When it comes to granule size control in DAP fertilizer, many people think it’s complicated. But the truth is, with the right approach, controlling particle size can be surprisingly straightforward. The size of DAP fertilizer granules affects not only field application but also packaging, transport, storage, and overall market value. Too large granules may break during transport, while too small granules may create dust and uneven application. In this article, we’ll explore how three key machines—the granulator, screening machine, and rounding machine—work together to produce DAP fertilizer with ideal particle sizes and high qualified rates, making production both efficient and cost-effective.

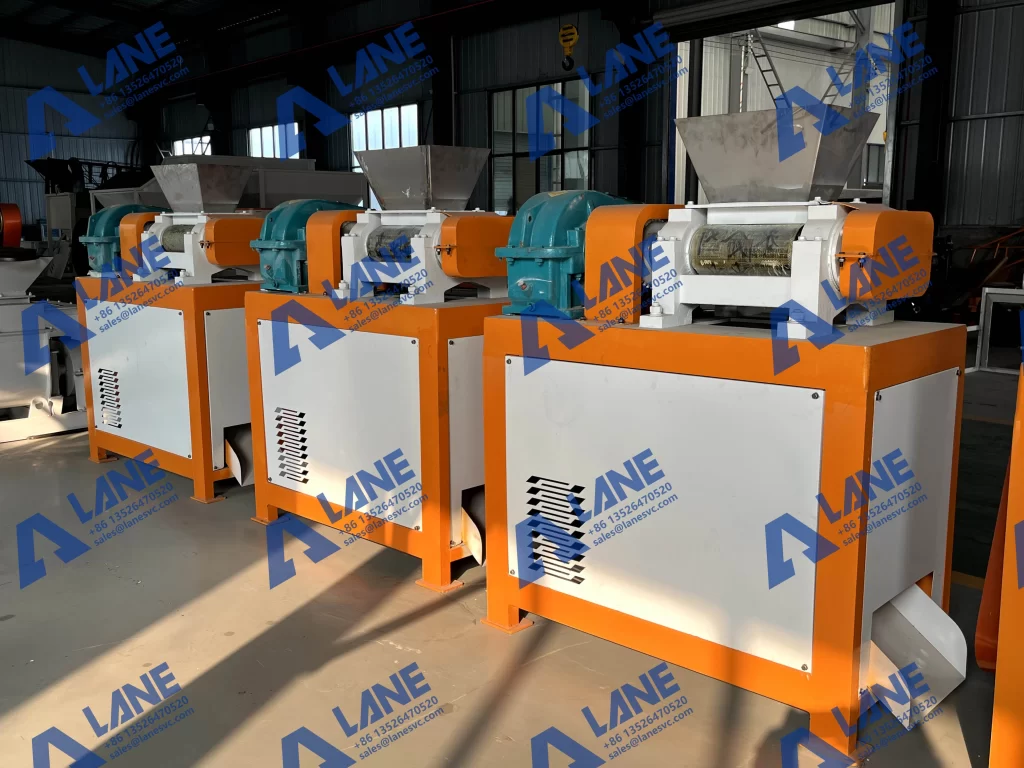

The first stage of granule size control in DAP fertilizer begins at the granulator. This is where powdery DAP begins to take shape as small particles. Among the most common types, double-roller granulators are preferred because they allow precise adjustment of particle size through mechanical compression, which is ideal for DAP fertilizer’s hardness and crystalline properties.

Roll gap: The distance between the rollers is one of the most critical factors. A smaller gap increases compression, giving particles more time to stick together, producing larger granules. Conversely, a larger gap reduces compression time, resulting in smaller granules. Fine-tuning the roll gap by even a fraction of a millimeter can make a significant difference in granule size uniformity.

Material moisture: Moisture content needs to be just right. Too dry, and particles crumble; too wet, and they stick together excessively or clog the rollers. Regularly monitoring moisture content ensures consistent granule formation.

Roller speed: The speed of the rollers affects granule uniformity. Moderate speed helps achieve evenly sized granules, while excessive speed can cause granules to crack or break before reaching the desired size.

Practical tip: Many production lines implement real-time monitoring systems to measure granule size distribution immediately after the granulator. This allows operators to adjust roller gaps, speed, or moisture content instantly, maintaining a stable production process.

The granulator doesn’t just create the initial size—it also sets the foundation for downstream machines. A well-controlled granulation process reduces the workload for screening and rounding machines, improving overall efficiency and reducing waste.

After granulation, DAP particles move to the vibrating screening machine, where granule size control in DAP fertilizer becomes more precise. The screening machine’s main job is to separate particles by size and remove any that are outside the desired range. This step is crucial because uneven particle size affects not only the appearance and handling of the fertilizer but also its application in the field.

Factors influencing granule size during screening include:

Screen mesh size: The mesh must match the target granule size. Smaller meshes retain larger particles while letting smaller ones pass. Choosing the right mesh size ensures that oversized granules can be redirected back to the granulator or rounded for refinement.

Vibration frequency and angle: Proper vibration ensures that particles move smoothly across the screen. Incorrect vibration can lead to blocking, over-screening, or under-screening, all of which affect particle uniformity.

Feed rate: Feeding too much material at once can overload the screen, causing uneven separation. Operators often regulate feed rates in combination with screen vibration to maintain a steady flow.

Case example: In a mid-sized fertilizer plant, adjusting the vibration frequency by just 5 Hz improved the proportion of correctly sized DAP granules from 88% to 93%. It shows how minor adjustments in the screening stage can significantly enhance granule size control in DAP fertilizer.

Screening also serves as a quality checkpoint. Oversized particles can be crushed or returned to the granulator, while undersized particles can be sent to the rounding machine for further processing. This feedback loop ensures that the final product is uniform and meets customer expectations.

The final stage in granule size control in DAP fertilizer is the polishing machine. After screening, particles may have rough edges or irregular shapes. The polishing machine polishes the granules, making them more spherical, which not only improves appearance but also increases handling durability and reduces breakage during transport.

Key parameters include:

Rotation speed and processing time: A higher rotation speed or longer processing time allows smaller particles to merge slightly and smooth edges, slightly increasing average granule size. Shorter times maintain the initial granule size but may leave sharp edges.

Material load and layer thickness: Overloading the rounding drum can cause excessive friction, breaking some particles, while too thin a layer may result in inefficient rounding. Operators must balance load for optimal granule quality.

Particle contact dynamics: Proper mixing ensures that particles continuously collide and roll against each other, which naturally polishes the surfaces and adjusts minor size differences.

Practical tip: Many modern DAP fertilizer plants use automated sensors in rounding machines to track particle size in real time. This allows operators to adjust speed and load to keep the final granules within specification, ensuring a high qualified rate.

By carefully adjusting these parameters, producers can significantly improve the granule size control in DAP fertilizer, producing smoother, more uniform, and higher-quality particles.

For maximum efficiency, DAP fertilizer production should use an integrated approach:

Granulator(Double roller): Sets the initial particle size and uniformity.

Screening machine: Filters out undersized and oversized granules, ensuring uniform feed to the rounding stage.

Polishing machine: Polishes granules and fine-tunes size and shape, increasing the final qualified rate.

When combined, these three machines allow fertilizer producers to maintain a qualified granule rate above 95%, reducing waste and improving product performance.

At LANE, we specialize in manufacturing fertilizer machinery in China for over 20 years. Our company has a professional engineering team capable of designing, manufacturing, and installing complete DAP fertilizer production lines tailored to your needs. We provide full-scale services, from installation to after-sales support, including maintenance, troubleshooting, and upgrades. With LANE, your production line operates efficiently and consistently, meeting ISO9001 and CE quality standards. We are committed to helping clients achieve optimal granule size control in DAP fertilizer, ensuring high-quality output and smooth operations.

Granule size control in DAP fertilizer is essential for consistent quality, efficient production, and customer satisfaction. By carefully adjusting the granulator, screening machine, and rounding machine, producers can optimize particle size, improve roundness, and achieve a high qualified rate. With the expertise and support from LANE, managing a DAP fertilizer production line becomes simple, reliable, and efficient.

Investing attention in these three machines not only improves product quality but also enhances operational efficiency and reduces waste, making granule size control in DAP fertilizer a practical and achievable goal for any fertilizer plant.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.