The fertilizer industry is undergoing a massive shift toward automation, and at the heart of this movement is the need for more efficient handling of Monoammonium Phosphate. If your facility is still relying on outdated methods, the introduction of a MAP automatic packaging system could be the single most important upgrade you make this year. For many producers, the transition to MAP automatic packaging is not just about buying a new machine; it is about redefining how their business operates in a global market that demands speed, precision, and cleanliness.

In the following sections, we will explore why MAP automatic packaging has become the industry standard, how the technology actually functions, and why partnering with an experienced manufacturer like us can make all the difference in your production efficiency.

When handling Monoammonium Phosphate (MAP), precision is the name of the game. MAP is a highly effective source of phosphorus and nitrogen, but its granular nature presents specific challenges during the bagging process. This is where MAP automatic packaging steps in to solve problems that manual labor simply cannot.

One of the biggest silent killers of profit in a fertilizer plant is “overfilling.” To avoid customer complaints about underweight bags, manual operators often overfill bags by 0.5kg or more. While this seems small, across 10,000 bags, you are essentially giving away tons of product for free. A MAP automatic packaging system uses high-precision load cells and digital controllers to ensure that every bag is accurate to within a few grams. This level of accuracy ensures that your inventory matches your sales perfectly.

Time is money. A manual bagging team can only work so fast before fatigue sets in, leading to slower speeds and more mistakes. In contrast, a MAP automatic packaging line runs at a consistent, high-speed pace from the start of the shift to the end. Whether you need to pack 200 bags or 600 bags per hour, automation allows you to meet high-demand seasons without the need for seasonal temporary labor.

Fertilizer production can be a dusty and physically demanding environment. Constant lifting of 25kg or 50kg bags leads to worker strain and long-term back injuries. Furthermore, inhaling fertilizer dust can be a health hazard. A MAP automatic packaging system is designed with integrated dust collection and enclosed filling zones. By automating the heavy lifting and containing the dust, you create a much safer and more pleasant environment for your staff.

The look of your product on the shelf matters. Bags that are manually sewn often have uneven closures or messy labels. With MAP automatic packaging, every bag is sealed perfectly, labeled clearly, and stacked neatly on pallets. This professional appearance tells your customers that you value quality, which can help you command a better price in the marketplace.

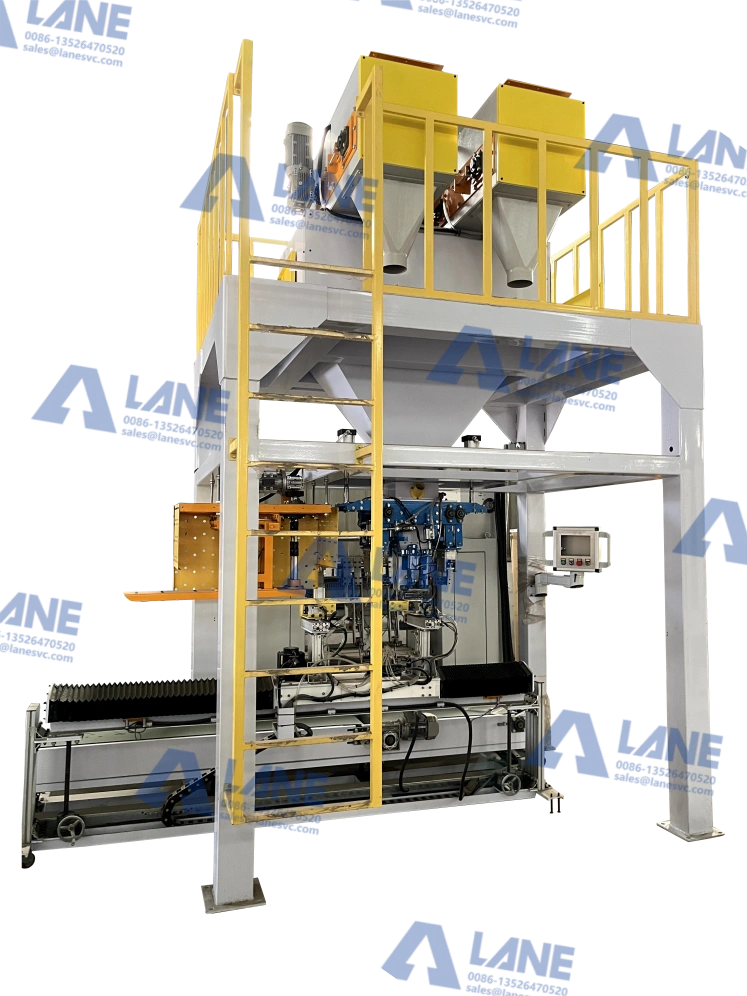

To appreciate the value of MAP automatic packaging, it helps to understand the sophisticated engineering that happens behind the scenes. While the machine looks like a single unit, it is actually a synchronized dance of several high-tech components working in harmony.

The Feeding System

The process starts at the top. MAP granules are stored in a surge hopper. Because fertilizer granules can sometimes stick together or flow inconsistently, a high-quality MAP automatic packaging machine uses vibration or gravity-fed gates to ensure a steady stream of material. This ensures that the weighing bucket is always ready for the next cycle, preventing any “hiccups” in the production line.

The Weighing and Dosing Module

This is where the magic happens. Modern MAP automatic packaging equipment uses a two-stage filling process:

Bulk Fill: The machine quickly dumps 90% of the target weight into the weighing hopper.

Dribble Feed: The machine slows down the flow to a “dribble” to hit the exact weight target. This “fast-then-slow” approach is why MAP automatic packaging can be both incredibly fast and incredibly accurate at the same time.

Automatic Bag Handling (The Pick-and-Place)

In a fully automated setup, a vacuum-powered mechanical arm reaches into a magazine of empty bags. It picks up a single bag, opens the mouth using a puff of air or mechanical fingers, and slides it onto the filling spout. This eliminates the need for a human to stand by the machine and manually feed bags, which is often the biggest bottleneck in traditional setups.

Sealing and Closing

Once the bag is filled with MAP, it is released onto a conveyor belt. The MAP automatic packaging system then guides the bag through an automatic folder and a heavy-duty sewing head (for woven bags) or a heat-sealer (for plastic bags). The result is a secure, leak-proof seal that can withstand the rigors of long-distance shipping.

The PLC Brain

The entire operation is managed by a Programmable Logic Controller (PLC). Through a user-friendly touch screen, an operator can switch between different bag sizes鈥攕uch as moving from 25kg to 50kg鈥攊n a matter of minutes. This flexibility is a core feature of high-end MAP automatic packaging solutions.

Fertilizer is naturally corrosive. If you buy a cheap machine made of low-grade steel, the chemicals in the MAP will cause rust and mechanical failure within a few years. When we design a MAP automatic packaging system, we prioritize longevity.

Stainless Steel Construction: We use high-grade stainless steel for all parts that come into contact with the fertilizer. This ensures that the MAP automatic packaging equipment remains corrosion-free and easy to clean.

Sealed Electronics: Dust and moisture are the enemies of electronics. Our control panels are sealed to NEMA or IP standards to prevent fertilizer dust from shorting out the circuits.

Heavy-Duty Motors: We use industrial-grade motors and pneumatic components that are rated for 24/7 operation, ensuring your MAP automatic packaging line doesn’t quit when you need it most.

Choosing the right equipment is only half the battle; you also need a partner who understands the fertilizer industry. Our company brings a wealth of experience to the table, ensuring your investment in MAP automatic packaging pays off for years to come.

20+ Years of Professional Experience

We have spent over 20 years focusing on the Chinese fertilizer machinery sector. We have seen the industry evolve from basic manual tools to the advanced MAP automatic packaging systems of today. This deep history means we have already solved the problems you are currently facing.

Professional Engineering and Customization

No two factories are exactly the same. You might have a low ceiling, a narrow floor plan, or unique power requirements. Our professional engineering team specializes in customized services. We don’t just ship a machine; we design and manufacture a MAP automatic packaging solution that fits perfectly into your existing production line. We can even install entire fertilizer production lines, handling everything from the initial blueprint to the final bolt.

One-Stop Service and Global Standards

We believe in building long-term relationships. Our service doesn’t end when the MAP automatic packaging machine leaves our warehouse. We provide:

On-site Installation: Our engineers can travel to your site to ensure everything is set up correctly.

Comprehensive Support: From maintenance and troubleshooting to future upgrades, we are always just a phone call away.

Quality Assurance: Our products are manufactured to ISO9001 and CE international quality standards, so you know you are getting a world-class machine.

Whether you are working with organic, compound, or liquid fertilizers, our product line is complete and professional. We are committed to helping you run an efficient, stable, and profitable operation.

If you are still on the fence about investing in MAP automatic packaging, consider the Return on Investment (ROI). Most of our clients find that the machine pays for itself within 12 to 18 months through labor savings and reduced product giveaway alone.

Beyond the immediate financial gains, there is the benefit of “peace of mind.” Knowing that your MAP automatic packaging line is running reliably means you can focus on sales, marketing, and growing your business instead of constantly fixing mechanical breakdowns or managing labor disputes.

In a world where agricultural efficiency is more important than ever, staying ahead of the curve is vital. A high-quality MAP automatic packaging system is the foundation of a modern, successful fertilizer plant.

As we have explored, the benefits of MAP automatic packaging are clear: higher accuracy, increased safety, better branding, and significantly lower long-term costs. By removing the variables of manual labor and replacing them with the consistency of automation, you set your business up for sustainable growth.

At our company, we are ready to use our 20 years of experience to help you find the perfect solution. We understand that every bag of fertilizer represents your hard work, and our MAP automatic packaging systems are designed to treat your product with the respect it deserves.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.