In recent years, fertilizer producers have been looking for ways to improve product quality while keeping production stable and cost-effective. One important trend is the use of DAP in NPK fertilizer blending plant, which helps manufacturers achieve better nutrient ratios and stronger granules.

Diammonium phosphate (DAP) is widely used because it provides both nitrogen and phosphorus in a concentrated form. When blended into NPK fertilizer, it improves nutrient distribution and enhances the performance of the final product in the field.

From small factories to large industrial lines, the use of DAP in NPK fertilizer blending plant is becoming more common. But to get the best results, it is important to understand the process, the machines involved, and the key technical points.

DAP is not just another raw material. It plays a special role in NPK fertilizer production.

First, it provides two essential nutrients at the same time. Second, it improves the physical structure of fertilizer granules. Third, it helps stabilize the nutrient formula in blended products.

In practical production, the use of DAP in NPK fertilizer blending plant requires careful control of proportion, moisture, and mixing time. If these factors are not managed properly, the final product may have uneven nutrients or weak granules.

That is why many producers focus on optimizing the use of DAP in NPK fertilizer blending plant as part of their process improvement strategy.

To achieve stable and efficient production, a complete NPK blending line usually includes several key machines.

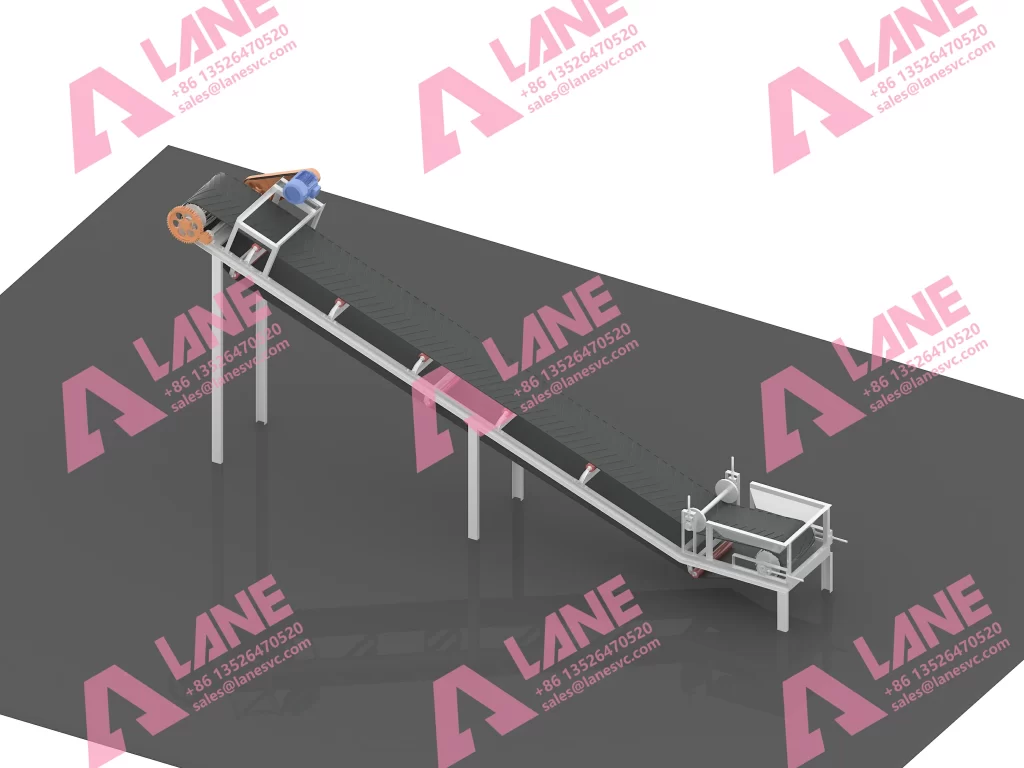

1) Raw Material Handling Equipment

Raw materials such as DAP, urea, potassium chloride, fillers, and additives must be stored and transported properly.

Typical equipment includes:

These machines ensure smooth material flow for the use of DAP in NPK fertilizer blending plant.

2) Automatic Batching System

Accurate batching is essential for NPK fertilizer quality.

The batching system controls the ratio of each material. It ensures that DAP is added in the correct amount during the use of DAP in NPK fertilizer blending plant.

Modern systems often use electronic scales and PLC control, which help reduce errors and improve consistency.

3) Mixing Machine

The mixer is one of the most important machines in the production line.

Common types include:

The mixer ensures that DAP and other materials are evenly distributed. Without proper mixing, the use of DAP in NPK fertilizer blending plant cannot achieve the desired nutrient uniformity.

4) Granulation Equipment

If the plant produces granulated NPK fertilizer, granulation machines are needed.

Typical options include:

During granulation, the use of DAP in NPK fertilizer blending plant affects granule strength and shape. Proper granulation technology helps create uniform and durable pellets.

5) Drying and Cooling System

After granulation, fertilizer pellets must be dried and cooled.

Equipment usually includes:

These machines help stabilize the product after the use of DAP in NPK fertilizer blending plant, ensuring good storage and transportation performance.

6) Screening and Packaging System

Finally, the fertilizer is screened to separate qualified granules from fine powder and oversized particles.

Qualified products are sent to automatic packaging machines. This step completes the production process built around the use of DAP in NPK fertilizer blending plant.

Even with advanced machines, successful production depends on proper operation and control.

Moisture Control

DAP is sensitive to moisture. Too much moisture can cause caking, while too little moisture can reduce granulation efficiency.

Therefore, moisture control is crucial in the use of DAP in NPK fertilizer blending plant.

Temperature Management

During drying and granulation, temperature must be carefully controlled. Excessive heat may affect DAP stability, while low temperature may lead to weak granules.

Stable temperature is another key factor in the use of DAP in NPK fertilizer blending plant.

Material Compatibility

Different raw materials may react with each other. Producers must ensure that DAP is compatible with other components in the formula.

Proper material selection improves the efficiency of the use of DAP in NPK fertilizer blending plant.

Equipment Coordination

Each machine in the production line must work in harmony. If one machine operates inefficiently, the whole process may be affected.

A well-designed production line is essential for the smooth use of DAP in NPK fertilizer blending plant.

There are several reasons why manufacturers increasingly adopt this approach.

First, DAP helps achieve balanced nutrient formulas. Second, it improves granule quality and appearance. Third, it supports flexible production for different market needs.

As a result, the use of DAP in NPK fertilizer blending plant has become a practical and competitive solution for fertilizer producers worldwide.

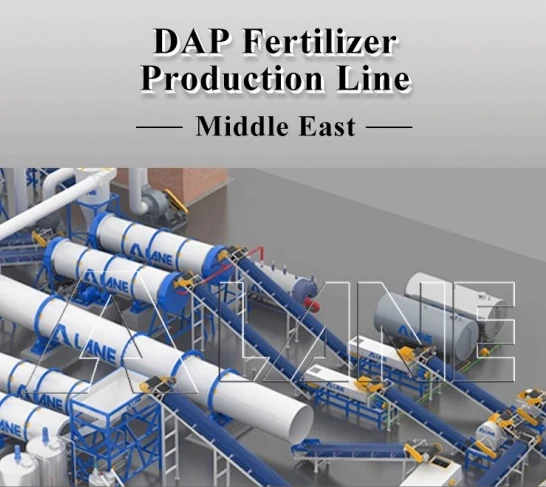

At LANE, we have worked in fertilizer machinery manufacturing for more than 20 years. Over time, we have accumulated deep industry knowledge and practical experience in designing production lines.

We understand that every factory is different. That is why we provide customized solutions for clients who want to optimize the use of DAP in NPK fertilizer blending plant.

Our professional engineering team designs, manufactures, and installs complete fertilizer production lines based on real production needs. From the first layout design to final commissioning, we support every step of the project.

We also offer one-stop services, including equipment installation, technical training, maintenance, troubleshooting, and system upgrades. Our goal is to ensure that each production line operates efficiently and stably.

Quality is always our priority. Our equipment meets international standards such as ISO9001 and CE. This means our machines are reliable, safe, and suitable for global markets.

We specialize in machinery for organic fertilizer, compound fertilizer, and liquid fertilizer production. With a complete product range and strong technical capability, we help clients build modern production systems centered on efficient and stable processing.

When clients plan to improve the use of DAP in NPK fertilizer blending plant, we work closely with them to find the most suitable equipment configuration and process design.

The fertilizer industry is changing rapidly. Automation, digital control, and energy efficiency are becoming key trends.

In the future, smart batching systems, intelligent monitoring, and environmentally friendly technologies will further improve the use of DAP in NPK fertilizer blending plant.

Producers who invest in modern equipment and optimized processes will gain stronger competitiveness in the market.

The use of DAP in NPK fertilizer blending plant is not just a technical choice—it is a strategic decision for improving product quality and production efficiency.

By selecting the right machines, controlling key parameters, and designing a well-coordinated production line, manufacturers can achieve stable and high-quality NPK fertilizer production.

With our long-term experience, professional engineering team, and comprehensive service system, we are ready to support producers who want to upgrade their production lines and fully benefit from advanced blending technology.

If you are planning to enhance your production process, understanding the use of DAP in NPK fertilizer blending plant is a strong first step toward building a more efficient and competitive fertilizer factory.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Copyright © Henan Lane Heavy Industry Machinery Technology Co., Ltd.