3βÄ™30 t/h |

| Disc (Pan) Granulator | Raw materials roll on the inclined disc to form granules | Simple structure, easy to operate, suitable for medium-scale production | 1βÄ™6 t/h |

| Double Roller Extrusion Granulator | Materials are compacted by high-pressure rollers | No drying needed, energy-saving, suitable for small to medium DAP plants | 0.5βÄ™3 t/h |

At LANE, we provide all these types of granulators depending on customer needs. Our team helps assess your raw materials, desired capacity, and local environmental requirements before recommending the most suitable DAP granulator machine.

Investing in a reliable DAP granulator machine is one of the most effective ways to ensure stable, high-quality fertilizer production. From boosting yield to improving sustainability, the right granulation system can redefine your entire production process.

With LANEβÄôs advanced technology, customized solutions, and full-service support, your DAP production will achieve higher efficiency, lower cost, and superior granule quality βÄî ready to meet the growing global demand for phosphate-based fertilizers.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.