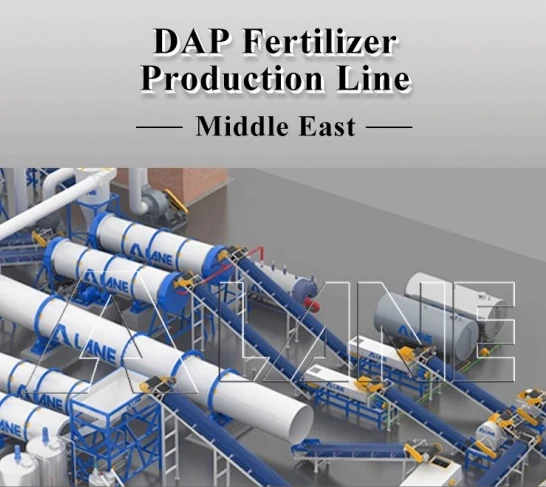

Hey, are you sick of fertilizer prices shooting up every season and eating away at your hard-earned profits? Do late deliveries leave your fields waiting and crops suffering? Have you ever tried producing your own fertilizer, only to face constant machine breakdowns, dusty chaos, and piles of wasted material? These headaches stop today with a dependable DAP fertilizer manufacturing system that puts you back in control.

Too many farmers feel trapped – stuck buying overpriced bags with uneven quality or dealing with cheap setups that fall apart quickly. A properly built DAP fertilizer manufacturing system changes all that. It’s straightforward, saves you serious money, and gives you steady, top-grade fertilizer whenever you need it.

DAP fertilizer is loved worldwide because it delivers the perfect mix of nitrogen and phosphorus. Your crops grow quicker, taller, and produce way more. But paying retail prices means someone else pockets the savings. Owning your own DAP fertilizer manufacturing system lets you make it cheaper and better – straight from raw materials to bags.

The number one frustration? Huge chunks of raw material blocking everything. A powerful vertical crusher kicks off every good DAP fertilizer manufacturing system. It quickly turns big rocks and solids into smooth powder. No clogs, no downtime – production starts fast and stays fast.

Uneven fertilizer is a nightmare – strong in one corner of the field, weak in another. The double screw cone mixer in a reliable DAP fertilizer manufacturing system solves this easily. It thoroughly blends phosphoric acid, ammonia, and additives into perfect slurry. Consistent mix means consistent results in your fields.

Nothing kills momentum like stuff piling up between machines. Belt conveyors are the quiet heroes of the DAP fertilizer manufacturing system. They smoothly carry material from one step to the next – no spills, no stops, just steady flow all day long.

Here’s where it gets exciting! The rotary drum granulator is the heart of the DAP fertilizer manufacturing system. It gently tumbles the wet mix and forms round, even granules. These spread easily with your equipment, store without clumping, and release nutrients slowly for healthier plants.

Fresh granules are soft and sticky – not good for bagging. The hot stove and dryer work together in the DAP fertilizer manufacturing system to blow hot air through and remove moisture fast. You get hard, durable granules without cracks or damage.

Straight-out-of-the-dryer granules are still hot and can stick together. The cooler in the DAP fertilizer manufacturing system drops the temperature gently and quickly. This keeps everything free-flowing and ready for the next step.

Some granules come out too big or too small. The rotary screener sorts them perfectly – good ones move forward, off-size ones go back for recycling. This smart step in the DAP fertilizer manufacturing system means almost no waste and every bag is premium quality.

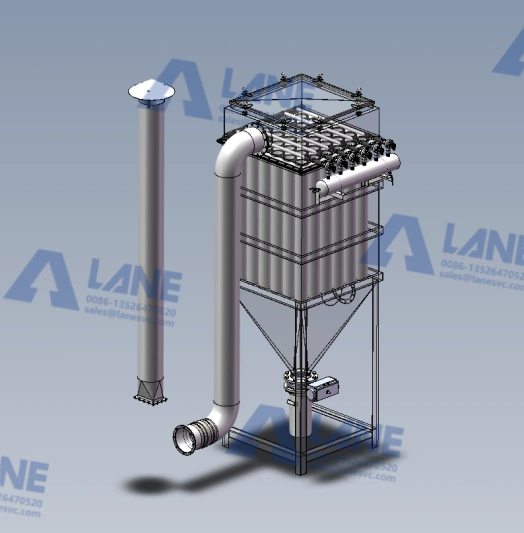

Dust is annoying, unhealthy, and even dangerous. A pulse dust collector runs throughout the DAP fertilizer manufacturing system, catching particles at every stage. Your workshop stays clean, your workers stay safe, and you easily pass environmental checks.

At the end of the line, the packing scale automatically weighs exact amounts into bags – no guesswork, no short bags. The stock bin neatly holds bulk product until you’re ready to sell or use it. The whole DAP fertilizer manufacturing system ends as smoothly as it starts.

Modern systems are built to use less energy and need little maintenance. Motors run efficiently, parts last longer, and breakdowns are rare. Many users cut their fertilizer costs by 30-50% within the first year.

At LANE, we’ve been making fertilizer machinery in China for more than 20 years. Our skilled engineering team listens to your needs and designs a custom DAP fertilizer manufacturing system that fits your space, budget, and goals perfectly. We handle everything – from building the equipment to full installation and training. After that, we’re still here for you: quick repairs, regular maintenance, spare parts, or future upgrades. All our machines meet strict ISO 9001 and CE standards, so you get proven quality and peace of mind. We at LANE specialize in complete production lines – whether DAP, NPK, organic, or compound fertilizer – always built tough, simple to run, and ready to grow with your business.

Farmers who switch to their own DAP fertilizer manufacturing system often tell us the same thing: “I wish I’d done this years ago.” They enjoy steady supply, lower costs, bigger harvests, and extra income from selling surplus fertilizer to neighbors.

Ready to stop worrying about rising prices and start making your own high-quality DAP? A well-planned DAP fertilizer manufacturing system from LANE is easier to set up and run than you think. Take the first step toward bigger profits and better crops today.

Let’s make your farm stronger together!

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.