When planning a fertilizer investment project, MAP fertilizer factory equipment is often one of the first and most important topics discussed. Monoammonium phosphate fertilizer has stable global demand, and many producers see it as a reliable product with long-term market value. However, the success of a MAP fertilizer plant depends largely on how well the equipment system is designed and integrated.

Unlike small workshop-style production, a modern factory relies on a complete and well-matched equipment lineup. Each machine has a clear role, and together they form a smooth, continuous production process that supports efficiency, quality, and cost control.

Every MAP fertilizer plant begins with raw materials, mainly phosphoric acid and ammonia. Proper handling of these materials is essential for safety and stable production. High-quality MAP fertilizer factory equipment usually includes dedicated storage tanks, transfer pumps, and accurate feeding systems.

Storage tanks are designed to resist corrosion and handle long-term use. Feeding systems control material flow with precision, ensuring the reaction process remains balanced. This not only improves product quality but also reduces material waste, which directly lowers production costs.

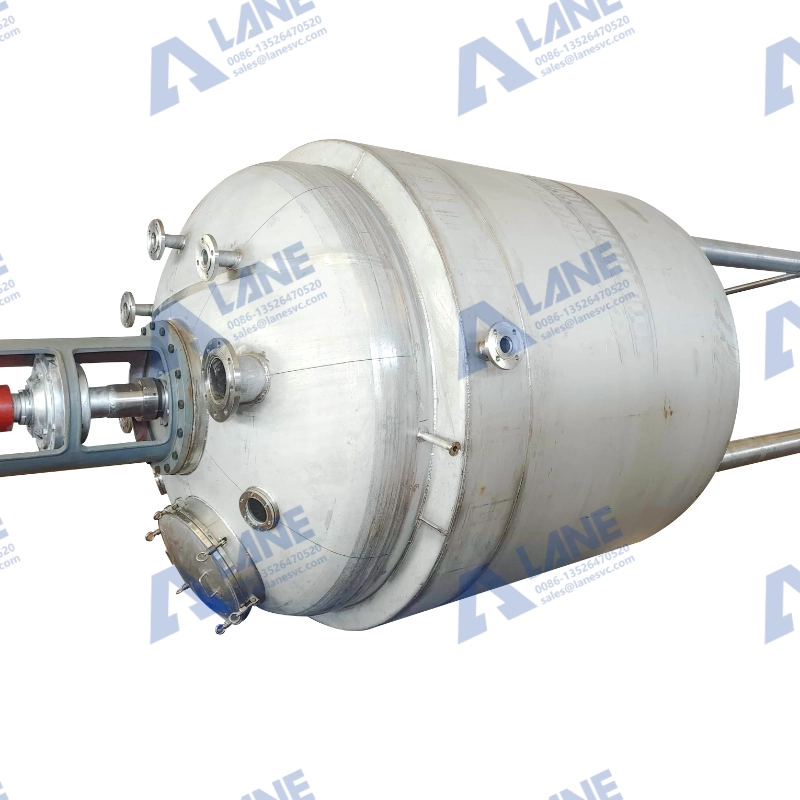

The reaction system is the core of the entire production line. In this step, phosphoric acid and ammonia are neutralized to form MAP slurry. Well-designed reactors are a key part of reliable MAP fertilizer factory equipment.

A stable reactor allows even mixing and consistent temperature control. This helps avoid sudden fluctuations that could affect product composition. Good reaction efficiency also means higher output with the same amount of raw material, which improves overall profitability.

After the reaction, the material moves to the granulation stage. Granulation is one of the most visible parts of MAP fertilizer factory equipment, because it directly affects product appearance and usability.

Granulators (rotary drum granulator or double roller granulator, etc.) shape the material into uniform particles that are easy to store, transport, and apply in the field. Consistent granule size also improves market acceptance, as customers prefer fertilizer that spreads evenly and dissolves well.

Different granulation methods can be selected based on capacity and product requirements. A flexible granulation system allows future adjustments without major changes to the production line.

Freshly granulated fertilizer contains moisture and heat. Drying and cooling equipment is therefore essential in any MAP fertilizer factory equipment setup.

Dryers remove excess moisture, increasing product strength and shelf life. Coolers then reduce temperature, preventing caking during storage. These systems work together to ensure the fertilizer remains stable from factory to farm.

Efficient drying and cooling also reduce energy consumption, which helps keep operating costs under control.

Screening systems separate qualified granules from oversized or undersized particles. This step is often overlooked, but it plays a major role in product consistency. Modern MAP fertilizer factory equipment includes screening machines that work continuously with minimal downtime.

Unqualified particles are sent back into the system for reprocessing. This recycling process reduces waste and improves raw material utilization, directly contributing to higher economic efficiency.

The final step is packaging. Automated packaging machines weigh, fill, and seal fertilizer bags with high accuracy. In a complete MAP fertilizer factory equipment line, packaging systems are designed to match production capacity and reduce manual labor.

Good packaging improves product appearance and protects fertilizer during transport. It also helps factories respond quickly to market demand by offering different bag sizes.

Modern fertilizer plants rely heavily on automation. Control systems connect all parts of the MAP fertilizer factory equipment into one coordinated operation.

Operators can monitor temperature, pressure, and material flow in real time. Automation improves safety, reduces labor intensity, and ensures stable product quality. Over the long term, it also lowers maintenance costs by detecting issues early.

Investing in a full set of MAP fertilizer factory equipment brings clear economic benefits. A well-designed production line runs smoothly, with fewer shutdowns and lower repair costs.

High efficiency means more output per day, while precise control reduces raw material loss. Together, these factors shorten the return-on-investment period and improve long-term profitability.

In addition, modern equipment supports large-scale production, allowing factories to compete more effectively in regional and international markets.

Another advantage of modern MAP fertilizer factory equipment is flexibility. Production lines can often be adjusted to produce different fertilizer grades or related products.

This adaptability allows factory owners to respond to market changes without rebuilding the entire plant. It protects the initial investment and supports sustainable business growth.

At LANE, we have over 20 years of focused experience in fertilizer machinery manufacturing. Our company has long specialized in fertilizer equipment and production line solutions.

We design and customize MAP fertilizer factory equipment according to customer capacity, site conditions, and market needs. Our professional engineering team handles equipment manufacturing, full production line installation, and on-site commissioning.

We also provide complete after-sales support, including maintenance guidance, troubleshooting, and system upgrades. Our equipment meets international standards such as ISO9001 and CE, ensuring stable quality and reliable performance for long-term operation.

Building a MAP fertilizer plant is not just about choosing a product; it is about choosing the right MAP fertilizer factory equipment. From raw material handling to final packaging, every machine plays a role in efficiency, quality, and profit.

With proper planning, reliable equipment, and professional support, a MAP fertilizer factory can become a stable and competitive business that delivers lasting economic value.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.