The global demand for MAP granular fertilizer production line solutions continues to rise as farmers increasingly seek high-phosphate fertilizers with strong agronomic performance and excellent granulation quality. Whether you are upgrading an existing plant or building a new one, understanding how a MAP (Monoammonium Phosphate) fertilizer production line operatesβÄîand how to optimize itβÄîcan significantly improve yield, stability, and profitability.

This article breaks down the full MAP granular production process, key equipment, design considerations, and the advantages of choosing a reliable technology provider such as LANE, a company with more than 15 years of fertilizer engineering expertise.

Core Process Flow of a MAP Granular Fertilizer Production Line

A MAP granular fertilizer production line follows a highly coordinated sequence of chemical reactions, material handling, and mechanical processing steps. Although every plant may differ slightly based on capacity and technology choices, the core workflow remains consistent. Below is a fully rewritten, richer, and more user-friendly version of the process.

1.Raw Material Handling and Accurate Feeding

The production of MAP granular starts with two major raw materials: phosphoric acid and ammonia. Both must be stored and metered with precision.

Key tasks at this stage:

Storing phosphoric acid in corrosion-resistant tanks

Vaporizing or regulating ammonia (liquid or gas)

Stable feeding ensures that the ammoniation reaction remains consistent, which directly influences downstream granulation quality.

2.Controlled Ammoniation Reaction

The heart of every MAP granular fertilizer production line is the ammoniation step. This is where phosphoric acid reacts with ammonia to form MAP slurry. Because the reaction is exothermic, it generates heat that helps pre-dry the material and enhances granulation efficiency later.

Key objectives during ammoniation:

Achieve the correct NβÄ™P balance

Maintain ideal slurry viscosity

Control temperature and free ammonia

Ensure complete neutralization without excessive foaming

Well-controlled ammoniation creates a smooth, adhesive slurry that forms strong granules once introduced into the granulator. LANEβÄôs ammoniation systems are designed to deliver consistent reaction stability even during high-throughput operation.

3.Granulation: Forming MAP Particles

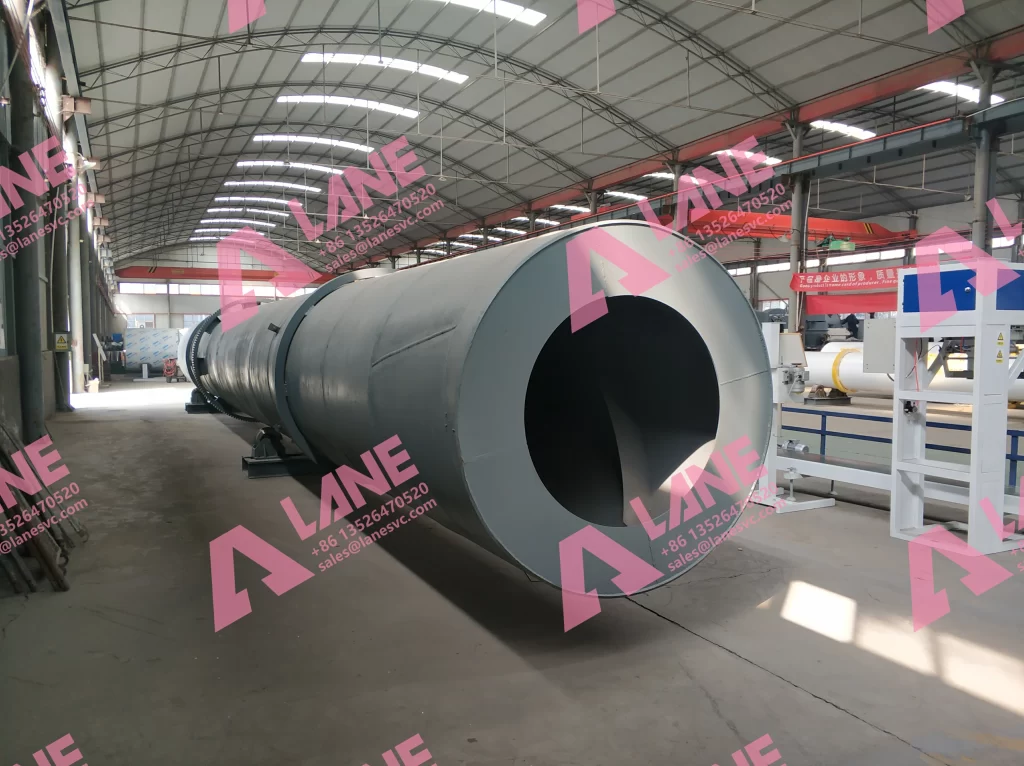

Once the slurry reaches the right consistency, it is fed into a rotary drum granulator or disc granulator depending on plant capacity. Here, the slurry coats recycled seed material, gradually building layers until proper MAP granules are formed.

Granulation depends on:

Drum rotation speed

Recycle ratio

Internal lifter design

Moisture level and slurry temperature

Spray angle and distribution

A well-tuned granulation system ensures the product stays within the preferred 2βÄ™4 mm particle range, improving the market value of the final MAP.

4.Drying to Achieve Stable Moisture

Fresh granules contain high moisture and must be dried before they can be cooled or stored. The rotary dryer reduces moisture from roughly 10βÄ™12% to about 2βÄ™3%.

Drying ensures:

Harder, stronger granules

Better flowability

Reduced caking during storage

LANEβÄôs energy-optimized dryers use stable hot-air distribution to avoid granule cracking and improve efficiency.

5.Cooling for Product Stability

After drying, granules remain hot. Without cooling, they may cake, break easily, or disrupt screening efficiency.

A rotary cooler brings the granules down to near-ambient temperature, typically under 40¬ΑC.

Cooling benefits include:

Enhanced physical strength

Lower dust formation

Better screening performance

Cooling is especially important for MAP because higher temperatures increase the risk of moisture reabsorption.

6.Screening and Particle Size Classification

Vibrating screens sort granules into three categories:

Final product (2βÄ™4 mm)

Oversize granules (crushed and recycled)

Fines (returned to granulation)

This loop ensures minimal waste and consistent quality.

7.Optional Coating for Anti-Caking Protection

Some regionsβÄîespecially humid climatesβÄîrequire additional coating to ensure the MAP granules remain free-flowing during storage and transport. A coating machine applies a thin layer of anti-caking agent, improving the product’s shelf life and commercial appeal.

8.Packaging and Final Product Handling

Once screened and optionally coated, MAP granules are delivered to the packing line. Automated packing machines ensure accurate filling for:

25 kg bags

50 kg bags

1,000 kg jumbo bags

LANEβÄôs packaging systems are designed to work dust-free and provide consistent accuracy to reduce product loss.

Case Example: 12 t/h MAP Granular Fertilizer Production Line

A large agricultural distributor in South America approached LANE Company, seeking to establish a 12 t/h MAP granular fertilizer production line. This would help reduce reliance on imported MAP and enable better control over product quality. The farmers in this region have a high demand for high-phosphorus fertilizers, and the customers require a factory that can operate stably under local high humidity and fluctuating energy prices.

LANEβÄôs engineering team designed a production line centered on precise ammoniation control, stable granulation, and energy-efficient drying and cooling. The system integrates an ammoniation reactor with automatic acidβÄ™ammonia ratio regulation, a corrosion-resistant rotary drum granulator, and a combined dryerβÄ™cooler setup optimized for humid climates. An enclosed screening system and an anti-caking coating drum were included to ensure uniform particles and better storage performance. All major sectionsβÄîfeeding, ammoniation, granulation, drying, cooling, screening, and baggingβÄîwere linked through a PLC control platform, allowing real-time monitoring with only a few operators per shift.

Once installed and commissioned, the line quickly reached its target capacity. Output stabilized between 12 and 13 t/h, and over 90% of granules consistently fell within the sought-after 2βÄ™4 mm range. The final product maintained a moisture content near 2βÄ™3%, and even after prolonged storage, caking remained minimal thanks to the optimized cooling and coating stages. Energy usage also improved compared with their existing NPK line, with noticeably lower fuel consumption in the dryer and reduced electrical load across the plant.

The client stated that this new production line not only met their technical expectations, but also helped them consolidate their position in the regional fertilizer market. The operators were highly complimentary of the automation features, while the maintenance personnel noted a reduction in wear-related issues. The distributors preferred the higher hardness and better fluidity of the MAP particles. Thanks to stable production and consistent product quality, this factory quickly became one of the most reliable and profitable production lines for the customers.

Why Choose LANE for Your MAP Granular Fertilizer Production Line?

20+ Years of Engineering Experience: LANE specializes in fertilizer plantsβÄîincluding MAP, DAP, NPK, organic, and compound fertilizer production systems.

Turnkey Solutions: From design and fabrication to installation, commissioning, and training.

High-Quality Materials: We use thick carbon steel or stainless steel, anti-corrosion linings, and reliable motors.

Smart Automation Options: PLC control, automatic dosing, real-time monitoring.

Custom Layouts: 3βÄ™5 t/h small plantsψĹ10βÄ™20 t/h medium plantsψĹ30βÄ™50 t/h large industrial plants

Fast Global Delivery & After-Sales Service: LANE maintains global customers in the Middle East, Southeast Asia, South America, and Africa.

Conclusion

A MAP granular fertilizer production line provides a reliable way to produce high-quality phosphate fertilizer for modern agriculture. By integrating efficient ammoniation, controlled granulation, optimized drying/cooling, and automated packaging, producers can achieve stable output, strong granule quality, and excellent market competitiveness.

With LANEβÄôs engineering experience and turnkey approach, investors gain not only equipment but also long-term productivity and technical support.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.