For many fertilizer buyers and investors, the first question is always simple: can we get stable supply at a reasonable cost? In many African countries, imported fertilizers are expensive and sometimes arrive late. Because of this, DAP fertilizer manufacturing in Africa is becoming a topic that more people are paying attention to. Local production is no longer just an idea for the future. It is slowly turning into a real solution for today鈥檚 farming needs.

DAP fertilizer is well known for helping crops grow strong roots and better yields. Farmers like it because it is easy to use and works for many kinds of soil. With food demand growing every year, DAP fertilizer manufacturing in Africa is now closely linked to food security and economic growth.

From a customer鈥檚 point of view, fertilizer is not just a product. It is a tool that decides whether crops grow well or not. When fertilizers are imported, prices can change quickly because of shipping costs, exchange rates, or global supply problems. This is why DAP fertilizer manufacturing in Africa is becoming more attractive to governments and private companies.

Local production means shorter delivery time and better price control. It also allows producers to adjust fertilizer quality based on local soil needs. For farmers, this often means more reliable supply before planting season. For investors, DAP fertilizer manufacturing in Africa offers a chance to build long-term business with stable demand.

Even though DAP fertilizer sounds technical, the production process itself is quite clear. In DAP fertilizer manufacturing in Africa, phosphate rock is first processed into phosphoric acid. This acid is then mixed with ammonia to create DAP slurry. After that, the slurry goes through granulation, drying, cooling, screening, and packing.

Each step needs the right machine to work smoothly. If one part fails, the whole line may stop. That is why equipment choice is very important in DAP fertilizer manufacturing in Africa. Simple design, stable operation, and easy maintenance are often more important than very advanced technology.

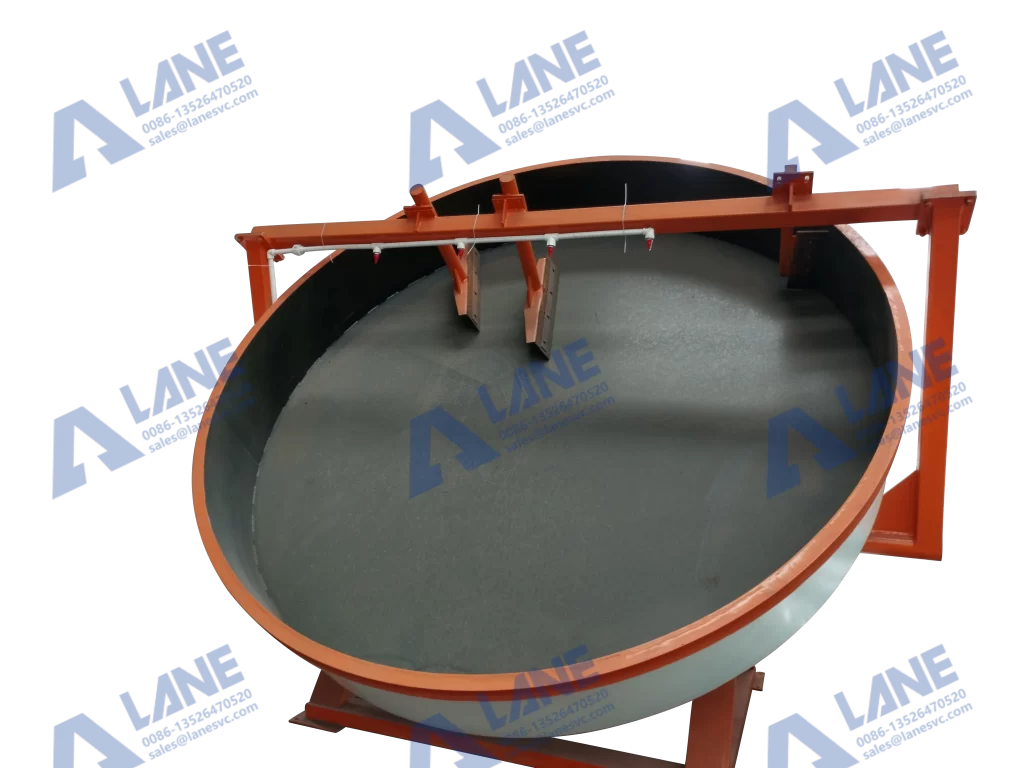

A complete DAP production line includes several key machines. Crushers and ball mills are used at the beginning to prepare phosphate rock. Reactors and neutralizers handle the chemical reaction. Granulators shape the fertilizer into small round particles that are easy to store and transport.

In DAP fertilizer manufacturing in Africa, rotary drum granulators and disc granulators are both commonly used. After granulation, dryers remove extra water, and coolers lower the temperature of the product. Screening machines separate good particles from small or broken ones, which can be sent back into the process.

Dust collectors and gas scrubbers are also important. They help keep the air clean and protect workers. These systems are now a standard part of DAP fertilizer manufacturing in Africa, especially as environmental rules become stricter.

While the opportunity is big, DAP fertilizer manufacturing in Africa also faces real challenges. In some areas, power supply is not always stable. In others, skilled workers are hard to find. Transporting raw materials and finished products can also be difficult because of road and port conditions.

Because of these issues, fertilizer plants need equipment that is strong and easy to operate. Complicated machines may look good on paper, but they can cause problems in real production. Many successful DAP fertilizer manufacturing in Africa projects focus on reliability first, not complexity.

Good design can solve many problems before they happen. In DAP fertilizer manufacturing in Africa, production lines are often designed in a modular way. This means each section can work independently and is easier to repair or upgrade later.

Clear layout, simple control systems, and easy access for maintenance all help reduce downtime. When operators understand how the machines work, they feel more confident. Over time, this improves production efficiency and product quality in DAP fertilizer manufacturing in Africa.

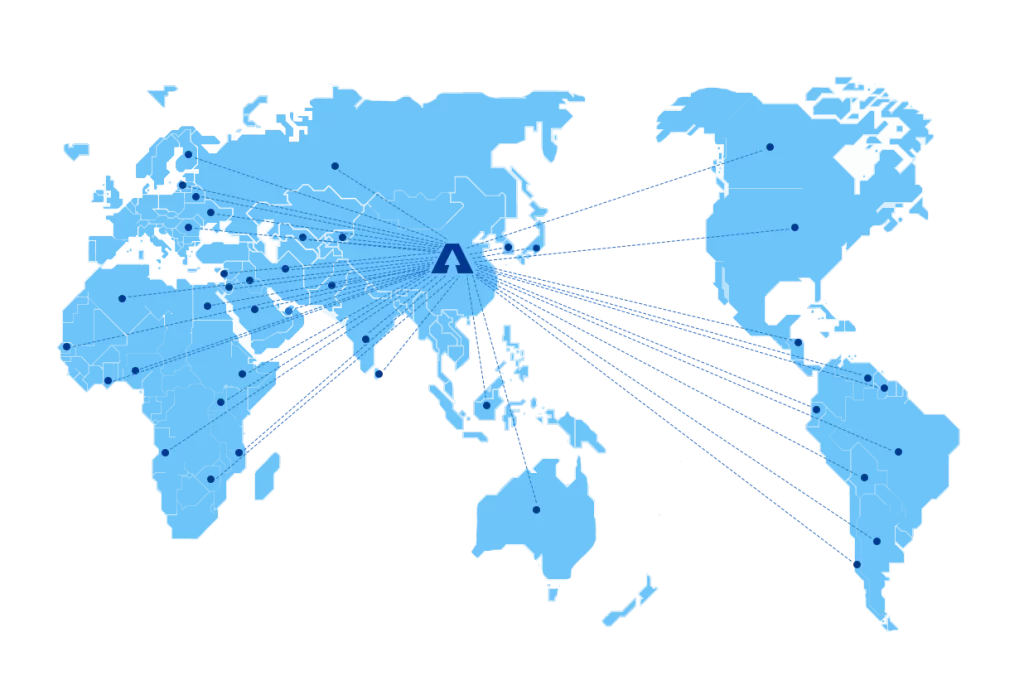

As equipment suppliers, we understand that customers do not just buy machines. They are building a long-term business. At LANE, our company has focused on fertilizer machinery manufacturing for more than 20 years. We work closely with clients involved in DAP fertilizer manufacturing in Africa to design production lines that fit real local conditions.

We handle equipment design, manufacturing, and installation, and we stay involved after the line starts running. Our engineering team provides technical guidance, maintenance support, and solutions when problems appear. We follow ISO 9001 and CE quality standards, so customers can trust the safety and performance of our equipment. Our goal is simple: help our clients keep their production lines running smoothly.

Today, environmental protection is no longer optional. In DAP fertilizer manufacturing in Africa, plants must control dust, waste gas, and wastewater. Modern fertilizer lines include dust collectors, scrubbers, and water treatment systems as standard equipment.

Safety is just as important. Ammonia handling, high temperatures, and moving machines all require careful management. Clear safety rules, proper training, and reliable equipment help reduce risks. These measures also make DAP fertilizer manufacturing in Africa more acceptable to local communities and authorities.

The future of DAP fertilizer manufacturing in Africa looks positive. More countries are investing in local fertilizer plants to support agriculture and reduce import dependence. With better planning, suitable equipment, and steady technical support, DAP production can become a strong part of the local industry.

As farming continues to develop, demand for DAP fertilizer will remain strong. Step by step, DAP fertilizer manufacturing in Africa will help farmers grow more food, create jobs, and support economic growth across the region.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.