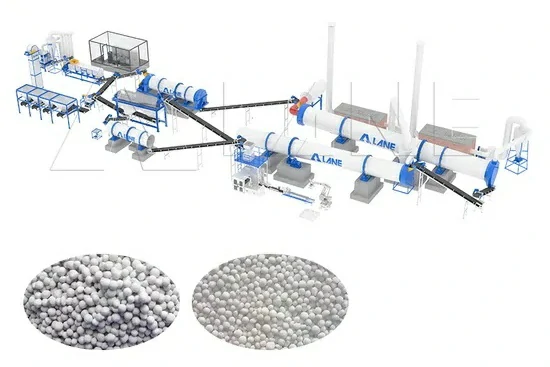

Producing MAP (Monoammonium Phosphate) fertilizer requires specialized granulators. These machines turn raw powder into uniform granules, which are essential for fertilizer quality. Proper maintenance is crucial. Following maintenance tips for MAP Granulator helps prevent breakdowns, improve granule consistency, and extend machine life.

Different types of MAP granulators—rotary drum, disc, and double-roller—operate differently, so their maintenance methods also vary. Understanding the right care for each machine ensures smooth production, energy efficiency, and consistent granule quality. In this article, we’ll cover each granulator type, highlight key maintenance practices, and explain why these practices are important.

Rotary Drum granulators are large rotating cylinders widely used in large-scale MAP production. Raw materials are fed into the drum, and rotation allows them to roll and clump into granules. Rotary  Rotary Drum granulators are favored for their high capacity and ability to produce uniform granules.

Maintenance tips for rotary drum granulator include:

Regular cleaning of the drum shell: Sticky MAP powder can adhere to the inner surface, affecting granule uniformity and increasing the motor load. Cleaning after each shift prevents buildup and keeps granule quality consistent. A soft brush or scraper is usually sufficient, avoiding excess water that could cause corrosion.

Inspect bearings and support rollers: The heavy drum rotates continuously, so worn bearings can cause misalignment, vibration, and uneven granules. Operators should check bearings weekly, listen for abnormal noise, and replace worn parts promptly.

Lubricate bearings and gears: Proper lubrication reduces friction and prevents overheating. Using clean oil or grease at recommended intervals is one of the most effective maintenance tips for MAP Granulator.

Check motor and gearbox: Overheating or unusual sounds often indicate a developing problem. Early detection prevents unexpected downtime.

Tighten bolts and fasteners: Constant rotation can loosen bolts, which may lead to structural misalignment or vibration. Checking and tightening all fasteners regularly protects both the machine and operators.

Extra tip: Rotary drum granulators may also benefit from periodic alignment checks of the entire drum structure to ensure the shell rotates evenly. Small deviations can reduce granule uniformity and increase wear on support rollers.

Disc granulators, or pan granulators, have a round, slightly inclined pan. Materials are fed into the disc while it rotates, forming granules as the material moves along the disc surface. Disc granulators are ideal for small to medium-scale MAP production and allow flexibility in controlling granule size by adjusting disc speed and tilt angle.

Maintenance tips for disc granulators include:

Clean the disc and scraper blades: Sticky MAP material can accumulate on the disc surface and scrapers, reducing granule quality. Clean after every shift to avoid material buildup.

Inspect rotation motor, gearbox, and bearings: Look for wear, unusual sounds, or vibration. Any irregularity may affect granule size and uniformity.

Check disc tilt and rotation speed: Small adjustments ensure proper granule formation. Incorrect tilt or speed can produce irregular or broken granules.

Lubricate all moving parts: Bearings and gears require regular lubrication to reduce wear.

Tighten bolts and fasteners: Even minor vibrations can loosen components. Regular checks prevent misalignment.

Extra tip: The friction between the disc and material is higher than in rotary drum granulators, so scrapers and liners wear faster. Operators should keep spare parts on hand for quick replacement. Following these maintenance tips for MAP Granulator ensures smooth disc operation and consistent granule quality.

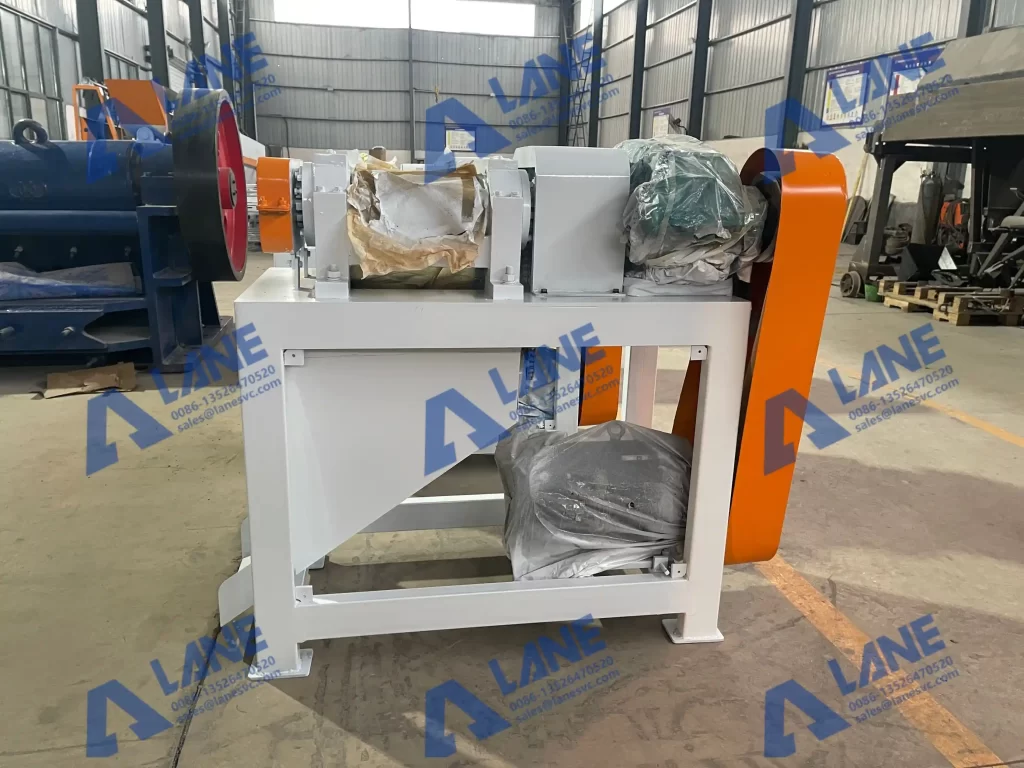

Double-roller granulators use two counter-rotating rollers to compress MAP powder into granules. This produces dense, high-quality granules with minimal dust. Double-roller granulators are efficient and energy-saving, increasingly used in modern MAP fertilizer production.

Maintenance tips for double-roller granulators include:

Inspect roller surfaces: Uneven or worn rollers can cause irregular granule size and reduced density. Regular inspection ensures uniform compression.

Check hydraulic or mechanical pressure systems: Uniform pressure is essential for granule quality. Variations can lead to weak or broken granules.

Clean rollers and feeding systems: Sticky MAP powder can accumulate, affecting granulation. Cleaning after each shift prevents blockages.

Lubricate bearings and gears: Proper lubrication reduces friction and prevents overheating.

Monitor for unusual noise and vibration: Small misalignments or bearing wear can significantly impact granule quality.

Tighten bolts and fasteners: Keeping rollers aligned and secure ensures consistent compression.

Extra tip: Double-roller granulators are highly sensitive to alignment and pressure control. Operators should keep a maintenance log, noting roller wear, hydraulic pressure levels, and any unusual sounds. This helps prevent sudden breakdowns and maintains consistent production.

Regardless of granulator type, there are some daily practices that enhance all maintenance tips for MAP Granulator:

Following these daily habits reduces downtime and ensures consistent granule quality. Operators should also record any maintenance or repairs to track machine performance over time.

At LANE, we specialize in designing and manufacturing MAP production line and complete fertilizer production lines. With over 20 years of experience, our professional engineering team helps clients optimize their production lines and provides full support, including installation, training, troubleshooting, and long-term maintenance.

Partnering with LANE makes it easier to apply maintenance tips for MAP Granulator effectively. Our ISO 9001 and CE-certified equipment ensures reliability, efficiency, and safety. We provide spare parts, technical guidance, and customized maintenance schedules, helping operators keep their MAP granulators running at peak performance.

By following proper maintenance tips for MAP Granulators, operators can prevent common issues:

Preventive care is always easier and cheaper than emergency repairs. Consistent maintenance improves granule quality, reduces downtime, and extends machine life.

MAP Granulators are essential for producing high-quality MAP fertilizer. Drum, disc, and roller granulators each require specific maintenance practices. Following these maintenance tips for MAP Granulator, including cleaning, lubrication, inspection, tightening, and monitoring, ensures consistent granules, reduces downtime, and prolongs equipment life.

With expert guidance and support from LANE, operators can maintain their MAP granulators efficiently, optimize production, and ensure long-term success in fertilizer manufacturing.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.