Have you ever looked at a sprawling cornfield and wondered what makes those plants grow so tall and green? Often, the secret is a high-quality fertilizer known as DAP. To create this essential nutrient source, one must master the industrial production process of Diammonium Phosphate. It is a journey that combines complex chemistry with heavy-duty mechanical engineering.

At our company, we have spent more than 20 years focusing on the Chinese fertilizer machinery manufacturing sector. We don’t just build machines; we design the heartbeat of agricultural success. For us, the industrial production process of Diammonium Phosphate is an art form that we have perfected over two decades of dedicated industry experience.

The basic chemistry of DAP involves the reaction between phosphoric acid and ammonia. However, the real challenge lies in scaling this up for a global market. The industrial production process of Diammonium Phosphate must be stable, efficient, and cost-effective.

The Reaction Stage: Pre-Neutralizer and Pipe Reactor

Everything begins with the neutralization reaction. In a professional industrial production process of Diammonium Phosphate, we use specialized stainless steel pre-neutralizers or pipe reactors. These vessels handle the high temperatures generated when ammonia meets phosphoric acid. Our engineering team uses acid-resistant materials to ensure these components last for years, even under the most corrosive conditions.

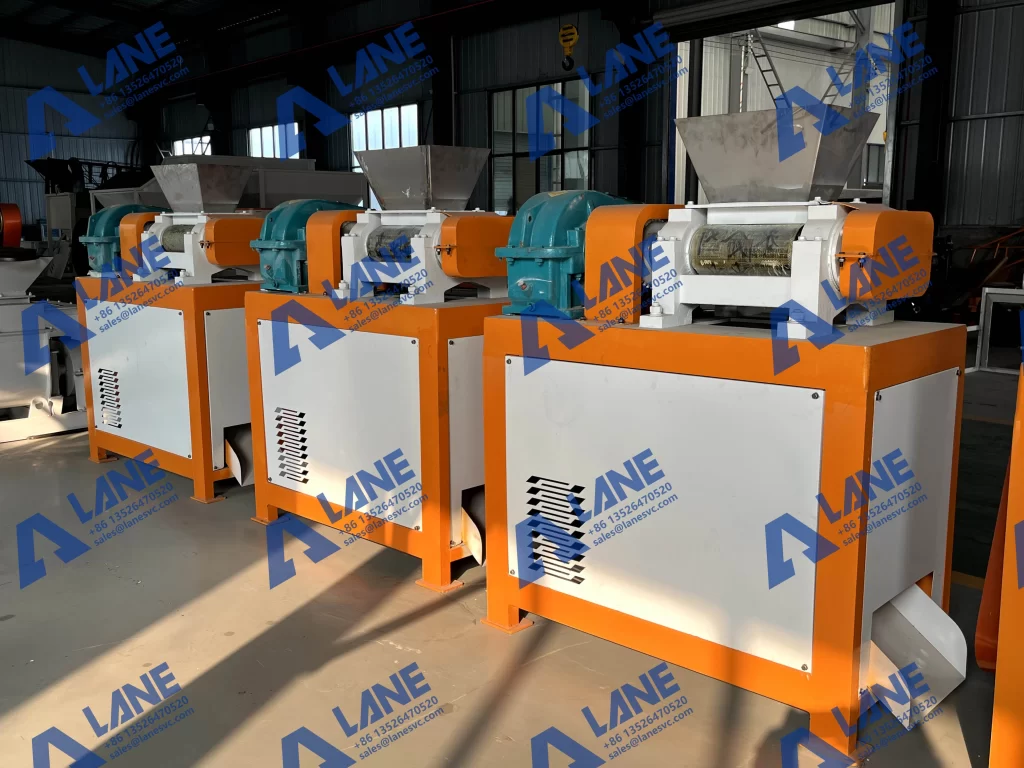

The Heart of the Line: Double Roller Extrusion Granulator

While traditional methods often use rotary drums, many modern facilities are shifting toward the Double Roller Extrusion Granulator for specific DAP formulations. This machine is a game-changer in the industrial production process of Diammonium Phosphate.

Why do we recommend the double roller granulator?

No Drying Required: This is a dry-type granulation process. Because it uses mechanical pressure to form granules, you save a massive amount of energy that would otherwise be spent on large drying furnaces. This is a massive leap forward in the industrial production process of Diammonium Phosphate.

High Strength: The rollers exert immense pressure, creating DAP granules that are incredibly hard and resistant to breaking during transport.

Room Temperature Operation: It simplifies the industrial production process of Diammonium Phosphate by operating at ambient temperatures, reducing the thermal stress on your factory environment.

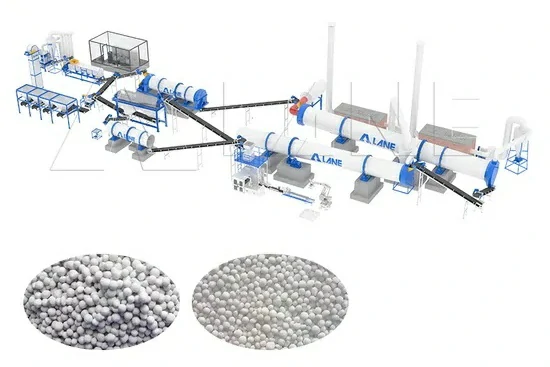

Supporting Machinery: Belt conveyors and Crushers

To keep the industrial production process of Diammonium Phosphate moving, we utilize heavy-duty belt conveyors to transport materials between stages. If any granules don’t meet the size requirements, our Chain Crushers quickly break them down so they can be re-processed. This “closed-loop” system ensures that there is zero waste in your production cycle.

In a modern facility, the industrial production process of Diammonium Phosphate doesn’t end with granulation. To ensure the final product is marketable, we integrate advanced cooling and screening systems. Our Rotary Cooling Machines reduce the temperature of the granules immediately after extrusion, which prevents the DAP from clumping during storage.

Furthermore, the precision of the industrial production process of Diammonium Phosphate is maintained by our high-frequency vibrating screeners. These screens ensure that only granules within the 2mm to 4mm range reach the packaging station. By maintaining such strict control over the physical properties of the fertilizer, we help our clients build a brand reputation for quality and reliability in the global marketplace.

Building a factory for the industrial production process of Diammonium Phosphate is a major investment. You need a partner who understands every bolt and every chemical reaction.

20+ Years of Professional Experience

We have been a pillar of the fertilizer machinery industry for over 20 years. This deep history means we have encountered every possible challenge in the industrial production process of Diammonium Phosphate. We bring this wealth of knowledge to every project, ensuring you avoid common pitfalls and achieve peak production quickly.

Professional Engineering & Customization

We know that no two fertilizer plants are the same. Our professional engineering team works closely with you to design, manufacture, and install complete production lines tailored to your specific site. Whether you need a compact layout or a massive high-capacity system, we customize the industrial production process of Diammonium Phosphate to fit your goals.

One-Stop Full-Scale Service

We believe in supporting our customers from day one until year ten and beyond. Our “One-Stop” service includes:

Expert Installation: We handle the setup to ensure every machine is calibrated perfectly.

Comprehensive After-Sales: We provide maintenance, troubleshooting, and even system upgrades.

Stable Operation: Our goal is to ensure your industrial production process of Diammonium Phosphate line runs efficiently and without unexpected downtime.

International Quality Standards

Reliability is our hallmark. All our equipment—from our NPK production lines to our organic fertilizer machines—complies with ISO9001 and CE international quality standards. When you partner with us, you are investing in world-class quality that stands the test of time.

While we are experts in the industrial production process of Diammonium Phosphate, our capabilities extend across the entire fertilizer industry. We take pride in offering:

Complete Fertilizer Production Lines: Tailored for NPK and compound fertilizers.

Organic Fertilizer Equipment: Helping you turn waste into valuable agricultural products.

Specialized Granulation Systems: Including our signature double roller and rotary drum options.

The world’s demand for food is only growing, and the industrial production process of Diammonium Phosphate remains at the center of meeting that demand. By utilizing our advanced double roller granulation technology and our 20 years of manufacturing excellence, you can produce the high-quality nutrients that farmers need to succeed.

We are committed to being more than just a supplier; we want to be your long-term partner in the fertilizer industry. Let us help you optimize your industrial production process of Diammonium Phosphate with the precision and professionalism you deserve. With our help, the industrial production process of Diammonium Phosphate can become the most profitable and stable part of your business.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.