In modern fertilizer plants, moisture content control in phosphate fertilizer is no longer something handled only by operators’ experience. It is strongly connected to the type of machines used on the production line. From crushing to granulation and drying, every piece of equipment plays a clear role in managing water inside the fertilizer.

Understanding how these machines affect moisture helps producers avoid common problems such as caking, weak granules, and poor storage performance.

The first step of moisture content control in phosphate fertilizer starts with crushers and storage equipment. Chain crushers and hammer crushers reduce phosphate rock and other raw materials into suitable sizes. If materials stay too long in open storage bins, they can easily absorb moisture from the air. Properly designed storage systems with covers and smooth discharge reduce unnecessary moisture intake before processing.

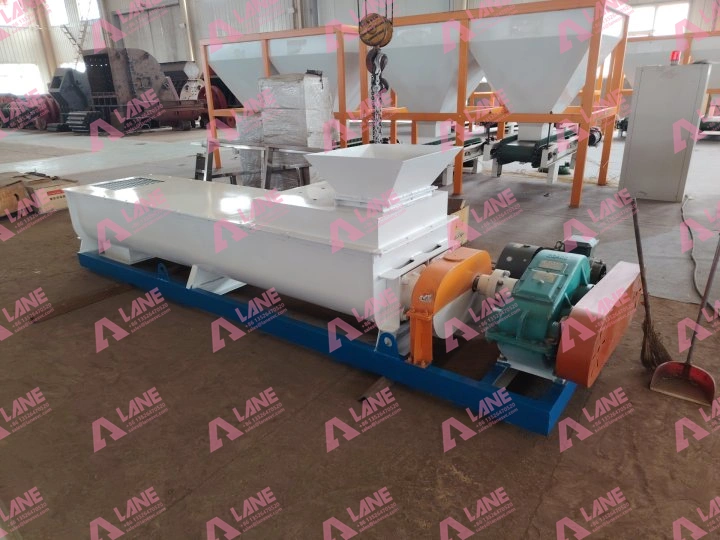

Belt feeders and automatic batching systems help stabilize moisture content control in phosphate fertilizer by keeping material flow even. When feeding is unstable, materials may pile up, causing local moisture concentration. Accurate batching reduces this risk and creates a steady foundation for mixing and granulation.

Mixers directly affect moisture content control in phosphate fertilizer. Horizontal mixers and double-shaft mixers combine solid materials with water or liquid additives. Good mixing equipment spreads moisture evenly, avoiding wet lumps or dry powder. This makes later granulation easier and more predictable.

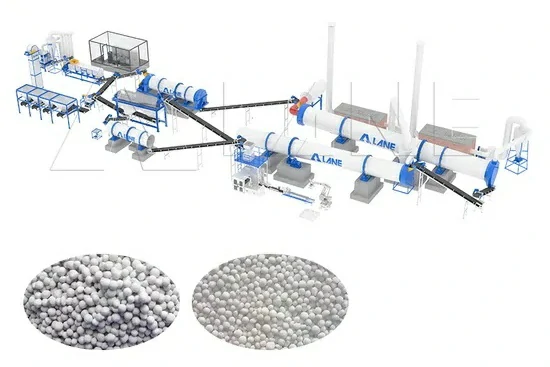

Rotary drum granulators are one of the most common machines for moisture content control in phosphate fertilizer. Inside the rotating drum, materials roll and grow into granules while water is carefully added. Drum speed, inclination, and spray volume all influence how much moisture remains inside the granules. With proper adjustment, rotary drum granulators produce strong particles with balanced moisture.

Drying is a core step in moisture content control in phosphate fertilizer. Rotary drum dryers remove excess water after granulation. By adjusting temperature, airflow, and drying time, moisture can be reduced gradually without damaging the fertilizer. A stable dryer ensures that each batch reaches a safe moisture level for storage and transport.

After drying, rotary drum coolers continue supporting moisture content control in phosphate fertilizer. Hot fertilizer easily absorbs moisture from surrounding air. Cooling machines reduce product temperature, lowering the risk of condensation and helping granules stay dry and strong.

Vibrating screens and rotary screening machines help maintain moisture content control in phosphate fertilizer by removing oversized, undersized, or broken particles. These particles often have uneven moisture and are recycled back into the system. This keeps the final product consistent.

Coating machines improve moisture content control in phosphate fertilizer during storage. A thin coating layer reduces moisture absorption from air and prevents caking. This is especially important for phosphate fertilizer transported over long distances or stored for extended periods.

Packaging machines are the final step in moisture content control in phosphate fertilizer. Automatic packing machines reduce exposure to humid air and human handling. Proper warehouse design and moisture-proof bags help preserve the moisture balance achieved during production.

At LANE, moisture content control in phosphate fertilizer has been a focus for more than 20 years. We design and manufacture complete fertilizer production lines, including crushers, mixers, rotary drum granulators, dryers, coolers, screening machines, coating machines, and packing systems.

We have a professional engineering team that customizes equipment and full production lines based on raw materials, capacity needs, and local climate conditions. From equipment manufacturing and on-site installation to after-sales service and upgrades, we provide one-stop support. All our products meet ISO9001 and CE standards, ensuring reliable quality and long-term stable operation.

In real production, moisture content control in phosphate fertilizer is the result of smart equipment selection and good system design. By choosing the right machines—especially rotary drum granulators or double roller press granulators—producers can achieve stable moisture levels, strong granules, and reliable product quality. With experienced partners and customized solutions, moisture control becomes a natural part of daily production, not a constant challenge.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.