The diammonium phosphate production process plays an important role in the global fertilizer market. Diammonium phosphate, often known as DAP, is one of the most widely used phosphate fertilizers in the world. It supplies nitrogen and phosphorus at the same time, which makes it very popular in modern agriculture.

As food demand continues to grow, fertilizer producers face increasing pressure. They need higher output, stable quality, and lower operating costs. Because of this, more companies are paying attention not only to the product itself, but also to how the production line is designed and managed.

This article looks at the production process from a project point of view. It focuses on equipment selection, process features, and practical operation, helping readers better understand how a modern DAP plant works in real life.

Diammonium phosphate is suitable for many types of soil and crops. It dissolves quickly and releases nutrients efficiently. Farmers often choose it because it is easy to apply and shows fast results.

From a production perspective, DAP is also attractive. The raw materials are well known. The process is mature. With proper design, the production line can run continuously for long periods. This stability makes the diammonium phosphate production process a solid investment option for fertilizer manufacturers.

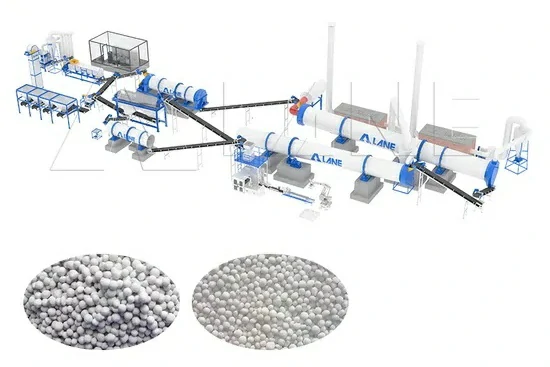

A typical production line follows a clear sequence. Each section has a simple task, but all sections must work together smoothly.

The process starts with raw material preparation. Ammonia and phosphoric acid are stored and delivered to the reaction system. Accurate control at this stage helps ensure stable chemical reaction.

After reaction, the material enters the granulation section. Here, fine particles are formed into uniform granules. These granules then move through drying, cooling, and screening stages before final packing.

This continuous flow is one of the main strengths of the diammonium phosphate production process. It reduces handling time and improves overall efficiency.

To run a successful diammonium phosphate production process, selecting the right machinery is just as important as the chemical formula itself. To optimize your diammonium phosphate production process, you need heavy-duty machinery built for chemicals and heat:

A production line does not need to be complicated to be effective. What matters is reliability and proper matching.

The reaction unit is the starting point. It must be well sealed and easy to control. Stable reaction conditions help reduce waste and improve product consistency.

The granulator is the heart of the line. Many plants choose rotary drum granulators because they are durable and easy to maintain. They also work well with large capacities.

Dryers and coolers handle temperature control. Drying removes excess moisture, while cooling protects granules during storage and transport. These machines are usually designed for continuous operation.

Screening equipment improves product appearance and quality. It ensures that only qualified granules reach the packing stage.

A well-designed diammonium phosphate production process has several clear characteristics.

First, it runs smoothly. Material moves in one direction with minimal interruption. Second, it is easy to adjust. Operators can fine-tune parameters such as moisture and temperature. Third, it supports long-term operation with low maintenance needs.

Dust control and environmental protection are also important. Modern plants include dust collectors and sealed systems to keep the working area clean and safe.

Running a production line is not just about machines. People and management play a big role.

Operators need clear instructions. Simple control systems help reduce mistakes. Routine inspection helps detect small problems early.

A stable diammonium phosphate production process allows operators to focus on quality instead of constant troubleshooting. This improves both efficiency and morale inside the plant.

Energy use is a major cost factor. Efficient burners, proper airflow, and heat recovery systems help reduce fuel consumption.

Material recycling also improves efficiency. Oversized or undersized granules are returned to the system instead of being wasted. This closed-loop design is common in modern fertilizer plants.

All these measures make the diammonium phosphate production process more competitive in the long run.

Before construction begins, good planning is essential. Site size, local climate, and raw material supply all affect layout design.

A compact layout reduces material transfer distance. It also simplifies operation and maintenance. Experienced engineers can design a line that balances capacity and space.

This stage has a strong impact on the future performance of the diammonium phosphate production process.

At LANE, we have worked in fertilizer machinery manufacturing for more than 20 years. We understand how different production lines operate under real conditions.

Our company provides customized solutions based on customer needs. We design, manufacture, and install complete fertilizer production lines. We also support organic fertilizer, compound fertilizer, and liquid fertilizer equipment.

We focus on practical design, stable operation, and long service life. Our equipment meets ISO9001 and CE standards, ensuring reliable quality. From installation to after-sales support, we stay involved and help our clients keep their lines running smoothly.

Installation is a key phase of any project. Proper alignment and testing help avoid future problems.

We guide customers through commissioning and trial operation. Training helps operators understand daily tasks and basic maintenance.

Long-term support is part of our service. When the diammonium phosphate production process runs smoothly, production targets are easier to achieve.

The fertilizer industry continues to change. Automation and digital monitoring are becoming more common. Producers want smarter systems and cleaner production.

Future production lines will focus on flexibility. They will be easier to upgrade and adapt to market needs. Energy efficiency and environmental protection will remain key priorities.

The diammonium phosphate production process is a proven and reliable system when designed and operated correctly. With proper equipment, thoughtful layout, and experienced support, it can deliver stable quality and long-term value.

For companies planning new projects or upgrades, understanding the process is essential. Choosing the right equipment partner helps ensure smooth operation, efficient production, and sustainable growth over time.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.