In the world of modern agriculture, the secret to a bountiful harvest often lies beneath the surface of the soil. For farmers and agricultural business owners, maximizing peanut production is a top priority. Peanuts are a staple crop globally, providing essential oils, proteins, and snacks for billions. However, growing them successfully requires a precise balance of nutrients. This is where Diammonium Phosphate (DAP) comes into play. By establishing a professional DAP production line, companies can provide the specific nutrients needed to skyrocket peanut production levels and ensure food security.

When we talk about peanut production, we aren’t just talking about planting seeds and waiting for rain. Peanuts are heavy feeders, especially when it comes to phosphorus. Unlike some other crops, peanuts have a unique growth habit鈥攖hey flower above ground but develop their pods below the soil. This process requires a massive amount of energy.

DAP fertilizer is one of the most popular choices because it is highly soluble and quickly dissolves in the soil to release plant-available phosphate and ammonium. This immediate boost is what helps young plants establish strong roots. Strong roots lead to healthy plants, and healthy plants are the foundation of high-volume peanut production. Without the right fertilizer, the soil can become depleted, leading to smaller yields and poor-quality nuts.

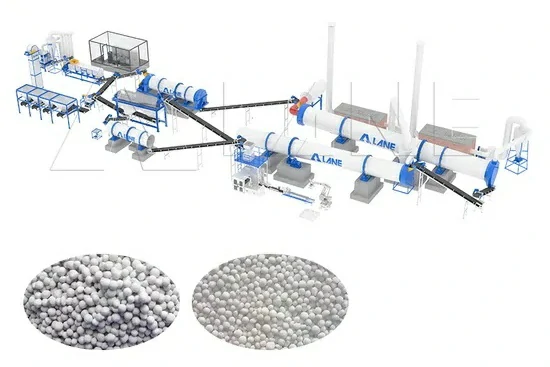

Setting up a production line specifically designed to support peanut production involves several sophisticated steps. It is not just about mixing chemicals; it is about creating a consistent, easy-to-spread product that farmers can rely on.

The process usually begins with the reaction of phosphoric acid with ammonia. This creates a slurry that is then processed into granules. These granules are easier for farmers to handle and spread evenly across large fields. Consistency in these granules is key. If the fertilizer is uneven, the peanut production across a single farm will be patchy, with some areas thriving and others struggling.

To build a factory that truly makes a difference in peanut production, you need a suite of reliable machines. Each piece of equipment plays a vital role in ensuring the final product is of the highest quality.

The first step is getting the recipe right. Different soils require different ratios of nitrogen and phosphorus. An automated batching system ensures that every bag of fertilizer produced for peanut production contains exactly what the label says. This precision prevents “nutrient burn” and ensures the plants get exactly what they need.

This is where the magic happens. A double roller granulator or rotary drum granulator takes the raw materials and turns them into uniform pellets. For peanut production, granules are preferred over powders because they release nutrients more slowly and don’t blow away in the wind.

Once the granules are formed, they are wet and hot. A rotary dryer uses heat to remove moisture, making the pellets hard and durable. Following this, a cooling machine brings the temperature down so the fertilizer can be bagged immediately. This step is crucial; if the fertilizer is packed while warm, it will clump together, making it useless for farmers trying to improve their peanut production.

Not every granule comes out the perfect size. A rotary screening machine acts like a giant sieve, separating the pellets that are too large or too small. The “perfect” pellets are sent to the packing station, while the others are sent back to the start to be reworked. This ensures that the product used for peanut production is consistent in size, which is vital for mechanical spreaders on large farms.

Finally, a thin layer of oil or wax is often applied in a coating machine to prevent dust and moisture absorption. Then, an automatic packing machine weighs and seals the bags. High-quality packaging ensures that the fertilizer stays fresh and effective until it reaches the field to boost peanut production.

Owning the machinery is only half the battle. To run a successful line that supports global peanut production, you must pay attention to the details of operation.

Monitor Humidity: Fertilizer is very sensitive to moisture. If your factory is too humid, the machines will clog. Maintaining a dry environment is essential for a steady flow of product.

Calibration is Key: Regularly calibrate your scales and batching systems. Even a small error in the nutrient mix can lead to a significant drop in the effectiveness of the fertilizer for peanut production.

Worker Safety: Fertilizer production involves chemicals and dust. Ensure all workers have the right safety gear and that the factory has excellent ventilation. A safe factory is a productive factory.

At LANE, we don’t just sell machines; we provide solutions that drive the future of agriculture. We know that the ultimate goal of our clients is to increase peanut production and profitability. Here is how we support that mission:

Our Deep Industry Roots We have been a leader in the Chinese fertilizer machinery manufacturing sector for more than 20 years. This isn’t just a business for us; it鈥檚 a craft we have perfected over two decades. We have seen the industry evolve and have consistently stayed ahead of the curve, helping our clients adapt to new farming challenges.

Custom Engineering and Installation We know that every project is different. Our professional engineering team works closely with you to design a production line that fits your specific space and budget. We don’t believe in “one size fits all.” We can manufacture, deliver, and install an entire production line from scratch, tailored specifically to create the best fertilizers for peanut production.

A Full Suite of Services When you partner with us, you are never alone. We provide one-stop, full-scale service. This includes everything from the initial site planning and equipment installation to comprehensive after-sales support. If a machine goes down or you need a part replaced, our team is ready to troubleshoot and provide maintenance or upgrades. We ensure your production line remains stable and efficient year after year.

Quality You Can Trust Quality is at the core of everything we do. Our equipment is manufactured to meet ISO9001 and CE international quality standards. This means when you buy from us, you are investing in machinery that is safe, durable, and reliable. Reliable machines mean less downtime and more fertilizer produced to help with peanut production.

Versatile Product Range While we excel in DAP lines, we are also experts in organic, compound, and liquid fertilizer machinery. This versatility allows us to help you expand your business as the market changes. Whether you are focusing on traditional farming or the growing organic sector, we have the tools you need to succeed.

The demand for peanuts is only going up. From peanut butter in the West to peanut oil in the East, this crop is a global necessity. To meet this demand, the industry must move toward more efficient fertilization methods. A high-tech DAP production line is the bridge between traditional farming and modern, high-yield peanut production.

By reducing waste and ensuring that every gram of fertilizer is packed with nutrients, these production lines help farmers save money and protect the environment. Over-fertilizing or using poor-quality products can damage the soil, but a precise DAP application supports sustainable peanut production for generations to come.

Building a fertilizer plant is a big step, but it is one of the most rewarding investments in the agricultural sector. As global food needs grow, the role of high-quality fertilizer in peanut production cannot be overstated. With the right equipment and a partner like LANE, you can be confident that your production line will be a success.

We take pride in our history and our ability to help our clients grow. If you want to see a real increase in peanut production in your region, starting with the right fertilizer is the way to go. Our expertise, combined with your vision, can create a powerful force for agricultural growth.

In conclusion, the path to better peanut production is paved with quality nutrients and reliable machinery. From the initial crushing of raw materials to the final bagging of the granules, every step in the DAP production line matters. By choosing high-quality equipment and maintaining it well, you can ensure a steady supply of top-tier fertilizer for the market.

Remember, the goal is always to help the farmer. When the farmer succeeds in increasing their peanut production, the entire supply chain wins. Let us help you build the machines that feed the world.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.