When customers plan a fertilizer production project, one common question appears early in the discussion: what are the benefits of ammonium phosphate over urea in real manufacturing and agricultural use? We recently completed a compound fertilizer production line for a Southeast Asian client, and this question came up many times during design, testing, and installation.

Our company has worked in fertilizer equipment manufacturing for more than 20 years. We design, build, install, and support full fertilizer production lines. In this project, understanding the value of ammonium phosphate over urea helped the customer make a confident investment decision.

In fertilizer production, raw material stability matters. Urea is widely used because it is simple to produce and easy to transport. However, many producers now prefer ammonium phosphate over urea when making compound fertilizers because of better nutrient balance and easier blending performance.

During the early planning stage of this project, our engineering team helped the client test different formulas. We showed how choosing ammonium phosphate over urea improved granulation stability and reduced moisture problems during drying.

Because we provide customized fertilizer machinery, we were able to design feeding systems that handled phosphate materials smoothly. This flexibility is one reason customers choose us when deciding between ammonium phosphate over urea in production design.

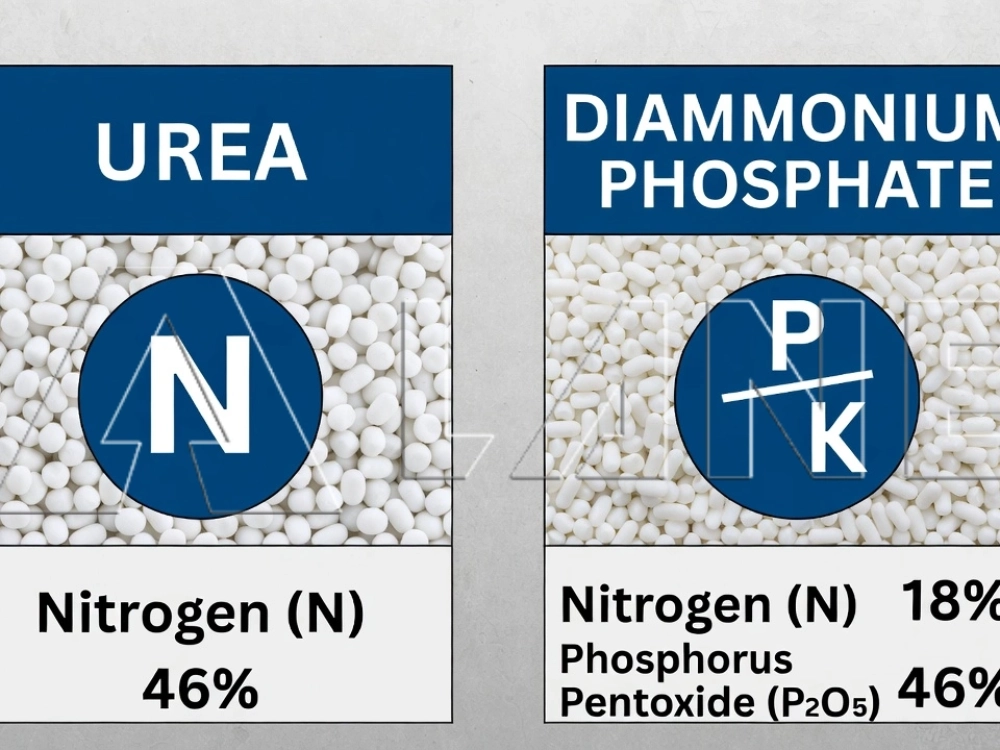

Farmers often need both nitrogen and phosphorus in one fertilizer. That is another reason producers consider ammonium phosphate over urea when building compound fertilizer lines.

Ammonium phosphate provides two important nutrients in a single material. Urea mainly provides nitrogen. This difference may seem simple, but in real fertilizer production it changes mixing ratios, storage requirements, and final product quality.

In this project, the customer wanted to produce NPK fertilizer for vegetable farms. After testing, they clearly saw the advantage of ammonium phosphate over urea in achieving balanced nutrient content without adding extra materials.

Our engineers adjusted the granulator design and drying temperature to match the chemical behavior of phosphate materials. With more than two decades of industry experience, we know how to optimize equipment when customers select ammonium phosphate over urea.

Another practical advantage of ammonium phosphate over urea is storage stability. Urea absorbs moisture easily in humid environments, which can cause caking during storage and transport.

In tropical regions, this becomes a serious issue. The client in this case had previously experienced warehouse blockages caused by urea-based fertilizer. That experience pushed them to explore ammonium phosphate over urea for their new production line.

We redesigned the raw material storage system to include controlled feeding and sealed conveyors. Our team installed the complete line and trained operators to manage phosphate materials safely. When customers switch to ammonium phosphate over urea, proper material handling design becomes very important.

Because we provide full installation and after-sales service, the client felt confident operating the new system from the first day.

Granulation is one of the most important steps in fertilizer manufacturing. Material behavior directly affects particle strength and appearance.

In our testing phase, we demonstrated how choosing ammonium phosphate over urea improved particle hardness and reduced dust generation. The rotary drum granulator produced more uniform fertilizer granules.

Our company specializes in compound fertilizer equipment, and we often recommend process adjustments when customers select ammonium phosphate over urea. Small changes in binder ratio, drum speed, and drying temperature can greatly improve results.

Because our equipment is designed by our own engineering team, we can customize every section of the production line. This flexibility helps customers fully benefit from ammonium phosphate over urea in large-scale production.

The customer in this project wanted a production line that could run continuously with minimal downtime. After comparing formulas, they found another advantage of ammonium phosphate over urea: fewer blockages in the mixing and granulation systems.

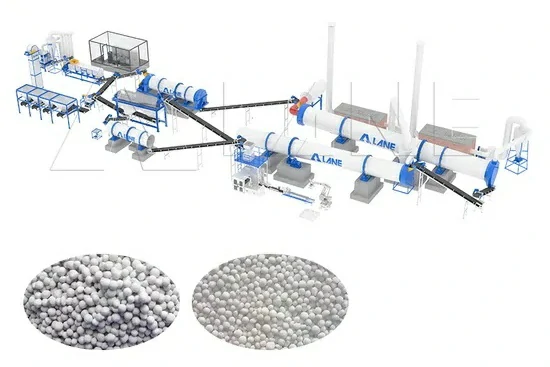

We installed the entire fertilizer production line, including batching equipment, crusher, mixer, granulator, dryer, cooler, screening machine, and packing system. Each part was tested using ammonium phosphate materials.

With ISO9001 and CE-certified manufacturing standards, our machines operate reliably even under heavy workloads. When customers adopt ammonium phosphate over urea, stable equipment design ensures consistent fertilizer quality.

Our after-sales team also provides maintenance support, troubleshooting, and future upgrade services. This long-term support is essential when switching production materials.

Some producers first believe urea is always cheaper. But real production costs include more than raw material price. In many cases, the operational benefits of ammonium phosphate over urea reduce long-term expenses.

For example, improved granule strength reduces recycling material. Better storage stability lowers product loss. These small improvements add up over time.

During this project, we helped the client calculate operating costs. They discovered that using ammonium phosphate over urea actually improved profitability after several months of production.

Because we offer complete fertilizer production solutions — including organic fertilizer, compound fertilizer, and liquid fertilizer equipment — we can help customers compare different material strategies in real production environments.

When the equipment arrived at the customer’s factory, our installation engineers stayed on site to assemble and test the machines. This is part of our one-stop service approach.

During commissioning, we again verified the benefits of ammonium phosphate over urea by running continuous production tests. The granules showed consistent size, good strength, and low moisture content.

Our company believes that equipment performance must be proven in real production conditions. That is why we support customers from design to installation and operation when choosing ammonium phosphate over urea.

The client’s operators quickly learned how to manage the system. After one week of training, the production line was running smoothly.

Modern agriculture increasingly focuses on efficient fertilizer use. This is another reason producers consider ammonium phosphate over urea in compound fertilizer manufacturing.

Because ammonium phosphate contains phosphorus, it supports root development in crops. Farmers using the fertilizer produced by this new line reported strong early plant growth.

From a manufacturing perspective, ammonium phosphate over urea also simplifies formula design for multi-nutrient fertilizers.

Our engineering team often works with fertilizer producers to adjust equipment for different agricultural needs. With more than 20 years of experience in China’s fertilizer machinery industry, we understand how material selection affects production efficiency and field performance.

After three months of operation, the customer shared production data with us. The line remained stable, and fertilizer quality met market requirements. Their decision to use ammonium phosphate over urea proved successful.

We continue to provide technical support and maintenance guidance. Our goal is not only to sell machines but to help customers operate successful fertilizer factories.

Because we design and manufacture equipment for organic fertilizer, compound fertilizer, and liquid fertilizer production, we can support future expansion projects. Many returning customers consult us again when considering ammonium phosphate over urea for new fertilizer products.

From production efficiency to nutrient balance, there are many reasons fertilizer manufacturers choose ammonium phosphate over urea. In real factory conditions, the difference becomes clear through better granulation performance, storage stability, and balanced fertilizer formulas.

In this completed production line project, the customer saw clear operational benefits from selecting ammonium phosphate over urea. With our customized equipment design, professional engineering support, installation service, and reliable after-sales assistance, the production line continues to operate smoothly.

For fertilizer producers planning new equipment or upgrading existing lines, understanding the practical advantages of ammonium phosphate over urea can help guide smarter investment decisions.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.