Fertilizer production is evolving, and energy saving DAP fertilizer manufacturing has become a key focus for modern agricultural businesses. At our company, we understand that saving energy while producing high-quality DAP (diammonium phosphate) fertilizer is essential for both cost efficiency and environmental responsibility. In this article, we will explore how energy saving DAP fertilizer manufacturing works, the types of equipment involved, and how our team at LANE can provide complete solutions for fertilizer production.

Energy saving DAP fertilizer manufacturing is all about optimizing the production process to reduce energy use without sacrificing quality. DAP fertilizer is a widely used source of phosphorus and nitrogen for crops, and producing it efficiently requires careful planning and the right machinery. By focusing on energy saving DAP fertilizer manufacturing, companies can reduce operating costs, lower carbon emissions, and improve sustainability in their operations.

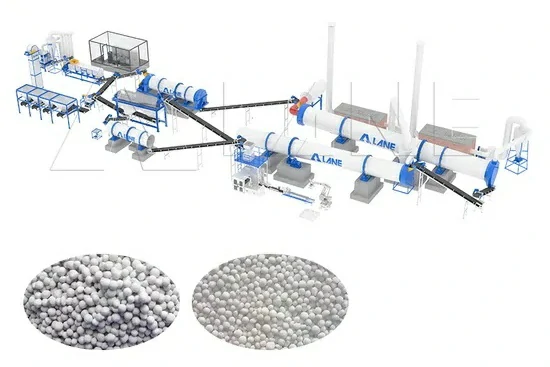

The production of DAP fertilizer involves several steps, including raw material mixing, granulation, drying, cooling, screening, and packaging. Each step requires specialized equipment to ensure efficiency and consistent product quality.

To achieve successful energy saving DAP fertilizer manufacturing, certain equipment plays crucial roles in the DAP production line.

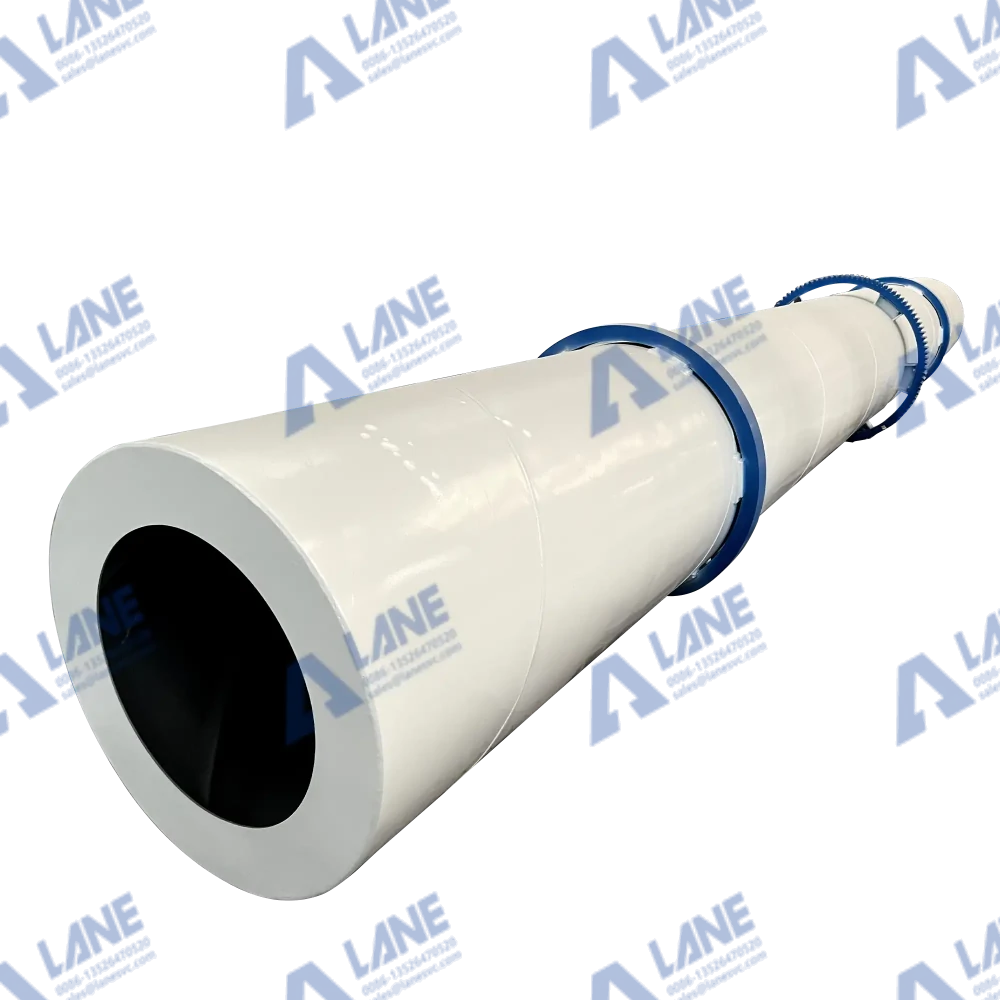

The first step in DAP fertilizer production is mixing raw materials like phosphoric acid and ammonia. Our batching and mixing machines are designed to handle materials efficiently, ensuring a consistent chemical composition for high-quality DAP. The double screw cone mixer is essential for energy saving DAP fertilizer manufacturing because it reduces the need for repeated processing, saving both energy and time.

Granulation is the heart of DAP fertilizer production. Our granulators transform raw materials into uniform granules. Using advanced technology, these machines are designed for energy saving DAP fertilizer manufacturing by reducing power consumption while maintaining high output. Uniform granules also improve fertilizer storage and application efficiency.

After granulation, DAP fertilizer needs drying and cooling. Energy saving dryers and coolers help maintain product quality while minimizing energy use. Our company provides equipment with optimized airflow and heating systems to ensure fast drying and efficient cooling, which is a key part of energy saving DAP fertilizer manufacturing.

Once cooled, the fertilizer is screened to separate fines from qualified granules. Proper screening ensures a consistent product size, which improves fertilizer effectiveness in the field. Our automatic packaging machines then efficiently pack the fertilizer, ready for transport. These machines are designed to support energy saving DAP fertilizer manufacturing by minimizing energy waste and operational time.

At LANE, we have over 20 years of experience in the Chinese fertilizer machinery industry, specializing in energy saving DAP fertilizer manufacturing. Our professional engineering team can design and manufacture custom equipment according to your specific needs.

We provide complete solutions—from equipment installation to full-scale production line support. Our services include maintenance, troubleshooting, and system upgrades, ensuring that your DAP fertilizer production line operates efficiently and continuously.

Our products meet international quality standards such as ISO9001 and CE, giving you confidence in reliability and performance. LANE’s core strength lies in providing machinery for organic, compound, and liquid fertilizers. Whether you need a small-scale setup or a fully automated production line, we deliver comprehensive solutions tailored to your requirements.

Monitor Energy Consumption – Keep track of electricity and fuel usage in your production line to identify opportunities for improvement.

Regular Equipment Maintenance – Proper maintenance reduces energy waste and extends equipment life.

Process Optimization – Adjust temperature, granulation speed, and material flow to reduce energy consumption without compromising quality.

Automation and Control Systems – Automated control systems can optimize energy use by adjusting machine operation according to real-time conditions.

By implementing these practices and using LANE’s high-quality, efficient equipment, companies can maximize the benefits of energy saving DAP fertilizer manufacturing.

Energy saving DAP fertilizer manufacturing is not just about reducing costs—it is about creating sustainable solutions for agriculture. As the global demand for fertilizers grows, efficient production methods are increasingly important. Our company is committed to innovation, helping clients achieve high productivity while reducing energy consumption and environmental impact.

With LANE’s professional engineering team, we can provide complete solutions for any scale of fertilizer production. From equipment design to installation and ongoing support, we ensure that your energy saving DAP fertilizer manufacturing process is smooth, efficient, and reliable.

Energy saving DAP fertilizer manufacturing is essential for modern agriculture. By using the right equipment, optimizing processes, and partnering with a professional company like LANE, businesses can produce high-quality DAP fertilizer efficiently and sustainably.

Our 20+ years of experience, custom engineering capabilities, comprehensive service, and adherence to ISO9001 and CE standards make us a trusted partner for fertilizer manufacturers worldwide. From granulators and dryers to packaging machines and full production lines, LANE provides everything you need to succeed in energy saving DAP fertilizer manufacturing.

Invest in the right machinery, optimize your processes, and let us help you make your DAP fertilizer production more efficient, cost-effective, and environmentally friendly.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.