In today’s fertilizer industry, producers are under pressure to deliver stable quality, control costs, and meet environmental expectations. That is why the comparison of DAP granulation methods has become a popular topic across global fertilizer markets. Choosing the right granulation process is not just a technical decision—it directly affects production efficiency, product appearance, and long-term operating costs.

Diammonium phosphate (DAP) is widely used in agriculture, and its granulation process plays a key role in how the final product performs in the field. In this article, we break things down in a simple, news-style way, so even readers without an engineering background can follow along.

When people talk about fertilizer quality, they often think about nutrient content. But granule size, hardness, and uniformity matter just as much. A smart comparison of DAP granulation methods helps manufacturers understand how different systems influence these factors.

Granulation also affects storage, transportation, and customer satisfaction. Poor granules can lead to dust, caking, or uneven application in the field. That’s why more producers are taking a closer look at how their DAP granules are made.

There are several ways to produce DAP granules, and each has its own strengths. A balanced comparison of DAP granulation methods usually focuses on the most widely used options in the industry today.

The two most common approaches are drum granulation and pan granulation. While both aim to create uniform granules, they differ in operation style, space requirements, and process control.

Rotary drum granulation is the most common choice for large-scale DAP production. In any serious comparison of DAP granulation methods, this process usually represents the industrial standard.

Liquid slurry is sprayed into a rotating drum, where it gradually forms round and solid granules. The final product has high strength and good size consistency, making it ideal for transport and bulk use.

This method is widely used for mass agricultural-grade DAP, especially in plants that focus on stable, high-volume output and cost control.

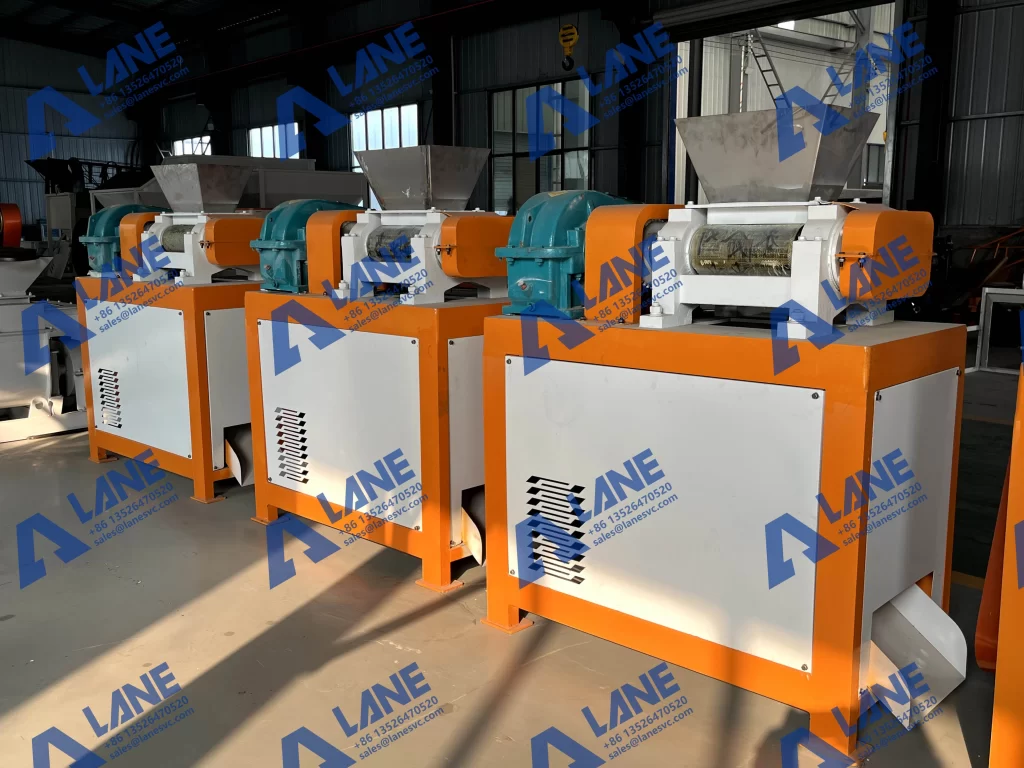

Double roller granulation is quite different from traditional wet granulation. In a practical comparison of DAP granulation methods, it stands out for its energy-saving advantages.

Raw materials are pressed directly into shape by rollers, forming granules or flat particles without the need for drying. This reduces energy consumption and simplifies the process flow.

Because of its flexibility and compact layout, this method is often chosen by small to medium-sized plants producing compound fertilizers or bulk blending (BB) fertilizers.

Disc granulation is known for its simplicity. In many comparison of DAP granulation methods discussions, it is described as the easiest system to operate.

Materials are rolled into spherical granules inside a rotating disc. Operators can visually control the process and make quick adjustments. Investment cost is very low, which makes it suitable for small-scale fertilizer processing or basic production lines.

However, its production capacity is limited compared to drum systems.

Spray drying granulation is a more specialized solution. In a detailed comparison of DAP granulation methods, this approach is usually linked to high-end or industrial applications.

Liquid material is atomized into hot air, forming very fine and dry spherical particles. The final product has excellent solubility and extremely low moisture content.

This method is commonly used for water-soluble fertilizers or industrial-grade raw materials rather than standard agricultural DAP.

Modern fertilizer plants must also think about emissions, dust control, and energy use. A well-rounded comparison of DAP granulation methods includes these environmental and operational factors.

Some systems are easier to seal and connect with dust collection equipment. Others may consume more energy or require more frequent maintenance. These details can strongly influence long-term operating comfort and compliance with local regulations.

From an investment point of view, the comparison of DAP granulation methods often comes down to upfront cost versus long-term value. Drum granulation lines usually require higher initial investment but offer lower unit costs at scale.

Pan granulation systems, on the other hand, tend to be more affordable at the beginning and quicker to install. For new producers or expanding companies, this flexibility can be attractive.

Below is a simple table often used in a comparison of DAP granulation methods to help readers see the differences at a glance:

| Item | Drum Granulation | Disc Granulation |

| Production Capacity | High | Medium |

| Operation Style | Continuous | Flexible |

| Space Requirement | Larger | Smaller |

| Adjustment Speed | Moderate | Fast |

| Typical Users | Large plants | Small to mid-size plants |

As global agriculture evolves, fertilizer producers are upgrading their plants. Industry news shows that the comparison of DAP granulation methods is no longer just about equipment—it’s about matching technology with market needs.

Automation, stable output, and easier maintenance are becoming top priorities. Producers are also looking for partners who can support them beyond equipment delivery.

At LANE, we’ve spent over 20 years working in fertilizer machinery manufacturing, and we understand the real-world meaning behind every comparison of DAP granulation methods. Our experience in China’s fertilizer equipment industry has given us deep insight into what actually works on site.

We have a professional engineering team that designs and customizes equipment based on customer needs. From single machines to complete DAP production lines, we handle design, manufacturing, installation, and commissioning. We also provide full after-sales support, including maintenance, troubleshooting, and upgrades.

Our equipment meets international quality standards such as ISO9001 and CE, giving customers confidence in long-term operation. Whether it’s organic fertilizer, compound fertilizer, or liquid fertilizer equipment, we focus on reliable performance and practical solutions.

In the end, a clear comparison of DAP granulation methods helps producers make smarter decisions that fit their scale, budget, and future plans. There is no single “best” method—only the best match for your production goals.

By understanding the strengths of each granulation approach and working with an experienced partner, fertilizer producers can build stable, efficient, and future-ready DAP production lines.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.