MAP helps increase crop yields in modern field agriculture, especially as farmers look for fertilizers that are easy to use and deliver steady results. In large-scale farming, fertilizer efficiency matters as much as crop genetics and soil management. MAP fertilizer has become a common choice in many countries because it works well in different climates and soil conditions while fitting smoothly into mechanized farming systems.

MAP helps increase crop yields because it provides two essential nutrients at the same time. Phosphorus supports root development and early plant strength, while nitrogen helps crops build healthy leaves and stems. MAP fertilizer dissolves well in soil moisture, allowing nutrients to reach plant roots quickly. This makes it especially useful as a base fertilizer for field crops such as wheat, corn, rice, and soybeans.

MAP helps increase crop yields by improving early root growth. When roots grow deeper and stronger, crops can absorb water and nutrients more efficiently. This early advantage often leads to better resistance to drought and other stress later in the season. Farmers often notice more uniform crop growth when MAP fertilizer is used correctly.

MAP helps increase crop yields throughout the growing season, not just at planting time. The steady nutrient supply supports balanced growth, helping crops mature evenly. This can improve harvest efficiency and crop quality, which is important for both food crops and industrial raw materials.

MAP helps increase crop yields in large fields because it is easy to store, transport, and spread. Granular MAP fertilizer flows smoothly through mechanical spreaders and blends well with other fertilizers. This makes it ideal for large-scale farming operations that rely on modern equipment and tight schedules.

MAP helps increase crop yields, but only when the fertilizer is produced with consistent quality. To achieve this, a complete MAP fertilizer production line is required. This production line includes several clearly defined machine types, each with a specific role in turning raw materials into finished fertilizer granules.

Raw Material Batching System

This system is used to accurately measure and feed raw materials into the production line. Stable batching ensures that each batch of MAP fertilizer has the same nutrient content.

Fertilizer Mixer

The mixer blends raw materials evenly before granulation. Good mixing helps ensure uniform nutrient distribution in every fertilizer granule.

Granulator (Rotary Drum Granulator or Disc Granulator)

The granulator shapes the mixed material into round fertilizer granules. Drum granulators are often used for large-capacity production, while disc granulators are suitable for flexible and medium-scale lines.

Rotary Dryer

After granulation, fertilizer granules contain moisture. The rotary dryer removes excess water, improving granule strength and storage performance.

The cooler reduces the temperature of dried granules. Cooling prevents caking and helps maintain granule quality during storage and transportation.

Screening Machine

The rotary screening machine separates qualified granules from oversized or undersized ones. Unqualified particles are returned to the granulator for reuse.

Coating Machine (Optional)

Some production lines include a coating machine to apply an anti-caking layer or nutrient coating, improving fertilizer appearance and performance.

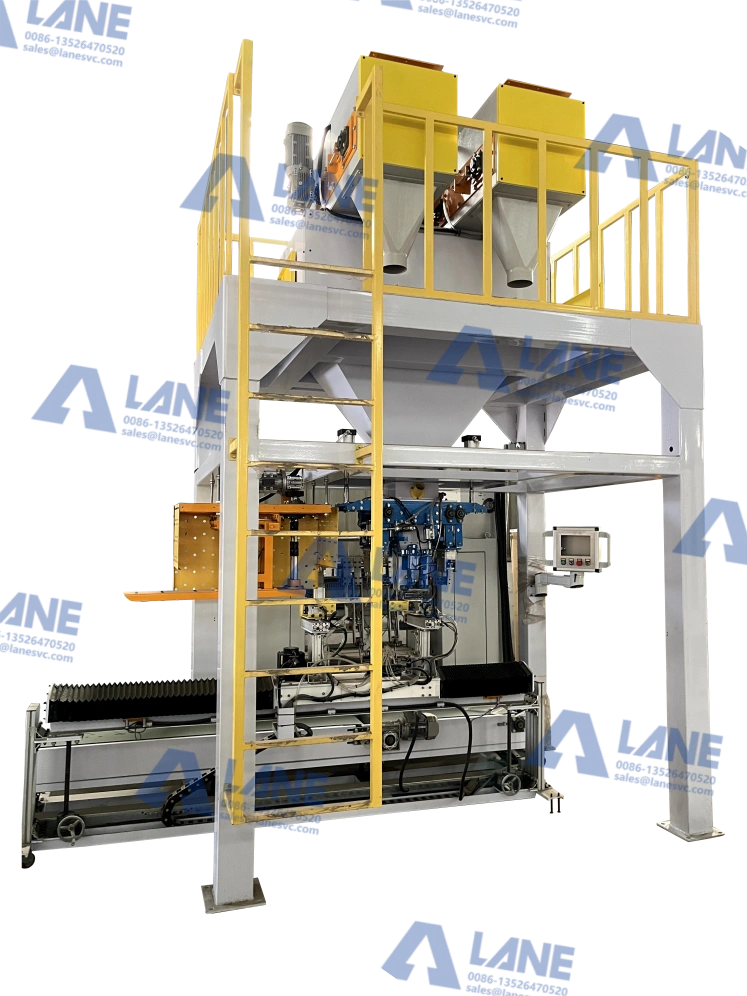

Automatic Packaging Machine

The packaging machine weighs and packs finished MAP fertilizer into bags, preparing it for sale or shipment.

MAP helps increase crop yields, and efficient production ensures stable supply. A well-designed fertilizer production line improves output, reduces material waste, and lowers energy consumption. Layout planning, equipment matching, and automation level all play an important role in long-term operation.

MAP helps increase crop yields, and at our company, we support this goal from the production side. We have over 20 years of experience in fertilizer machinery manufacturing in China. Our professional engineering team designs and manufactures customized fertilizer equipment based on customer needs and installs complete production lines. We provide one-stop services, including installation, after-sales support, maintenance, troubleshooting, and upgrades. Our equipment meets ISO9001 and CE quality standards. We specialize in machinery for organic fertilizer, compound fertilizer, and liquid fertilizer, offering reliable solutions for different fertilizer producers.

MAP helps increase crop yields by delivering balanced nutrition to crops and supporting modern farming practices. With the right fertilizer production equipment and a well-planned production line, manufacturers can produce high-quality MAP fertilizer that meets the needs of farmers worldwide. This strong connection between factory and field is key to sustainable agricultural development.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.