If you are in the agricultural industry, you know that fertilizer costs can be a real headache. Lately, many farmers and business owners are looking for a way to take control of their supply. That is why we are seeing a huge trend toward installing a low cost MAP fertilizer making machine to produce high-quality nutrients right on-site. It is an exciting time to modernize and save money while boosting your crop yields through self-sufficiency!

Have you ever looked at the price of Monoammonium Phosphate (MAP) and wondered why it’s so expensive? Most of that cost comes from logistics, packaging, and middleman markups. By investing in a low cost MAP fertilizer making machine, small to medium enterprises can produce professional-grade granules without the massive industrial price tag.

But how does it actually work? It isn’t just one single box. It is a synchronized team of specific machines working together. Let’s dive into the heart of the production line and look at the actual machines you will need to get the job done right.

Before we can make those neat little granules, we have to make sure the raw materials are uniform. If your raw phosphate components have large lumps, your final product will be uneven. The Cage Crusher is the most reliable low cost MAP fertilizer making machine component for this initial task.

Operating Principle: This machine uses high-speed rotating cages with heavy-duty steel bars to smash large clumps into a fine powder through high-impact force.

Adjustment Method: You can adjust the rotation speed of the cages to control how fine the output is, depending on your raw material hardness.

Safety & Care: Always check for “tramp metal” (like stray bolts) before starting. Metal can ruin the internal bars and cause vibration issues!

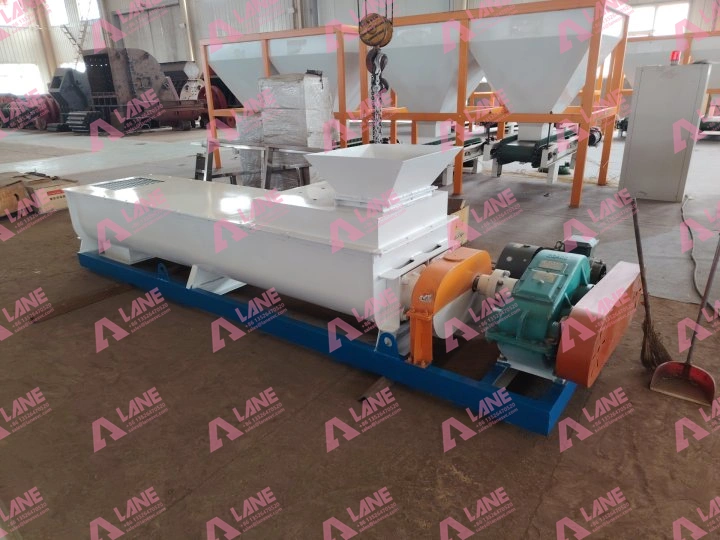

In a low cost MAP fertilizer making machine setup, the double-shaft mixer is where the formula becomes consistent. You need an even distribution of nitrogen and phosphorus to ensure every granule is effective.

Operating Principle: It uses two parallel shafts with paddles that spin in opposite directions. This creates a “weightless” zone where the materials are folded together perfectly within seconds.

Adjustment Method: You can control the mixing time via a digital timer and adjust the paddle angles to change the flow speed through the machine.

Safety & Care: Don’t start the mixer under a full load. It’s better to start the motor first and then add the material to prevent unnecessary strain on the belts and motor.

This is the star of the show. This is the specific low cost MAP fertilizer making machine component that turns loose powder into those familiar round, hard pellets that farmers love.

Operating Principle: Through a combination of moisture (steam or water) and centrifugal force, the powder rolls into small balls as the drum rotates. It’s like rolling a snowball down a hill!

Adjustment Method: You can change the tilt angle of the long drum and the speed of rotation. A steeper angle usually means the material stays in the drum for a shorter time, resulting in smaller granules.

Safety & Care: Keeping the internal rubber liner or scraper clean is vital. If material builds up on the walls, the granules will lose their round shape and become lumpy.

Fresh granules are soft and damp. If you bag them immediately, they will turn into a giant brick in the warehouse. The rotary dryer and cooler are essential parts of any low cost MAP fertilizer making machine line.

Operating Principle: The Dryer uses a hot blast stove to pull moisture out of the MAP granules, and the Cooler uses a large fan to bring them down to room temperature.

Adjustment Method: You can regulate the burner temperature. For MAP, you don’t want it too hot, or you might damage the chemical stability of the fertilizer.

Safety & Care: Regularly check the exhaust fans and dust collectors. Good airflow is the secret to a dry, stable fertilizer that doesn’t clump.

Not every pellet comes out the perfect size. The rotary screening machine ensures only the best ones make it to the customer, making your low cost MAP fertilizer making machine output look professional.

Operating Principle: It uses a rotating cylindrical mesh to sort the granules. Small dust falls through first, then the “good” granules, while oversized lumps exit at the far end.

Adjustment Method: You can swap out the mesh screens depending on whether you want “fine” or “standard” sized pellets for your specific market.

Safety & Care: If the screen gets clogged, use the built-in cleaning brushes to keep the holes open.

The final step is getting the product ready for sale and transport.

Operating Principle: It uses a computer-controlled scale to weigh the MAP fertilizer precisely and drop it into bags, which are then automatically sewn shut.

Adjustment Method: Simply type the target weight (e.g., 25kg or 50kg) into the PLC touch screen interface.

Safety & Care: Keep the sensors clean. Dust buildup can make the scale give inaccurate readings, leading to wasted product.

Specializing as a manufacturer of fertilizer machinery in China for more than 20 years, we have a professional engineering team that can design, manufacture equipment, and handle the installation of whole fertilizer production lines according to your requests. As a trusted supplier of fertilizer equipment, we pride ourselves on providing full-scale services—from the initial installation of your low cost MAP fertilizer making machine to comprehensive after-sales support.

Whether it’s maintenance, troubleshooting, or upgrades, we are always here to ensure your production line operates at its best. Our quality standards meet the ISO9001 and CE international quality standards, so you know you are getting world-class hardware. We are especially good at providing complete fertilizer production lines, NPK production lines, organic fertilizer machines, and compound fertilizer machines.

When you work with us, you aren’t just buying a low cost MAP fertilizer making machine; you are buying two decades of expertise. We understand that every factory is different, and our company is dedicated to tailoring the equipment to fit your specific space and budget.

When you operate a low cost MAP fertilizer making machine line from LANE, the workflow is seamless. Because we design the entire system, every machine “talks” to the next. The Cage Mill feeds the Mixer, which feeds the Granulator, and so on. This integration reduces waste and significantly saves electricity.

Because it is a low cost MAP fertilizer making machine line, the energy consumption is kept to a minimum, and the maintenance is simple enough for a small crew to handle. You don’t need a PhD in engineering to run our equipment; we provide training for your staff to make sure they are comfortable with every lever and screen.

Choosing a low cost MAP fertilizer making machine is about more than just the price tag; it’s about reliability. You want a machine that won’t break down in the middle of the peak planting season. That is why we focus so much on the thickness of the steel and the quality of the motors.

By producing your own MAP, you aren’t just saving money—you are ensuring the quality of the nutrients going into the soil. You know exactly what’s in every bag because you made it yourself! With our 20 years of experience, we can help you achieve that independence.

In today’s economy, being self-sufficient is the best strategy. A low cost MAP fertilizer making machine is the key to unlocking that independence for many agricultural businesses. With the right specific equipment—like our Rotary Drum Granulators and Double-Shaft Mixers—and a professional partner like us at LANE, you can produce high-quality fertilizer that rivals the big industrial brands.

It’s time to stop overpaying for expensive fertilizers and start building your own success. Our team is ready to help you every step of the way, from the first drawing to the first bag of granules. Let us help you grow!

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.