The MAP fertilizer manufacturing process (Monoammonium Phosphate) is a critical industrial pathway for producing one of the most widely used phosphate fertilizers in the world. MAP fertilizer is highly valued in agriculture due to its balanced ratio of nitrogen and phosphorus, high solubility, and compatibility with various soil types and crops. Understanding the MAP fertilizer manufacturing process helps producers optimize efficiency, maintain consistent quality, and minimize environmental impact.

Understanding MAP Fertilizer

Monoammonium Phosphate (MAP), with the chemical formula NHβ²³Hβ²²POβ²³, is produced by the neutralization of phosphoric acid with ammonia. The typical nutrient composition is 11% nitrogen (N) and 52% phosphorus pentoxide (Pβ²²Oβ²Ö), making it a concentrated source of both essential macronutrients.

MAP is known for:

Excellent solubility in water.

Low nitrogen volatilization loss.

Suitability for all crops and soils.

Compatibility with other fertilizers (especially in NPK blending).

Because of its stable chemical characteristics and efficiency, MAP fertilizer manufacturing process technology has been widely developed and standardized across the world.

Key Raw Materials in MAP Fertilizer Manufacturing

The two primary raw materials in the MAP fertilizer manufacturing process are:

| Material | Description | Quality Requirements |

| Phosphoric Acid (Hβ²ÉPOβ²³) | Provides phosphorus (Pβ²²Oβ²Ö) | High purity, βâΞ 52% Pβ²²Oβ²Ö |

| Ammonia (NHβ²É) | Provides nitrogen source | High purity, anhydrous ammonia |

In addition, defoaming agents, anti-caking agents, and stabilizers can be used during processing to improve product stability and reduce dusting.

Step-by-Step MAP Fertilizer Manufacturing Process

(1) Reaction and Neutralization

The MAP fertilizer manufacturing process begins with the controlled reaction of phosphoric acid and ammonia in a reactor tank.

H3βÄ΄PO4βÄ΄+NH3βÄ΄βÜ£NH4βÄ΄H2βÄ΄PO4βÄ΄

The key factors include:

Temperature control (90βÄ™120¬ΑC) to ensure complete neutralization.

Ammonia-to-acid ratio adjustment to achieve the correct pH (4.5βÄ™5.0).

Continuous mixing to prevent crystallization.

LANEβÄôs stainless steel acid-ammonia reactor ensures uniform reaction, minimal corrosion, and stable product output.

(2) Slurry Concentration and Mixing

The slurry obtained from the reaction is concentrated to the desired moisture content.

Concentration systems remove excess water and adjust viscosity before granulation. The slurry is then mixed with recycled fines and additives to achieve optimal granulation characteristics.

(3) Granulation Process

Granulation is a critical step in the MAP fertilizer manufacturing process, determining the size, shape, and hardness of the final granules.

Common granulation equipment includes:

| Granulator Type | Advantages |

| Disc Granulator (Pan Granulator) | Simple structure, adjustable granule size, suitable for MAP and NPK fertilizers. |

| Double Roller Granulator | Dry granulation, low energy consumption, no drying needed for certain formulas. |

Disc granulators are widely used for MAP because they allow precise control of granule size (2βÄ™5 mm) and uniform density.

LANEβÄôs granulation systems feature variable speed drives and automatic water spraying systems for stable particle formation and reduced dust.

(4) Drying and Cooling

After granulation, the moisture content of the MAP granules is typically 10βÄ™12%, which must be reduced to less than 2% for storage stability.

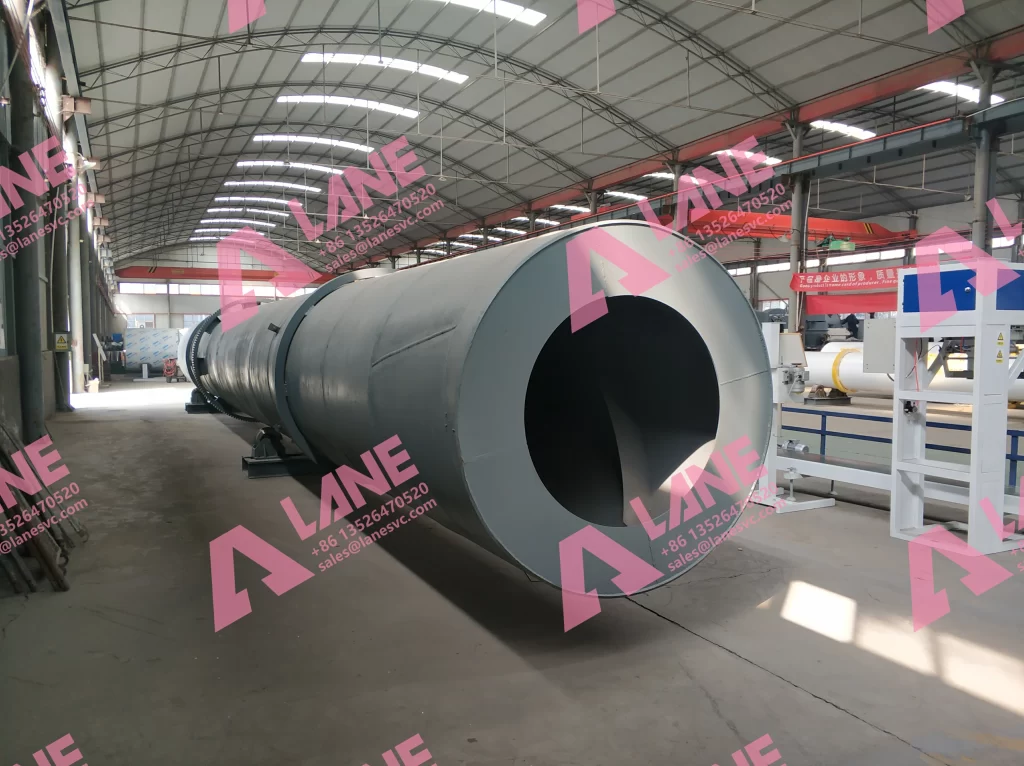

Rotary Drum Dryer: Uses hot air (from natural gas or biomass burner) to remove moisture uniformly.

Rotary Drum Cooler: Reduces the temperature of the dried granules to near ambient levels.

LANEβÄôs dryers and coolers are designed with energy-efficient air circulation systems and high thermal recovery, ensuring reduced fuel consumption and longer equipment life.

(5) Screening and Recycling

The dried MAP granules are screened using a vibrating screen. Oversized and undersized granules are recycled back to the granulation section, while qualified granules proceed to packaging.

Typical particle size distribution for MAP fertilizer:

2βÄ™4 mm: 90% qualified granules

<2 mm or >4 mm: recycled

LANEβÄôs integrated screening system features anti-blocking meshes and dust collection devices to maintain high purity and minimal product loss.

(6) Coating and Storage

To prevent moisture absorption and caking during storage, a thin coating of anti-caking agent or polishing oil is applied.

This step ensures long-term stability, easier handling, and improved appearance of MAP granules.

(7) Automatic Weighing and Packaging

The final product is conveyed to an automatic weighing and packaging system.

LANEβÄôs packaging machines are equipped with PLC control systems, weight sensors, and dust collection units, ensuring accurate, clean, and efficient bagging operations (25βÄ™50 kg bags).

| Feature | Description |

| PLC System | Real-time control of feeding and weighing |

| High Accuracy | ±0.2% weight error |

| Bagging Capacity | 5βÄ™8 bags/minute |

Common FAQs about MAP Fertilizer Manufacturing Process

Q1: What is the difference between MAP and DAP fertilizers?

A1: MAP (Monoammonium Phosphate) has an N:P ratio of 11:52, while DAP (Diammonium Phosphate) is 18:46. MAP is slightly more acidic, making it suitable for alkaline soils, whereas DAP has higher nitrogen content.

Q2: What granulation equipment is most suitable for MAP production?

A2: Disc granulators are ideal due to their control over granule size and uniform density. Double roller granulators are also an option for low-moisture, energy-efficient operations.

Q3: Can MAP be used in water-soluble formulations?

A3: Yes, MAP has excellent solubility, making it suitable for drip irrigation and foliar applications when properly processed.

Q4: What is the typical production capacity of a MAP line?

A4: LANE supplies MAP lines ranging from 5,000 to 200,000 tons per year, depending on customer requirements and raw material supply.

The production process of monoammonium phosphate (MAP) fertilizer is a sophisticated combination of chemistry, engineering and automation technology, which can transform raw materials into highly efficient phosphate fertilizers. From neutralization to granulation and packaging, each step requires precise control and reliable equipment.

With its advanced technology, sophisticated processes and commitment to sustainable fertilizer production, LANE provides optimized MAP fertilizer production lines for global customers, ensuring stable product performance, low operating costs and long-term reliability.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.