Hey everyone! Ever wondered what it takes to make the fertilizers that help our food grow? It’s more than just mixing chemicals; itβÄôs also about being super responsible with our environment. Today, we’re diving into something super important: the pollution control equipment for DAP plant operations. Think of it as the unsung hero behind cleaner air and water in the world of fertilizer manufacturing. It’s truly fascinating how much science goes into making sure these plants operate without harming our planet.

DAP plants are fantastic for producing a concentrated fertilizer that boosts crop yields worldwide. But let’s be real, the process itself isn’t exactly a breath of fresh air without proper management. When phosphate rock reacts to create DAP, it releases a cocktail of potential pollutants:

Fluoride gases: These come from the phosphate rock itself and can be harmful if released into the atmosphere unchecked.

Ammonia (NHβ²É): A key ingredient in DAP, ammonia gas can escape during various reaction and drying stages. While essential for fertilizer, too much in the air isn’t good.

Particulate matter (PM): Basically, tiny dust particles from the fertilizer product itself. Think of it like fine powder escaping into the air.

Without robust pollution control equipment for DAP plant facilities, these emissions could easily exceed environmental standards, affecting local ecosystems and communities. So, what kind of cool tech do these plants use to keep things clean? Let’s take a look!

Imagine a superhero team, but instead of capes, they have scrubbers and filters! That’s essentially what a DAP plant’s pollution control system is like.

This is arguably the MVP of pollution control equipment for DAP plant operations. It’s all about capturing gases and tiny particles before they even think about leaving the chimney.

Venturi Scrubbers: The High-Speed Dust & Gas Trappers

Picture a narrow throat where gas speeds up like crazy. As it zips through, liquid (often recycled phosphoric acid) is sprayed in, creating a chaotic mix. The high-speed impact forces tiny dust particles and gas molecules (like ammonia and fluorides) to get “wet” and fall out of the gas stream. It’s like throwing water at a fast-moving cloud to make it rain, but way more efficient!

The cool thing is, the recovered phosphoric acid, now loaded with ammonia and fluorides, can often be sent right back into the production process. Talk about recycling!

Spray Towers & Packed Towers: The Deep Cleaners

After the Venturi scrubber handles the heavy lifting, the gas might move into a spray tower or a packed tower. Here, more liquid (usually water or a mild chemical solution) is sprayed downwards while the gas moves upwards through layers of packing material. This provides a huge surface area for any lingering fluorides or ammonia to be absorbed. ItβÄôs like a super thorough shower for the gas, ensuring itβÄôs squeaky clean before release.

Even after the scrubbing, there’s still the challenge of fertilizer dust. This is where dedicated dust removal pollution control equipment for DAP plant facilities shines.

Cyclone Dust Removal: The Whirlwind Wizards

Think of a cyclone as a mini-tornado. Dusty air enters, spins around, and the centrifugal force pushes the heavier fertilizer particles to the walls, where they slide down and are collected. The cleaner air then exits from the top. Cyclones are great for capturing larger particles and are often the first line of defense.

Pulse Dust Removal: The Ultimate Dust Bunnies

For the really fine dust that cyclones miss, baghouses step in. Imagine a giant vacuum cleaner with hundreds of fabric bags. Dusty air passes through these bags, trapping even the tiniest particles. When the bags get full, they’re shaken or pulsed with air to release the collected dust, which can then be reused or safely disposed of. This is a crucial piece of pollution control equipment for DAP plant lines, especially in the final drying and packaging stages.

Pollution control isn’t just about air; it’s about water too! DAP plants produce some wastewater, especially from the scrubbing systems.

Wastewater Treatment & Recycling: Modern plants aim for a “closed-loop” system, meaning they treat and reuse as much water as possible. This involves clarification (removing solids), pH adjustment, and sometimes even advanced filtration. The goal is to minimize fresh water intake and eliminate wastewater discharge.

Phosphogypsum Management: The production of phosphoric acid (a precursor to DAP) generates phosphogypsum, a byproduct. While not directly from DAP production, managing its disposal safely, often with lined impoundments to prevent groundwater contamination, is an integral part of overall pollution control equipment for DAP plant complexes.

Even the best pollution control equipment for DAP plant operations needs to be monitored.

Continuous Emission Monitoring Systems (CEMS): These are like the plant’s eyes and ears on the exhaust stacks. CEMS continuously measure the concentration of pollutants like fluorides, ammonia, and particulate matter in the gases being emitted. This data is often sent directly to environmental authorities, ensuring real-time compliance and transparency. ItβÄôs how we know the pollution control equipment for DAP plant is working perfectly.

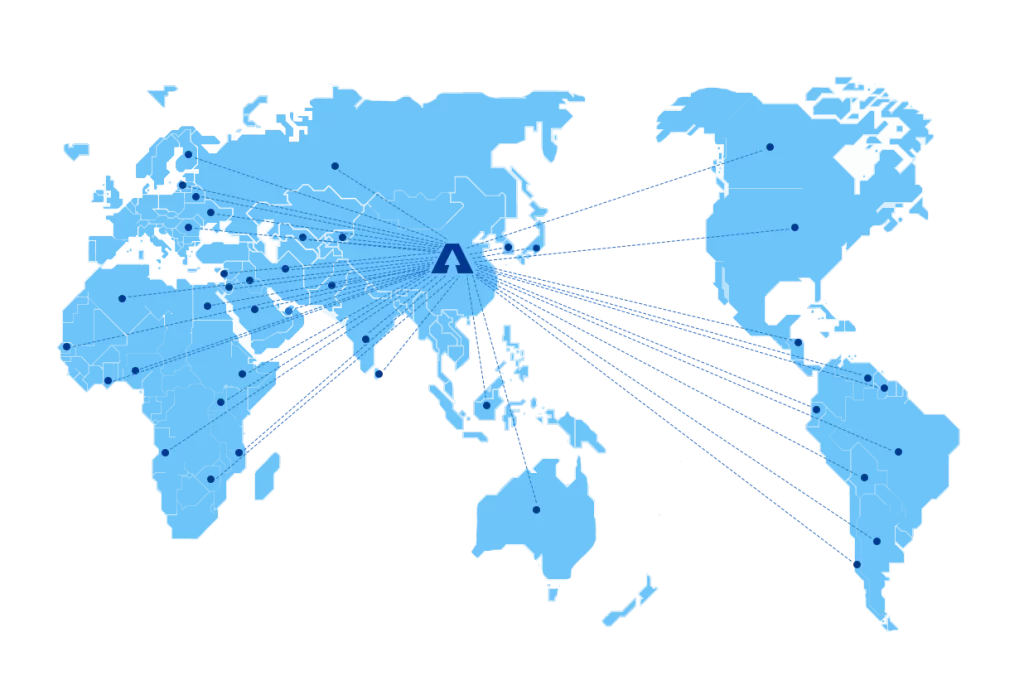

At LANE, we’ve been specializing in fertilizer machinery in China for more than 20 years, and we’ve poured all that experience into understanding not just how to make fertilizer, but how to do it responsibly. Our professional engineering team can design, manufacture, and even install entire fertilizer production lines tailored to your specific needs, always with an eye on top-tier pollution control equipment for DAP plant integration.

We pride ourselves on providing full-scale servicesβÄîfrom the initial installation to comprehensive after-sales support. Whether it’s routine maintenance, troubleshooting an unexpected hiccup, or planning upgrades for your existing pollution control equipment for DAP plant, we are always here to ensure your production line operates at its best. Our quality standards meet both ISO9001 and CE international certifications. We are experts at providing complete fertilizer production lines, NPK production lines, organic fertilizer machines, and compound fertilizer machines, all designed with effective environmental safeguards in mind. When you choose LANE, you’re not just getting equipment; you’re getting a partner committed to efficient and environmentally sound production, including the best pollution control equipment for DAP plant facilities.

The advancements in pollution control equipment for DAP plant facilities are truly remarkable. They allow us to meet the growing global demand for food through efficient fertilizer production, all while safeguarding our precious environment. ItβÄôs a testament to human ingenuity and our commitment to a sustainable future. Every piece of pollution control equipment for DAP plant contributes to a cleaner, greener world!

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.