Early crop development is a fragile stage. For cereals such as wheat, corn, and barley, the first few weeks decide root strength, plant uniformity, and final yield potential. This is why MAP for early crop growth is often discussed as a practical solution for early nutrition problems. Still, many challenges begin long before the fertilizer reaches the field.

Cold soil, unstable moisture, and slow nutrient movement all limit early root activity. Even when nutrients are present in the soil, young plants may not absorb them efficiently. Farmers rely on MAP for early crop growth to deliver fast-acting phosphorus and nitrogen, but the real success of these products depends heavily on how they are manufactured.

One common issue in early cereal growth is uneven emergence. Plants sprout at different speeds, creating mixed growth stages in the same field. This often comes from uneven fertilizer spreading or unstable nutrient content. When granules break during transport or contain inconsistent composition, crops receive uneven feeding.

Another major problem is weak root development. Without timely phosphorus supply, roots remain shallow and thin. This reduces water uptake and makes crops more sensitive to stress. For this reason, MAP for early crop growth must dissolve evenly and reach roots quickly after application.

Weather adds pressure. Rain can wash away fine particles, while dry conditions can delay nutrient release. If fertilizer granules are too soft or contain excess moisture, early losses become unavoidable. These risks highlight one key fact: fertilizer quality is closely tied to production equipment.

Producing stable fertilizer is not just about formula design. It is about controlling reaction, shaping granules, removing moisture, and managing dust. For MAP for early crop growth, each production step must support early-stage performance in the field.

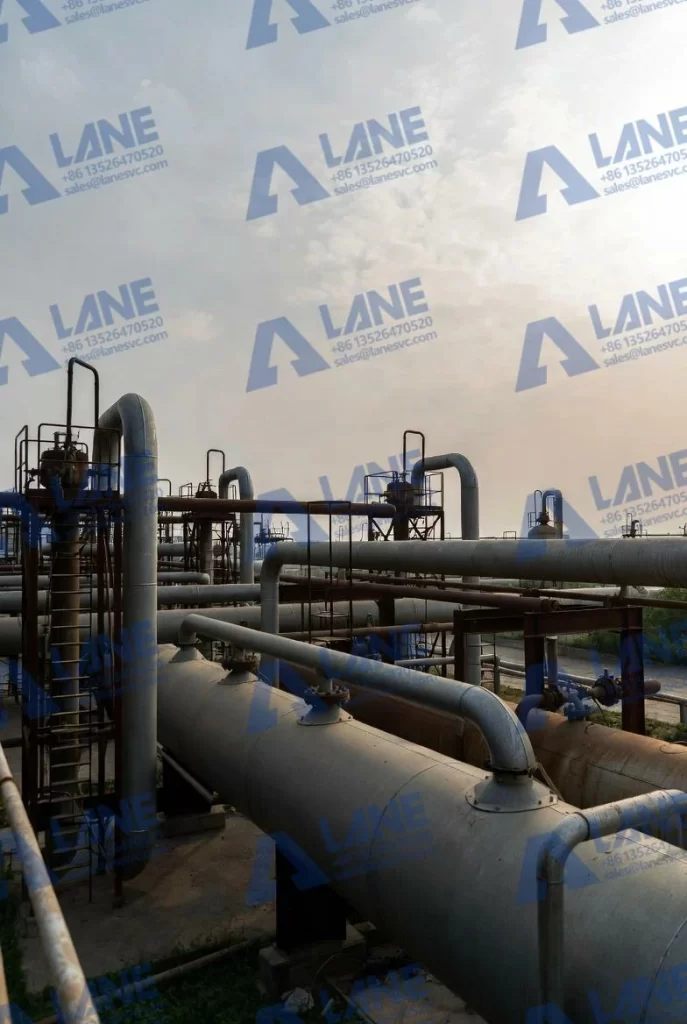

Modern fertilizer plants rely on several core machines working together. If one step fails, granule quality, nutrient balance, or environmental safety can all suffer. That is why equipment selection and process design deserve special attention.

Tube reactor: where the reaction begins

The chemical reaction stage is the foundation of the entire process. In MAP fertilizer production, a tube reactor is used to complete the core reaction. Built with high-temperature and corrosion-resistant alloy materials, this reactor can handle harsh chemical conditions while remaining stable over long periods.

Inside the reactor, raw materials react fully and release heat. This reaction heat is not wasted. It is used directly to remove water from the slurry, improving energy efficiency and reducing later drying pressure. A stable reaction ensures consistent nutrient composition, which is critical for MAP for early crop growth performance.

Rotary drum granulator: shaping the fertilizer

Once the reaction slurry is ready, it must be transformed into solid particles. This is done using a rotary drum granulator. The drum is installed with a slight incline, allowing material to roll naturally as the drum rotates.

During this process, liquid material gradually forms round granules. The goal is to produce particles within a narrow size range, usually suitable for even field application. For MAP for early crop growth, uniform granules help ensure equal nutrient delivery and smooth spreading, especially during early-season application.

Rotary drum dryer: strengthening the granules

Fresh granules still contain moisture and lack strength. Drying is essential. A rotary drum dryer is used to remove excess water and improve hardness. Hot air enters the system at controlled temperatures, high enough to evaporate moisture but gentle enough to protect nutrient structure.

Proper drying improves storage stability and reduces breakage during transport. Strong granules mean less dust, less loss, and better results in the field. This step directly supports the reliability of MAP for early crop growth products.

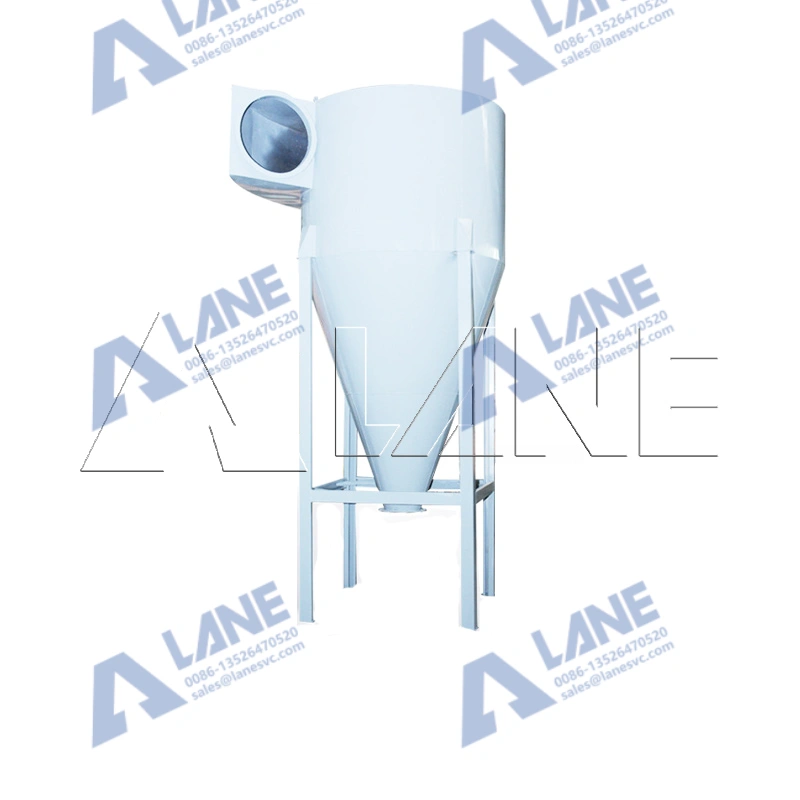

Dust collection: protecting efficiency and the environment

Dust is often overlooked, but it creates both product loss and environmental risk. During drying and screening, fine particles can escape. To control this, plants use bag filters or cyclone dust collectors.

With very high collection efficiency, these systems capture escaped powder and return it to production. This not only improves material utilization but also protects the working environment and surrounding area. Clean production is increasingly important for fertilizer plants producing MAP for early crop growth at scale.

Each machine plays a role, but real stability comes from system integration. A balanced production line ensures smooth material flow, controlled moisture, and consistent granule size. When capacities are mismatched, quality drops and energy use rises.

Producers focusing on MAP for early crop growth also need flexibility. Raw materials may vary, and output targets may change. Equipment must be durable, adjustable, and easy to maintain over time.

At LANE, we have spent over 20 years working in fertilizer machinery manufacturing. We understand that early crop growth problems are often linked to production instability. That is why we focus on equipment reliability, customization, and full-line solutions for MAP for early crop growth.

Our company designs and manufactures complete MAP fertilizer production lines, from reaction systems to granulation, drying, and dust control. Our engineering team works closely with customers to match equipment to real production needs. All our systems meet ISO9001 and CE standards.

We also provide installation, commissioning, and long-term after-sales support. From maintenance guidance to line upgrades, we stay involved to ensure stable operation. By supporting consistent production, we help our customers deliver dependable MAP for early crop growth fertilizers to the market.

Early cereal growth leaves little room for mistakes. Weak roots, uneven emergence, and nutrient loss can limit yield before the season truly begins. By addressing these challenges with proper machinery and system design, fertilizer producers can strengthen the performance of MAP for early crop growth. Behind every strong field start, there is a well-designed production line working quietly in the background.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.